Contact piece riveting tool and riveting method

A technology for riveting tools and contacts, which is applied in the direction of manufacturing tools, connections, electrical components, etc., can solve the problems of affecting the use cost of devices, reducing work efficiency, and scrapping contacts, so as to improve riveting quality, improve work efficiency, and reduce circulation when the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

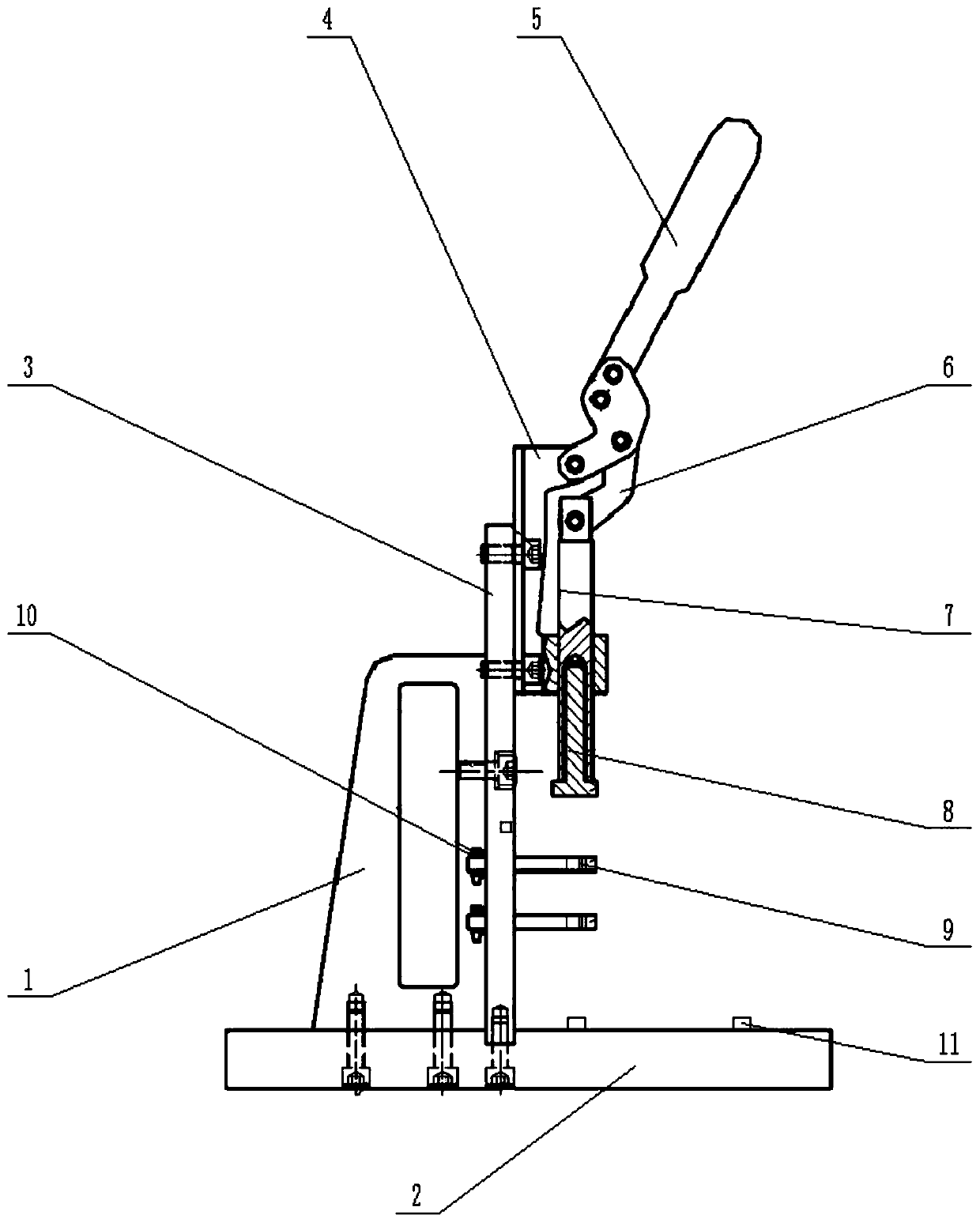

[0032] A contact riveting tool, including a riveting module and a base; such as figure 1 As shown, the pressure riveting module includes a handle 1, a horizontal fixing plate 2 and a vertical fixing plate 3, the handle 1 is fixed to the horizontal fixing plate 2 by bolts, and the vertical fixing plate 3 is fixed to the handle 1 by bolts. side. The upper part of the vertical fixed plate 3 is equipped with a fixture, and the clamp includes a mounting seat 4, a handle 5, a linkage rod 6 and a lower pressure rod 7, and the mounting seat 4 is fixed on the vertical fixed plate 3 by bolts. One end of the handle 5 