TBM disk-shaped hobbing cutter additionally provided with reinforcement ribs on side face of cutter ring

A technology of disc-shaped hobs and reinforcing ribs, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of cutter ring wear, low strength, and cutter ring cracking, so as to reduce the eccentric wear of the cutter ring and reduce wear and damage, reduce the effect of the knife circle cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

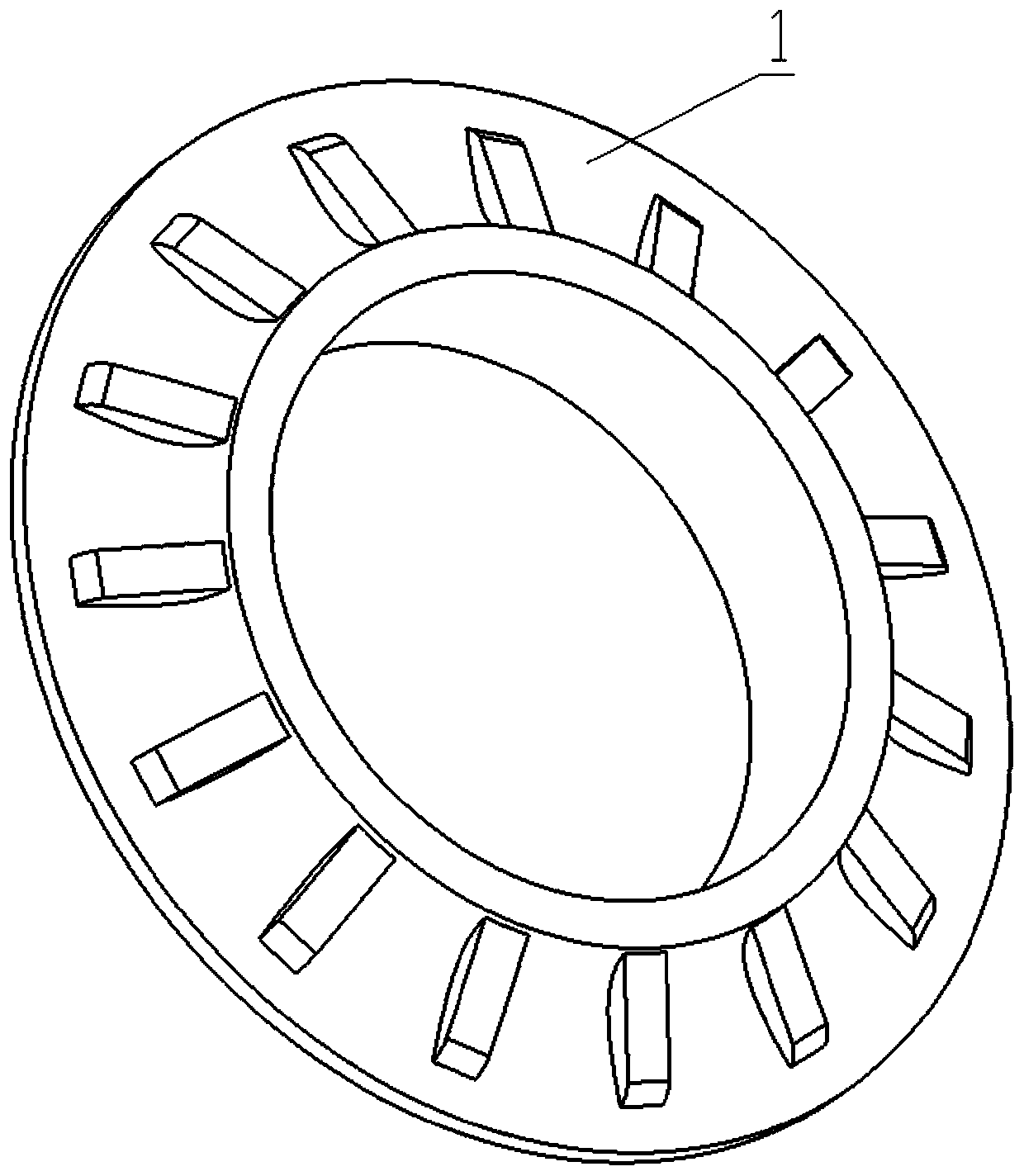

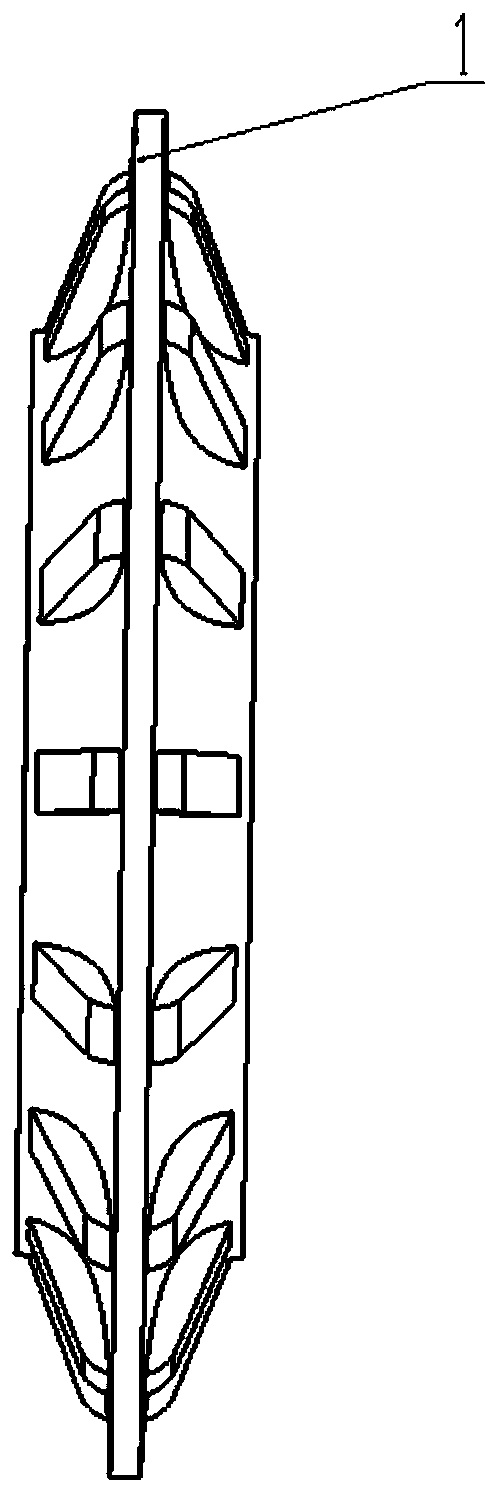

[0031] Please refer to figure 1 , this embodiment provides a TBM disc hob with reinforcing ribs added to the side of the cutter ring 1, which includes: a cutter ring 1, a retaining ring 2, a cutter body 3, a bearing end cover 4, an isolation ring 5, a shaft 6, and a bearing 7 and a sealing ring 8; the side of the knife ring 1 is provided with a plurality of reinforcing ribs, the knife ring 1 is arranged on the outer peripheral side of the knife body 3, the retaining ring 2 positions the knife ring 1 at the position of the knife body 3, the bearing 7 is assembled on the shaft 6 and Located inside the cutter body 3, the bearing end cover 4 seals the bearing 7 inside, the spacer ring 5 separates the bearing 7, and the sealing ring 8 seals the gap between the bearing end cover 4 and the cutter body 3; the cutter ring 1 adds a reinforcing rib structure Realize the improvement of the strength of the cutter ring 1, and at the same time ensure that the hob can rotate effectively durin...

no. 2 example

[0035] The second embodiment is partly the same as the first embodiment, except that the reinforcing ribs of the cutter ring 1 are arranged in a distributed manner.

