Automatic gluing jig for automobile side skirt inner plate

A car side and gluing technology, which is applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve the problems of low efficiency of manual gluing, inaccurate gluing position, and many staffings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

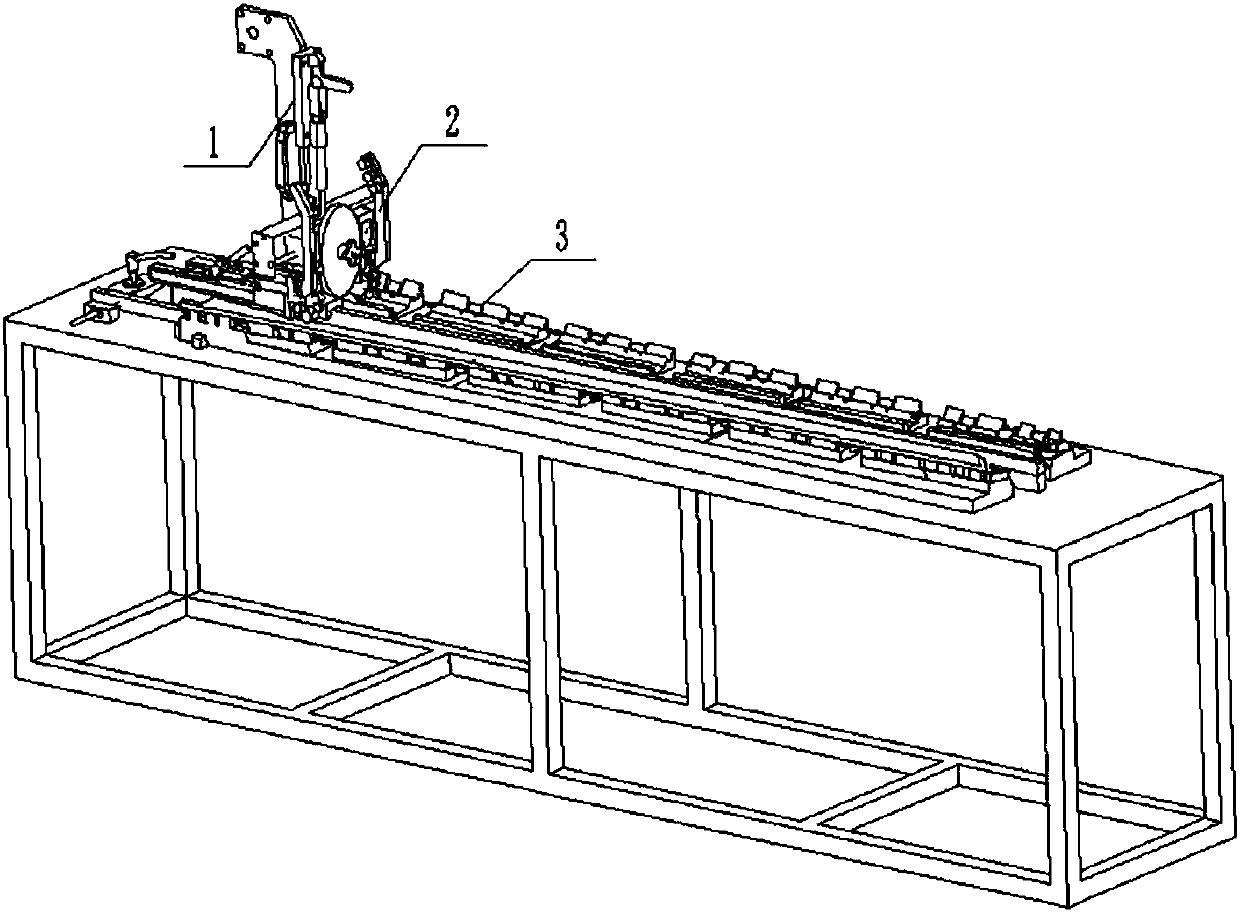

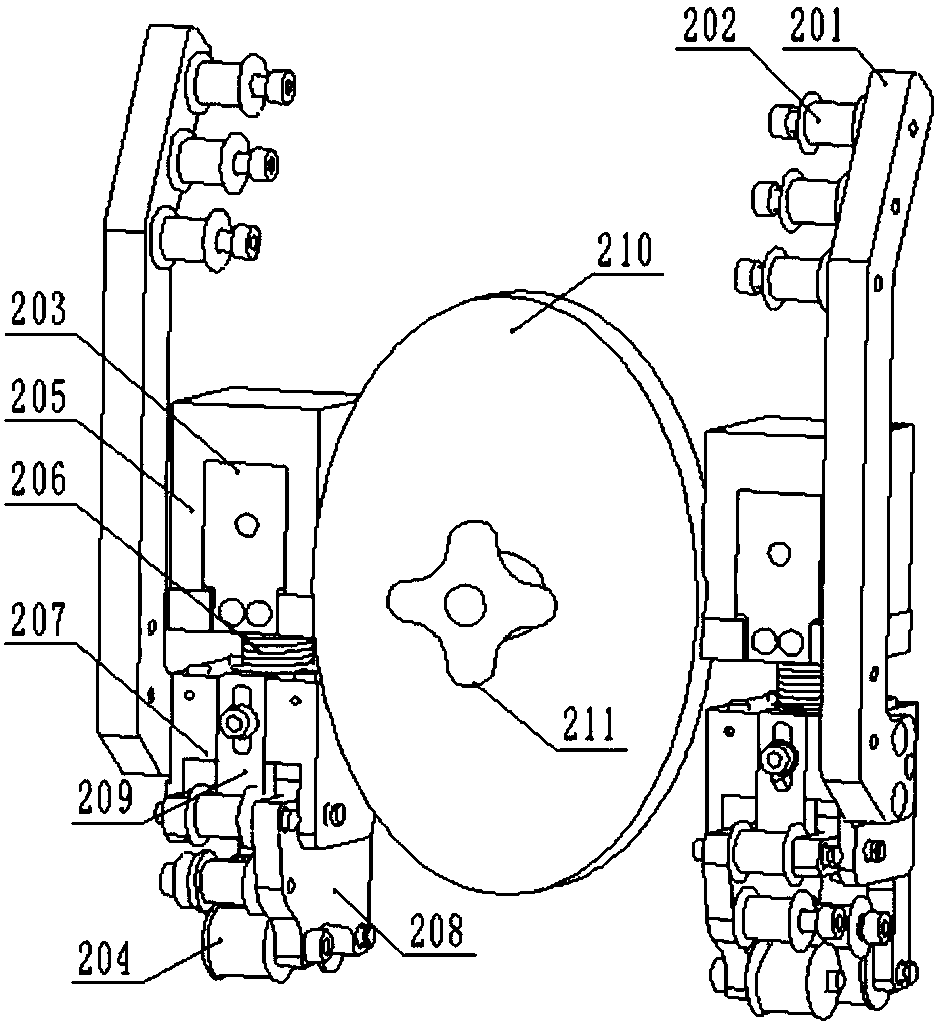

[0010] 1. Refer to figure 1 , 2, 3, 4 In the automatic gluing fixture for the inner panel of the side skirt of the automobile provided by the present invention, the slide block III112 in the transmission mechanism 1 is connected with the gluing upper block 205 in the gluing mechanism 2 by bolts, and the The slide rail II108 is connected with the slide block IV312 in the supporting mechanism 3 by bolts.

