Hydroxyapatite functionalized monolithic column prepared by in situ mineralization method

A hydroxyapatite, in-situ mineralization technology, applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve problems such as uneven distribution of HAP and decreased column permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

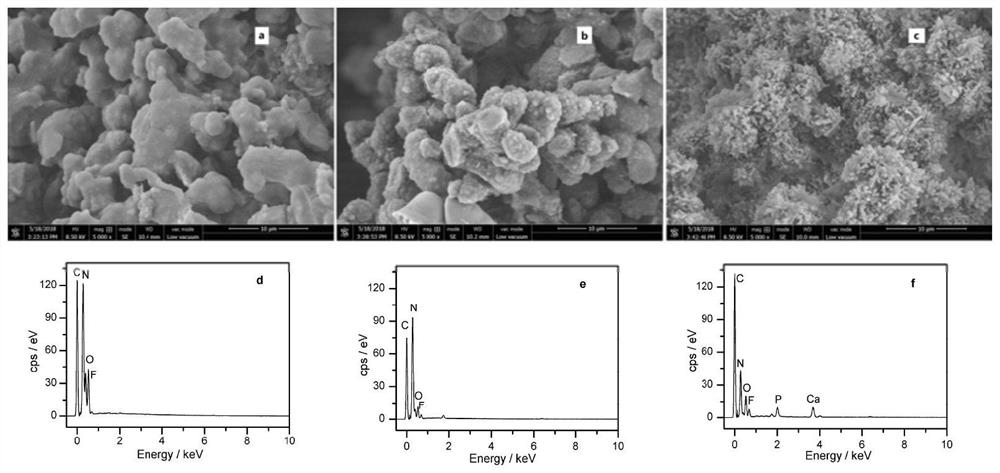

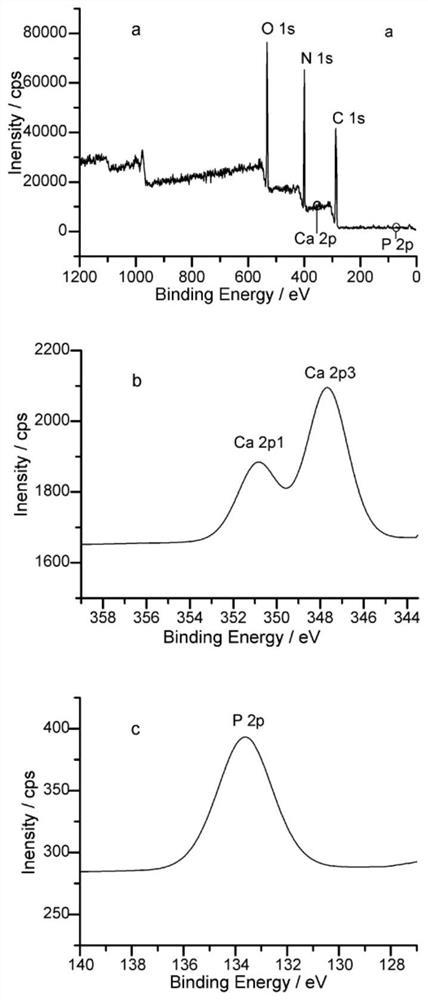

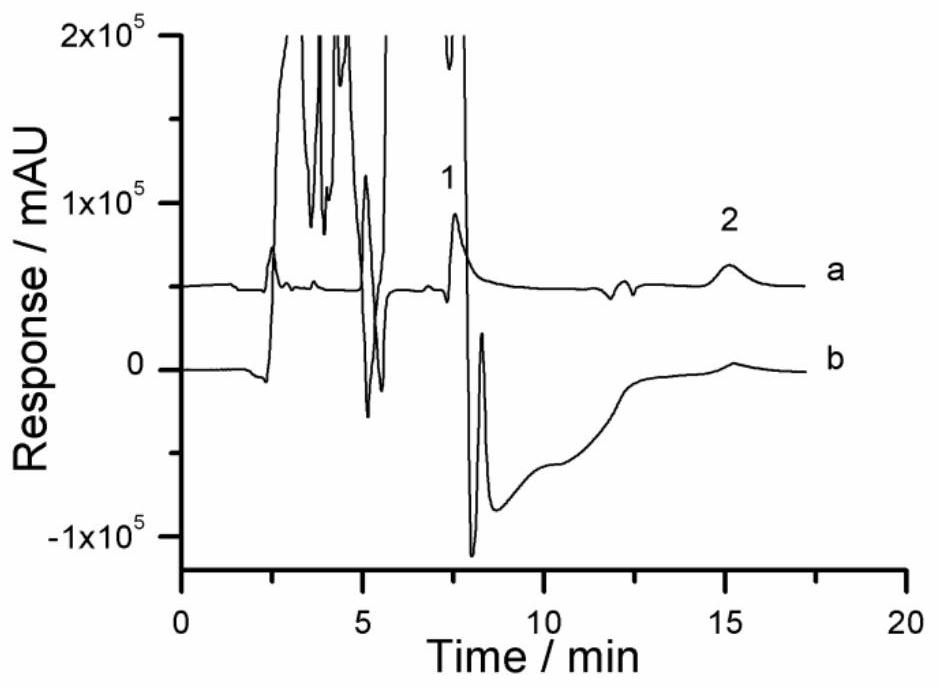

Image

Examples

preparation example Construction

[0028] (1) Preparation of Monolithic Column: chromatographically pure methanol ATC PTFE washed for half an hour, and then placed in an oven at 60 ℃ drying; a concentration of 1g / mL aqueous urea solution, mass fraction of 37% formaldehyde solution and 0.1mol / L hydrochloric acid solution of 4: 5: 1 by volume mixed ratio of charged Teflon tube previously washed in a reaction 10 to 120 minutes to obtain urea-formaldehyde resin at 45-65 deg.] C in a water bath Monolithic column (in table 1 for some specific examples).

[0029] Table 1 Preparation Conditions urea-formaldehyde resin Monolithic Column

[0030] Serial number Condefficient temperature (° C) Reaction time (min) a 45 60 b 45 120 c 55 10 d 55 30 e 55 60 f 55 120 g 65 10 h 65 30

[0031] (2) Coating of dopamine: water flushed through the UF support micro-infusion pump monolith one hour to remove unreacted substances within the column; the same time, taking 5mL 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com