Complexed shavings and complexed shaving board and manufacture methods thereof

A technology of particleboard and shavings, applied in the field of complexed particleboard and its manufacture, and complexed shavings, can solve the problems of being difficult to superimpose at the same time, difficult to realize the unity of functionalization and individualization, etc. Increase anti-corruption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of complexed radiata pine shavings, comprising

[0052] Step 1: Prepare an appropriate amount of radiata pine shavings;

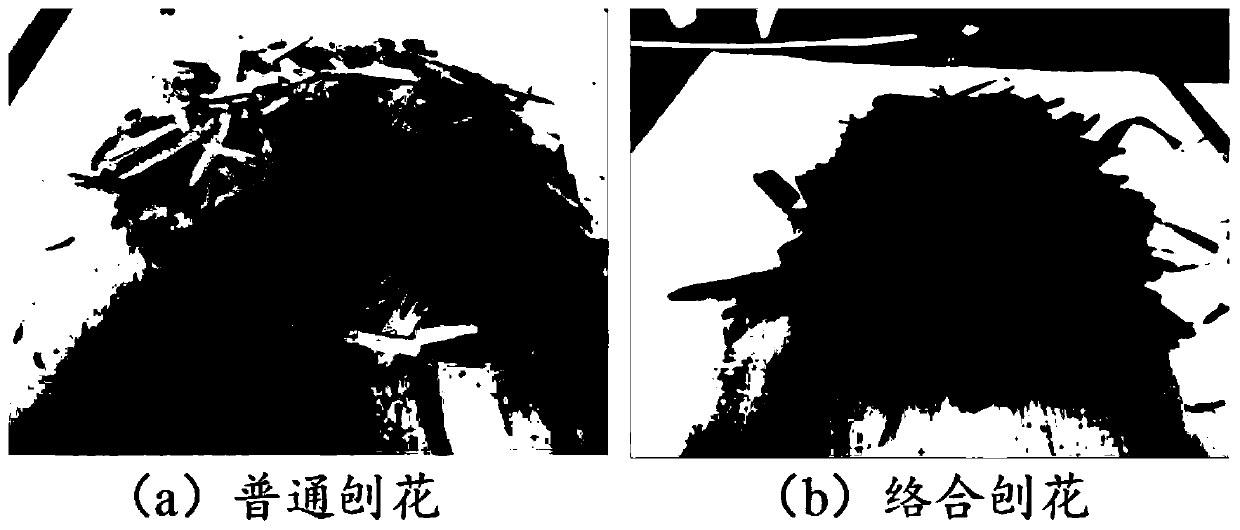

[0053] Saw radiata pine into 1000-2000mm wood sections, after peeling, use a planer to plan and form flat shavings; after drying, use airflow sorting to obtain flat shavings, such as figure 1 Shown in (a), belongs to prior art.

[0054] Step 2: introduce plant polyphenols into shavings to obtain polyphenol shavings;

[0055] 21) Dissolving tannin with an average molecular weight of 170 and a polymer of 1 in water, and stirring uniformly to form an aqueous tannin solution with a concentration of 1.0 g / L;

[0056] 22) Immerse the above-mentioned shavings in an aqueous tannin solution under normal pressure, the immersion time is 48 hours, and the immersion temperature is 25°C;

[0057] 23) Dry the shavings impregnated with the aqueous tannin solution.

[0058] Step 3: introducing metal salt into polyphenol shavings to obtain pol...

