Packaging bag

A packaging bag and bag body technology, applied in the field of packaging bags, can solve the problems of time-wasting, intermixing, and inflexibility of corner cutting knives, and achieve the effects of saving time, avoiding intermixing, and being flexible and convenient to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

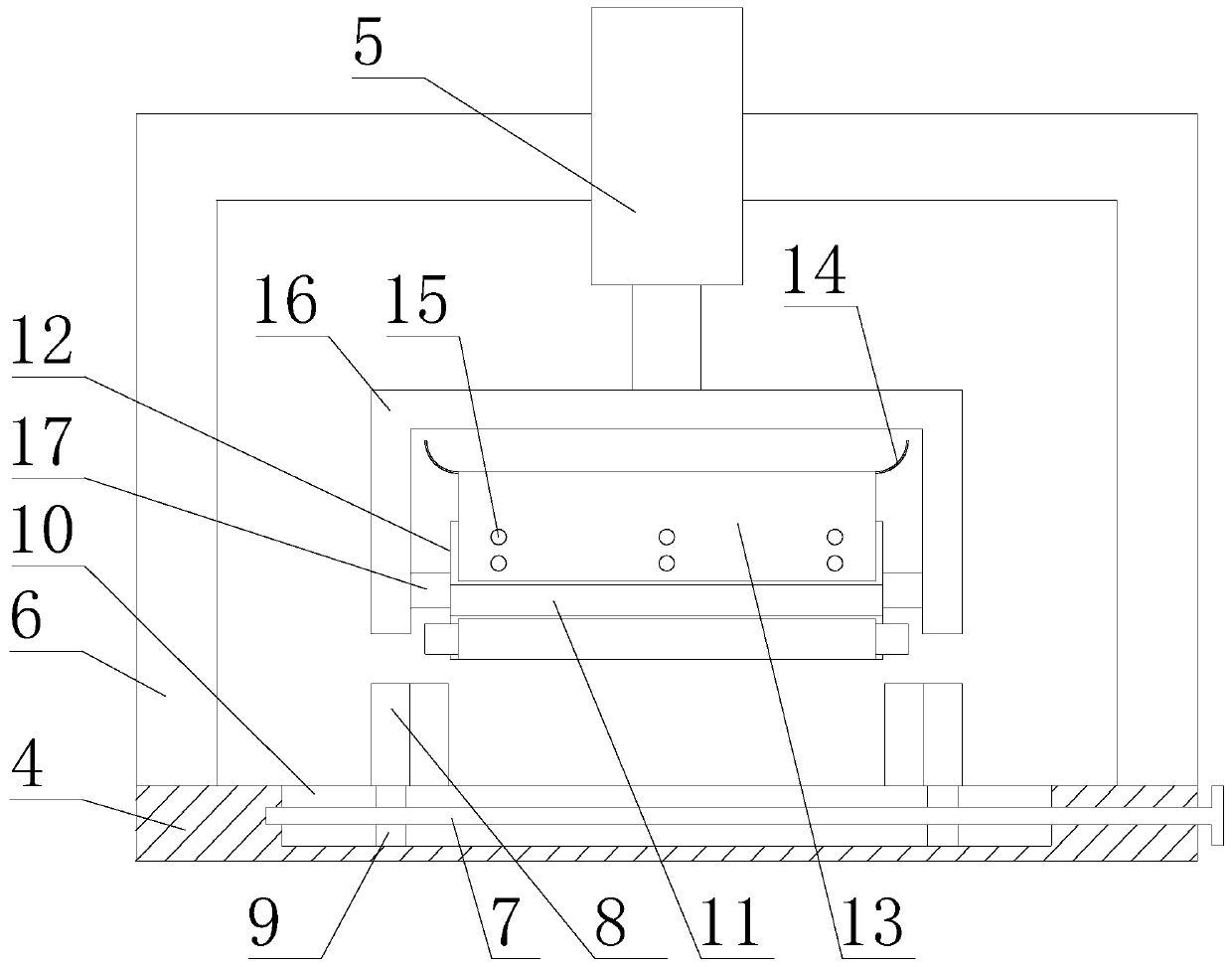

[0024] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to specific embodiments and drawings.

