Method for cyclically applying sludge wastewater to sludge dehydration

A technology for sludge dehydration and wastewater recycling, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of high water content in sludge and high treatment cost, and achieve high dehydration efficiency, The effect of saving fresh water consumption and avoiding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be clearly and completely described below in conjunction with examples, but these examples should not be construed as limiting the present invention.

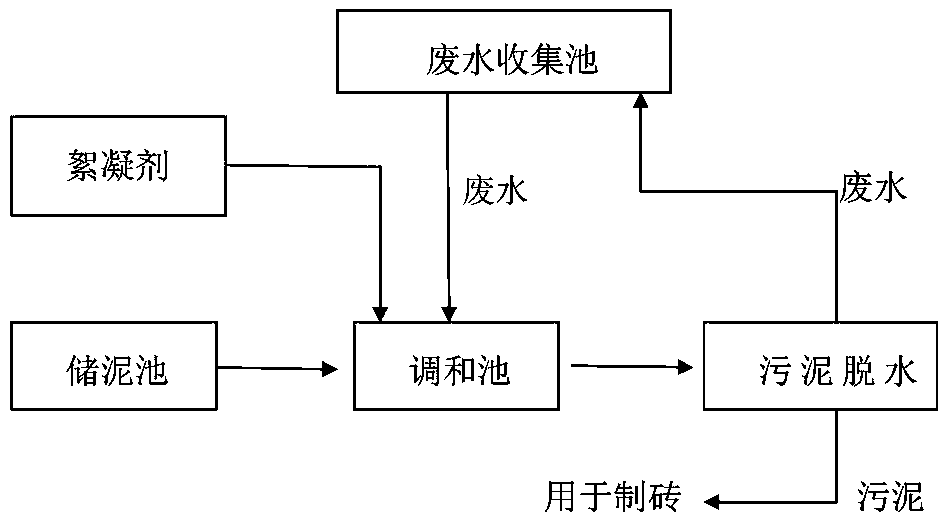

[0011] A method of applying sludge waste water circulation to sludge dewatering, comprising the following steps:

[0012] 1) Collect waste water: the waste water generated after the sludge enters the filter press for dehydration is collected into the waste water collection pool after sedimentation and set aside;

[0013] 2) Dilute pulping: put the sludge with 80% water content in the conditioning tank, add the wastewater collected in step 1) to the conditioning tank, dilute the sludge to a water content of 93±1%, and add the liquid that is stirred evenly The flocculant, the flocculant is made of polymer cationic polyacrylamide, and it is added according to 10%-15% of the absolute dry weight of the sludge. After adding, stir for 15 minutes, so that the sludge and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com