Tension adjusting device and enameled wire production line

A tension adjustment device and tension adjustment wheel technology, which are applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, etc., can solve the problems of surface damage of bare copper wires, small pay-off reels, affecting the normal operation of the annealing process, etc. , to achieve the effect of reducing aggregation and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

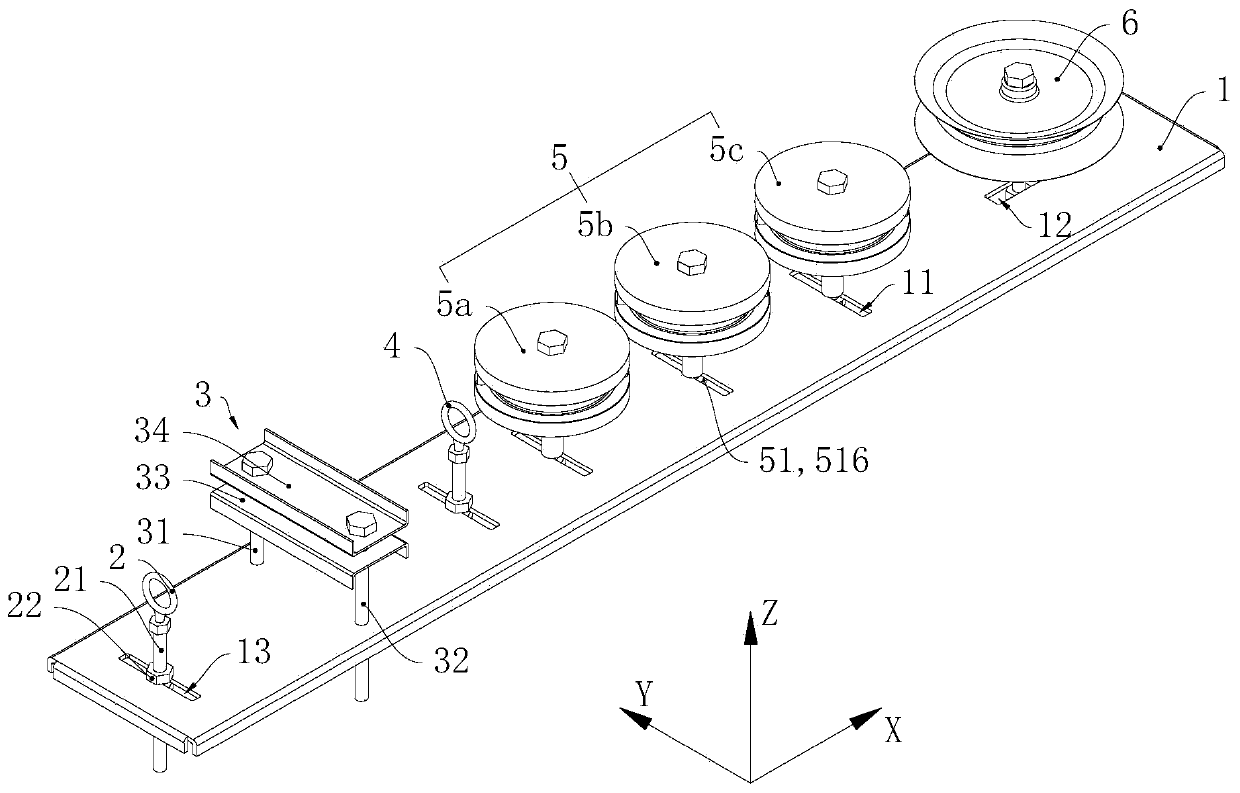

[0031] The production process of enameled wire includes multiple processes such as unwinding, annealing, cooling, drying, painting, baking, cooling, lubrication, and winding in sequence, among which unwinding, annealing, cooling, drying, and painting are important The processing procedure of the bare copper wire, the enameled wire production line of the present embodiment includes a pay-off reel, an annealing device and the tension adjustment device of the present embodiment, a bare copper wire is wound on the pay-off reel, and the bare copper wire is introduced after being released from the pay-off reel Annealing is carried out in the annealing device, and the annealed bare copper wire enters the subsequent cooling, drying, painting, baking, cooling, lubricating, and winding in order to complete the production of enameled wire.

[0032] In the enameled wire production line of the present embodiment, the tension adjusting device of the present embodiment is provided between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com