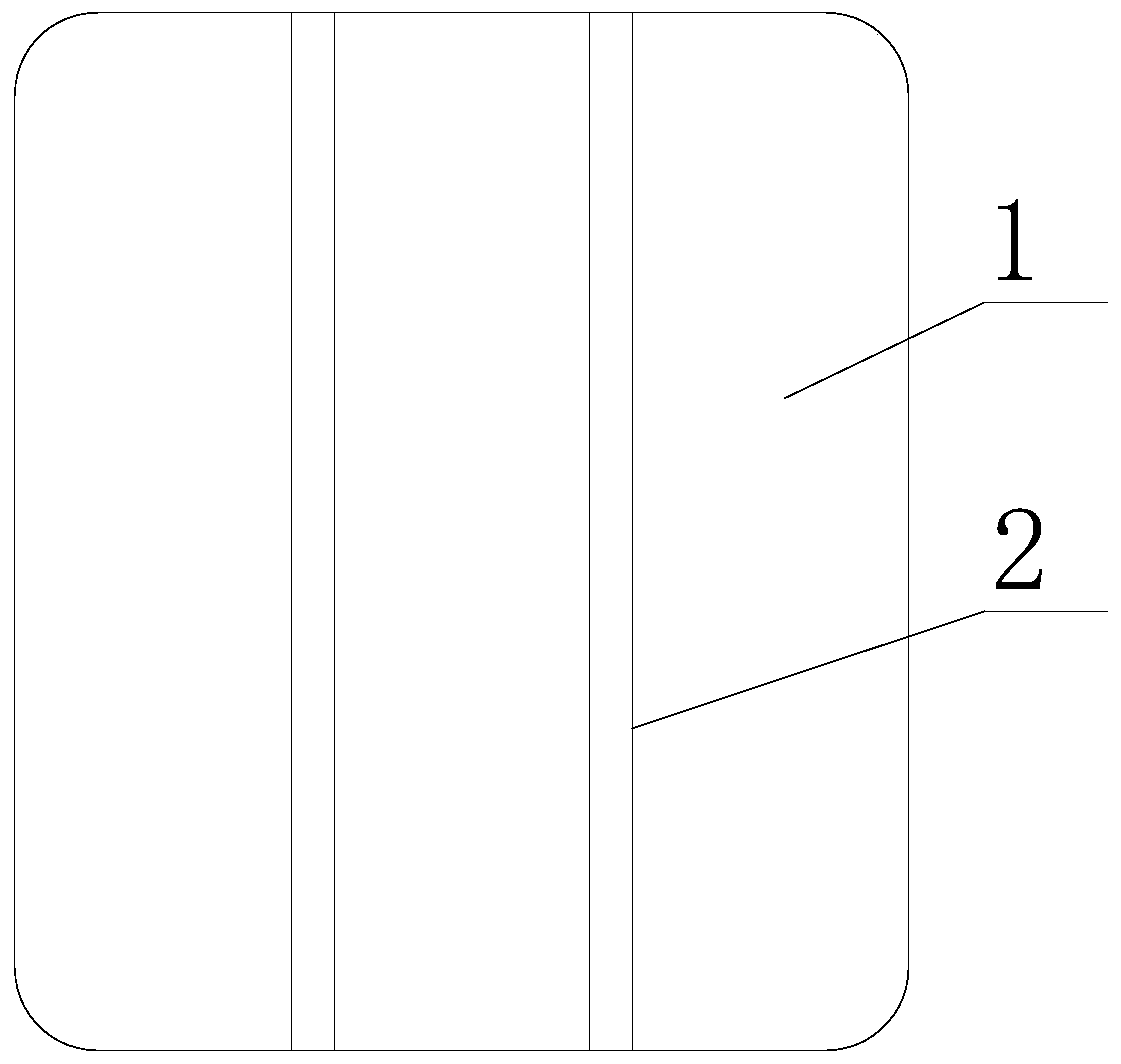

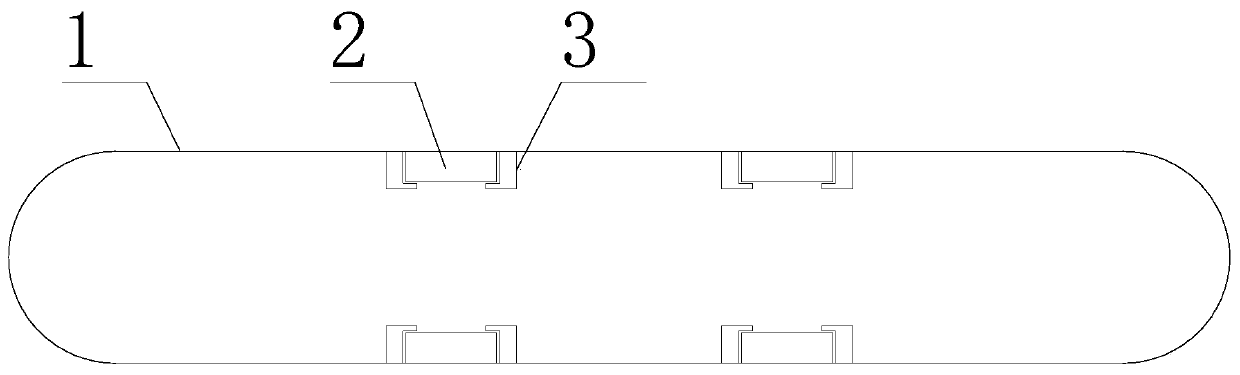

[0025] Based on the above objective, the first aspect of the present invention proposes an embodiment of a packaging bag, such as figure 1 As shown, it includes a bag body 1 and a self-adhesive tape 2. The inner wall of the bag body 1 is provided with several sets of partitions, and the partition includes two of the self-adhesive tapes 2, and the two self-adhesive tapes 2 are respectively arranged On different inner side walls of the bag body 1, the adhesive tape 2 is vertically arranged from the opening of the bag body 1 and extends to the bottom of the bag body 1, and the four corners of the bag body 1 are rounded.

[0026] With the self-adhesive tape 2 set in the bag body 1, when placing different types of items, the protective layer of the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com