is hinged to the upper part of the mounting base 4, and the other end is in transmission connection with the lower pressing rod 7 through the linkage rod 6. The lower pressing rod 7 is placed in the limit sleeve of the mounting base 4, and the lower pressing rod 7 The front end is provided with a detachable chuck 8; the bottom of the vertical fixing plate 3 has a hole, and ...

Embodiment 2

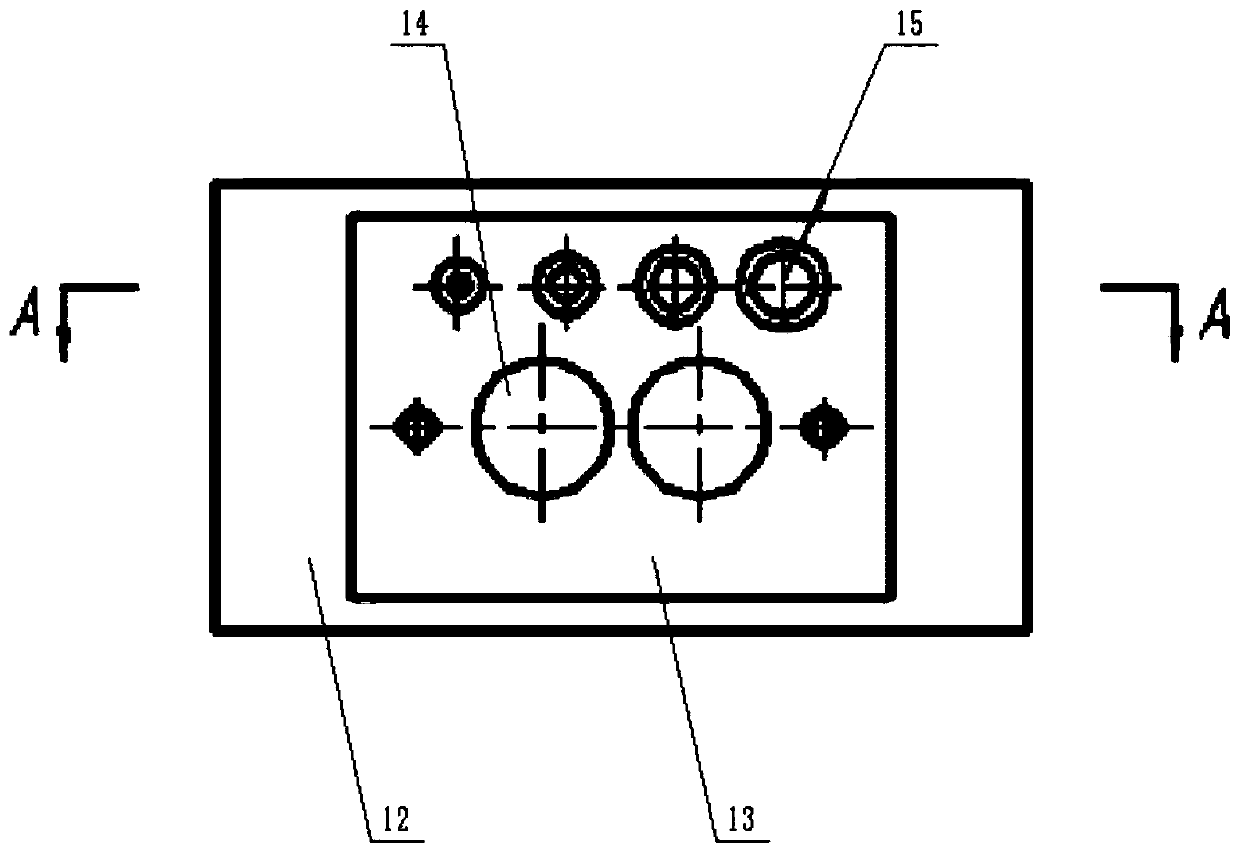

[0037] Such as Figure 6As shown, on the basis of Embodiment 1, positioning and fixing holes 24 are provided on the first base plate of the base, and positioning and fixing holes 24 are provided on the horizontal fixing plate of the pressure riveting module corresponding to the positions of different positioning protrusions and mounting holes on the base. The base can be fixed on the horizontal fixing plate through the bolt, and the positioning and fixing holes at different positions up and down are used to cooperate to ensure that the components to be riveted at different positions on the base correspond to the upper and lower sides of the chuck of the fixture.