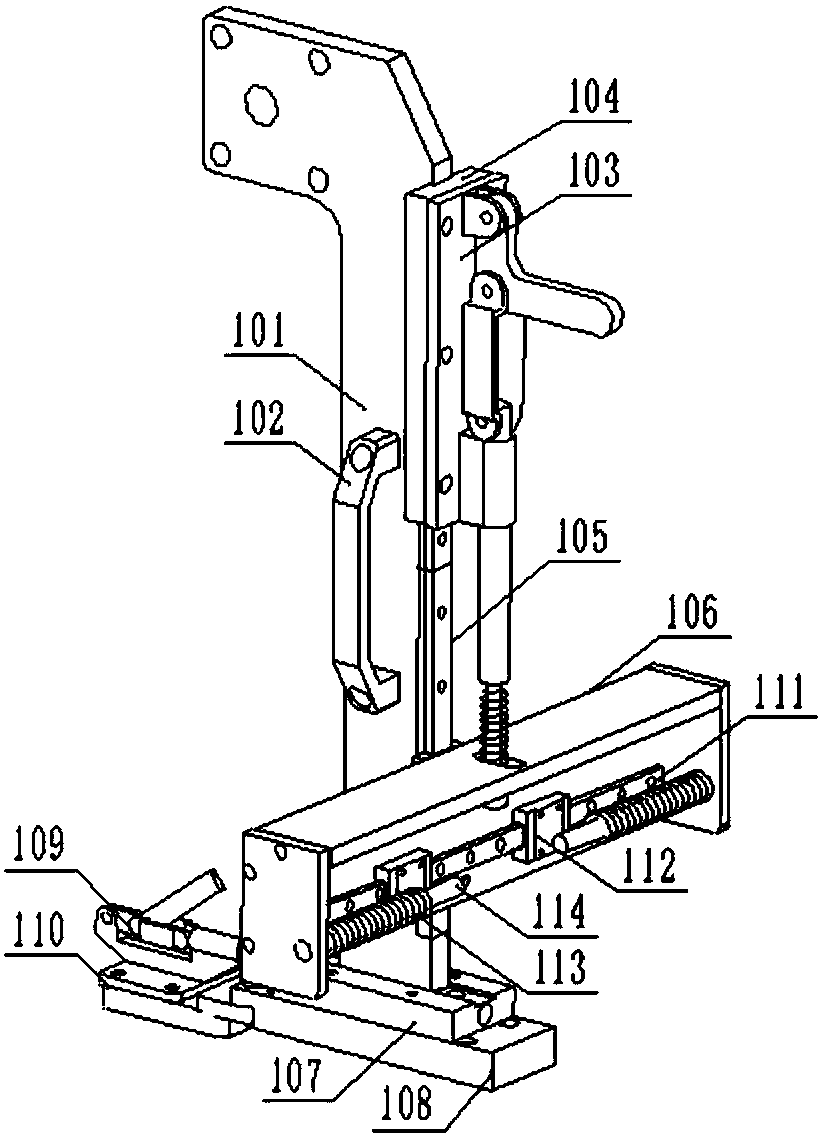

[0011] 2. If figure 2 As shown, the rubber disc bracket 101 is connected to the handle 102 by bolts, the backing plate 103 is connected to the slider I104 by bolts, the slide rail I105 is connected to the rubber disc bracket 101 by bolts, the slider II107 is connected to the slide rail II108 by bolts, and the slide rail II108 is connected to the fixed plate 110 by bolts, the lower clamp 109 is connected to the fixed plate 110 by bolts, the slide rail III111 is connected to the square box 106 by bolts, the slider III112 is connected to the slide rail III111 by bolts, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com