[0036] Please refer to figure 1 , Figure 4 and Figure 5 , this embodiment provides a TBM disc hob with reinforcing ribs added to the side of the cutter ring 1, which includes: a cutter ring 1, a retaining ring 2, a cutter body 3, a bearing end cover 4, an isolation ring 5, a shaft 6, and a bearing 7 and a sealing ring 8; the side of the knife ring 1 is provided with a plurality of reinforcing ribs, the knife ring 1 is arranged on the outer peripheral side of the knife body 3, the retaining ring 2 positions the knife ring 1 at the position of the knife body 3, the bearing 7 is assembled on the shaft 6 and Located inside the cutter body 3, the bearing end cover 4 seals the bearing 7 inside, the spacer ring 5 separates the bearing 7, and the sealing ring 8 seals the gap between the bearing end cover 4 and the cu...

no. 3 example

[0040] The third embodiment is partly the same as the first embodiment, except that the reinforcing ribs of the cutter ring 1 are arranged in a distributed manner.

[0041] Please refer to figure 1 , Figure 6 and Figure 7 , this embodiment provides a TBM disc hob with reinforcing ribs added to the side of the cutter ring 1, which includes: a cutter ring 1, a retaining ring 2, a cutter body 3, a bearing end cover 4, an isolation ring 5, a shaft 6, and a bearing 7 and a sealing ring 8; the side of the knife ring 1 is provided with a plurality of reinforcing ribs, the knife ring 1 is arranged on the outer peripheral side of the knife body 3, the retaining ring 2 positions the knife ring 1 at the position of the knife body 3, the bearing 7 is assembled on the shaft 6 and Located inside the cutter body 3, the bearing end cover 4 seals the bearing 7 inside, the spacer ring 5 separates the bearing 7, and the sealing ring 8 seals the gap between the bearing end cover 4 and the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com