Novel flange type tubing pup joint used for oil field

A technology of using flange type and oil pipe, applied in drilling pipe, casing, drilling equipment, etc., can solve the problems of poor versatility and unsatisfactory use effect, and achieve the effect of wide application range, flexible use and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

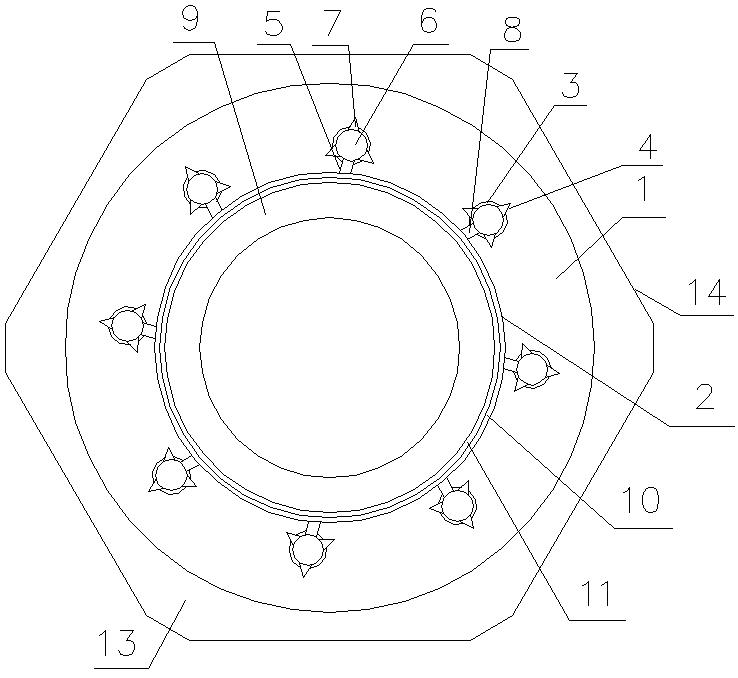

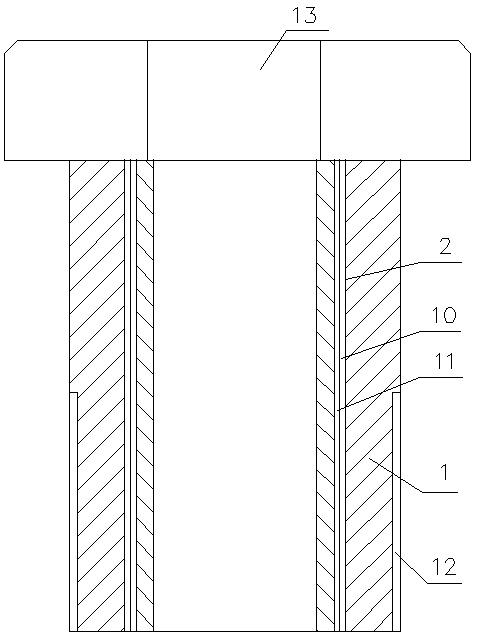

[0017] A new type of flanged tubing sub-joint for oil fields, which consists of: a tubing sub-joint 1, the tubing sub-joint has an oil passage hole 2, and a group of insertion fixing holes 3 are opened around the circumference of the tubing sub-joint, the There are 3-8 plug-in fixing holes described above, and the described plug-in fixing holes connect three triangular slots 4 with an included angle of 120︒ around the circumference, and the described plug-in fixing holes connect to the positioning card slot 5. Insert the fixed rod 6 tightly into the plug-in fixing hole, and the fixed rod connects three triangular insert rods 7 with an included angle of 120︒ around the circumference, and the triangular insert rod is tightly fitted and inserted into the triangular slot , the fixed rod is fixedly connected to the positioning clamp 8, the positioning clamp is fixedly connected to the bushing sleeve 9, the inner diameter of the bushing sleeve is 4 minutes to 2 inches, and the bushin...

Embodiment 2

[0021] In the novel flanged tubing pup joint for oil fields described in Example 1, the inner diameter of the bushing is 4 inches or 6 inches or 1 inch or 1.2 inches or 1.5 inches or 2 inches.

[0022] working principle:

[0023] Choose 4 points or 6 inches or 1 inch or 1.2 inches or 1.5 inches or 2 inches bushing sleeve according to the needs, insert the fixed rod tightly into the plug fixing hole, the triangular insert rod tightly fit into the triangular slot, and position the card The plate is tightly fitted and inserted into the positioning card slot to fix the bushing sleeve, and a sealing ferrule is installed between the bushing sleeve and the oil hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com