Embodiment 2

[0066] A preparation method of complexed eucalyptus shavings, comprising

[0067] Step 1: Prepare an appropriate amount of shavings;

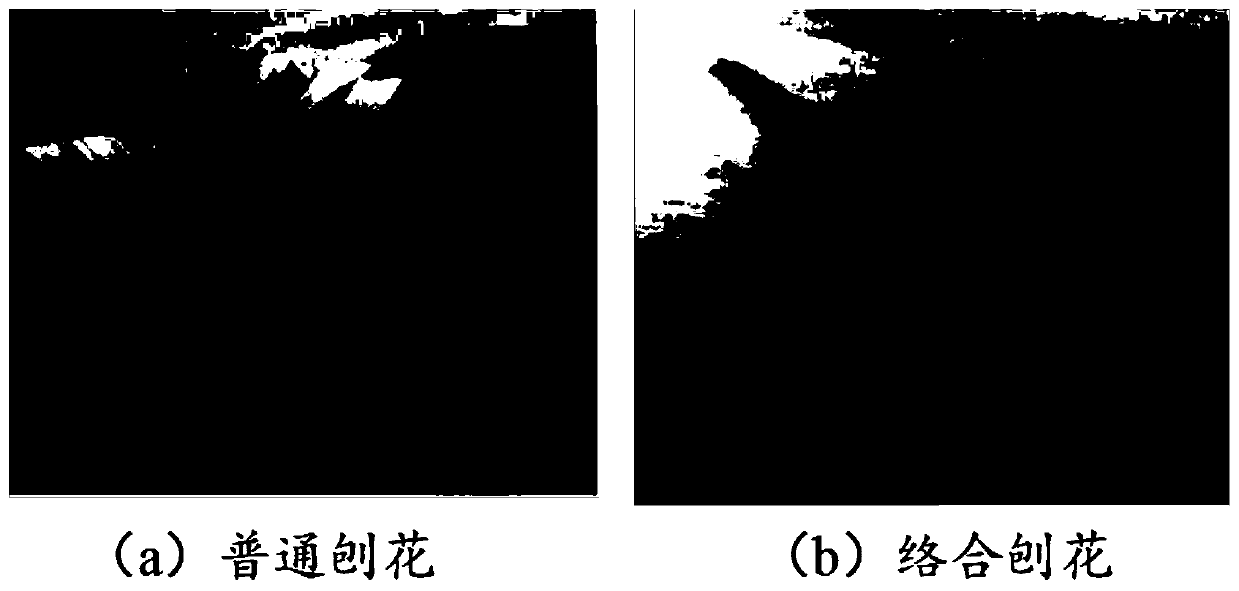

[0068] Saw the eucalyptus into 1300mm wood sections, use a rotary cutter to cut into veneers of 1.0mm, form large regular shavings after cutting, and make eucalyptus shavings after drying, such as image 3 (a) shown.

[0069] Step 2: Introduce black wattle bark extract (polyflavanoid plant polyphenols) into shavings to obtain polyphenol shavings;

[0070] 21) Dissolving black wattle bark extract in water and stirring evenly to form an aqueous solution of black wattle bark extract with a concentration of 1 g / L;

[0071] 22) Immerse the above shavings in the black wattle bark extract solution, the immersion pressure is 0.4MPa, the immersion time is 10min, and the immersion temperature is 20°C;

[0072] 23) Dry the shavings impregnated with the aqueous solution of black wattle bark extract.

[0073] Step 3: introducing metal salt into polyphen...

Embodiment 3

[0081] A preparation method for complex poplar wood shavings, comprising

[0082] Step 1: Prepare appropriate amount of poplar wood shavings;

[0083] Poplar or poplar branches are cut into wood chips with a chipper, and then planed into rod-shaped shavings with a double-drum planer, which belongs to the prior art;

[0084] Step 2: import bayberry extract (polygallate plant polyphenol) into shavings to obtain polyphenol shavings;

[0085] 21) Dissolving red bayberry extract in water and stirring evenly to form an aqueous solution of red bayberry extract with a concentration of 3.0 g / L;

[0086] 22) Immerse the above-mentioned shavings in the plant polyphenol aqueous solution under normal pressure, the immersion time is 8 hours, and the immersion temperature is 25°C;

[0087] 23) Drying the shavings impregnated with the aqueous solution of bayberry extract.

[0088] Step 3: introducing metal salt into the shavings of bayberry extract to obtain metal salt shavings of bayberry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com