A rotary hanging paint spray rack for the interior of a chemical plant

A technology of rotating and spraying racks, applied in the field of spraying racks, which can solve the problems of inability to spray paint on pendants of different sizes, poor applicability of spraying racks, poor spraying effect, etc., to achieve the effect of improving painting efficiency, flexible use, and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

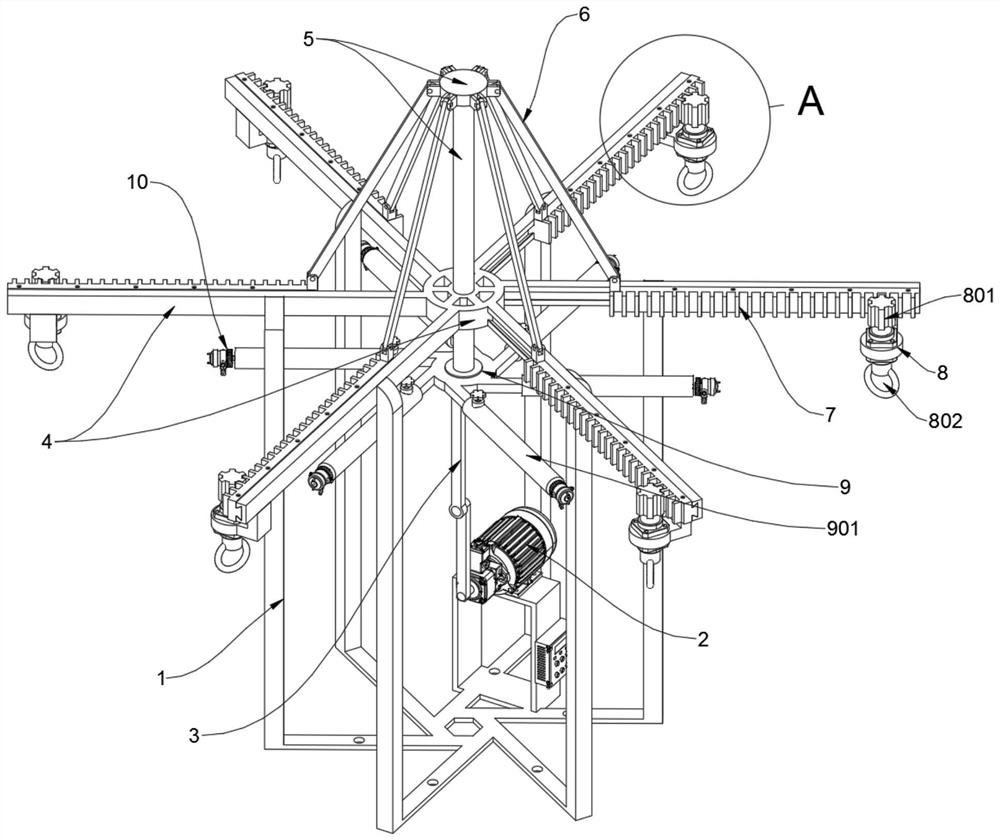

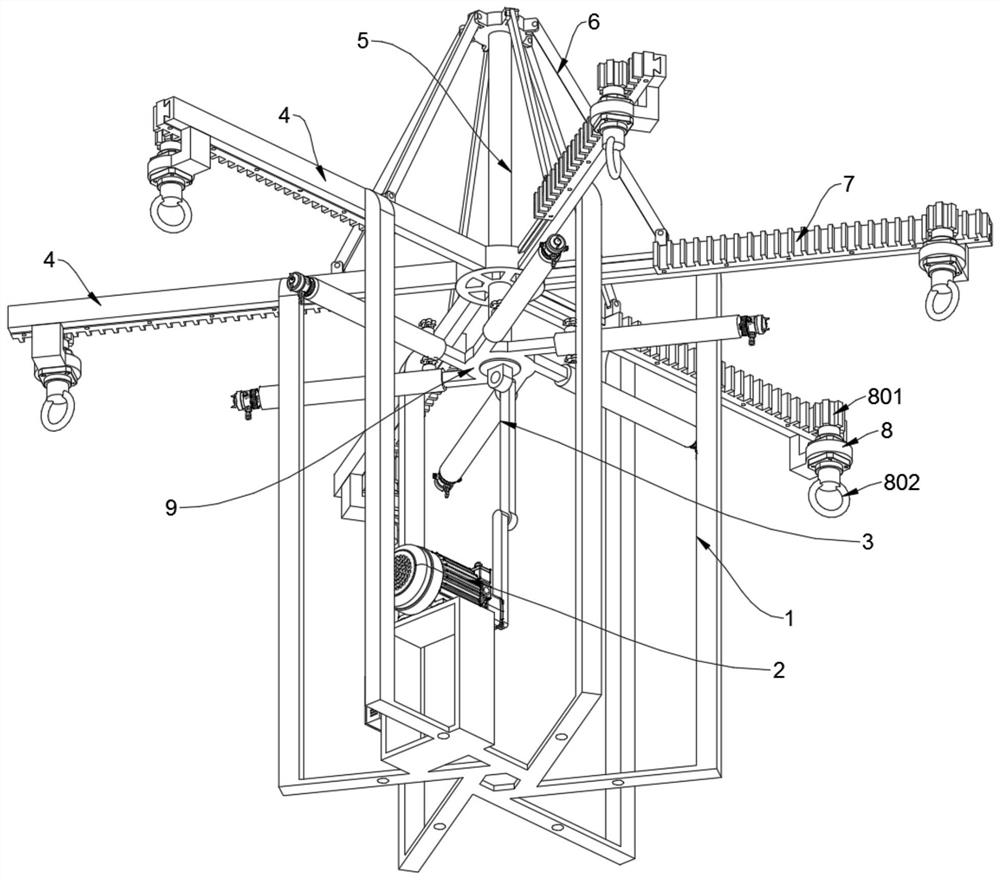

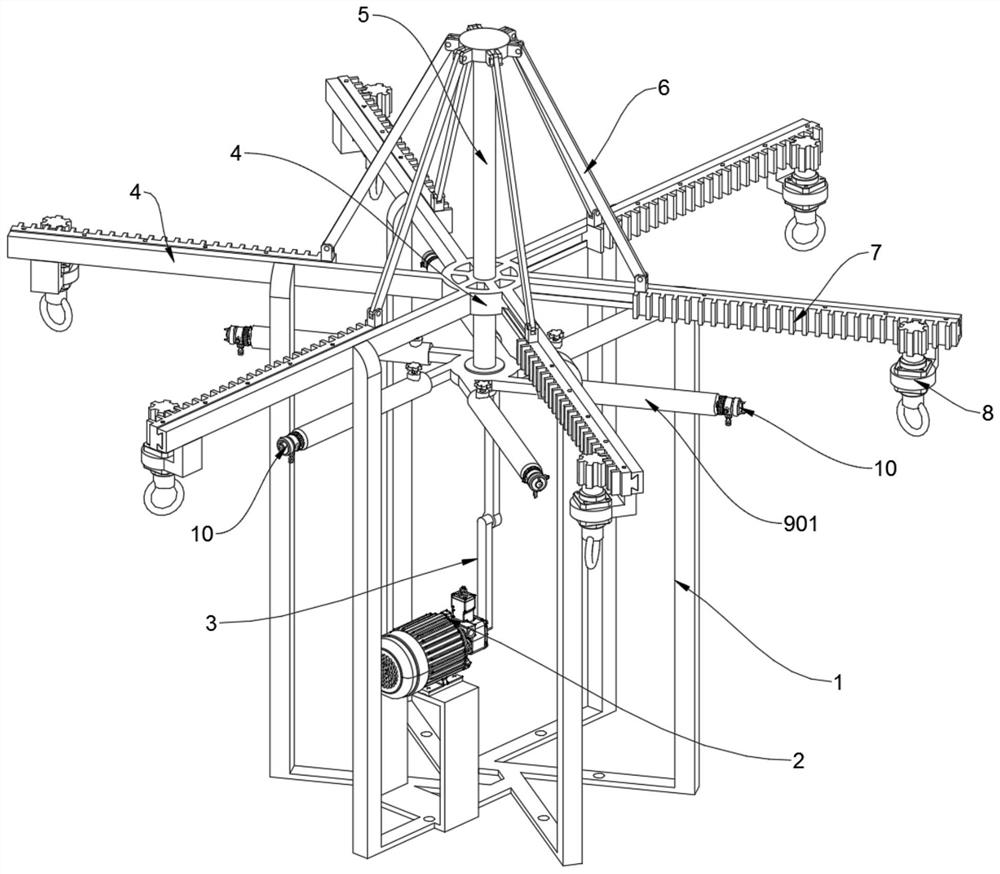

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides a rotary hanging paint spraying frame used inside a chemical plant, which includes a six-column support 1 and a lifting frame 9, the top of the six-column support 1 is welded with a mounting frame 4, and the bottom of the six-column support is supported on a hexagonal base. A motor 2 is installed; the mounting frame 4 is composed of a central mounting ring and six track plates supported on the central mounting ring in an annular array; a slide shaft 5 is supported and welded at the center of the lifting frame 9, The sliding shaft 5 runs through the center of the mounting bracket 4 .

[0035] Wherein, a rack plate 7 is slidably inserted in the track grooves surrounding the track plate at six positions of the mounting frame 4, and a bearing seat 8 is welded and installed on the outer head end positions of the six track plates. The six surrounding track plates provide convenience for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com