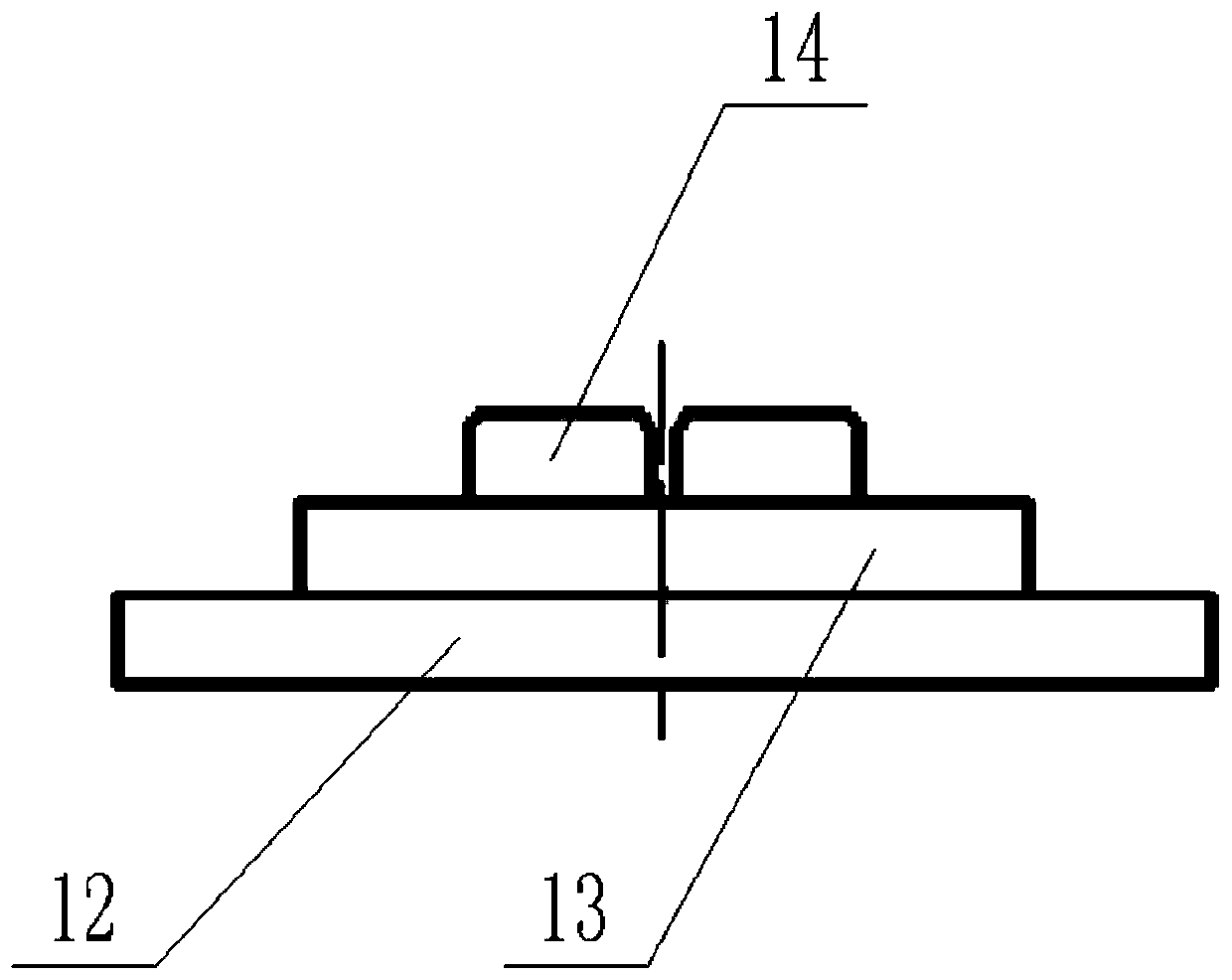

[0038] Enables contact riveting to socket body such as figure 1 and Figure 7 As shown, first put the parts to be riveted into the riveting positioning tube 20, put the SMC protective sleeve 21, a certain type of contact point 22 and the socket body 23 into the riveting positioning tube 20 from top to bottom, and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com