Drive device for a movable tappet

A technology of driving device and translational movement, which is applied in the direction of transmission device, electromechanical device, electric component, etc., to achieve the effect of maintenance-free and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

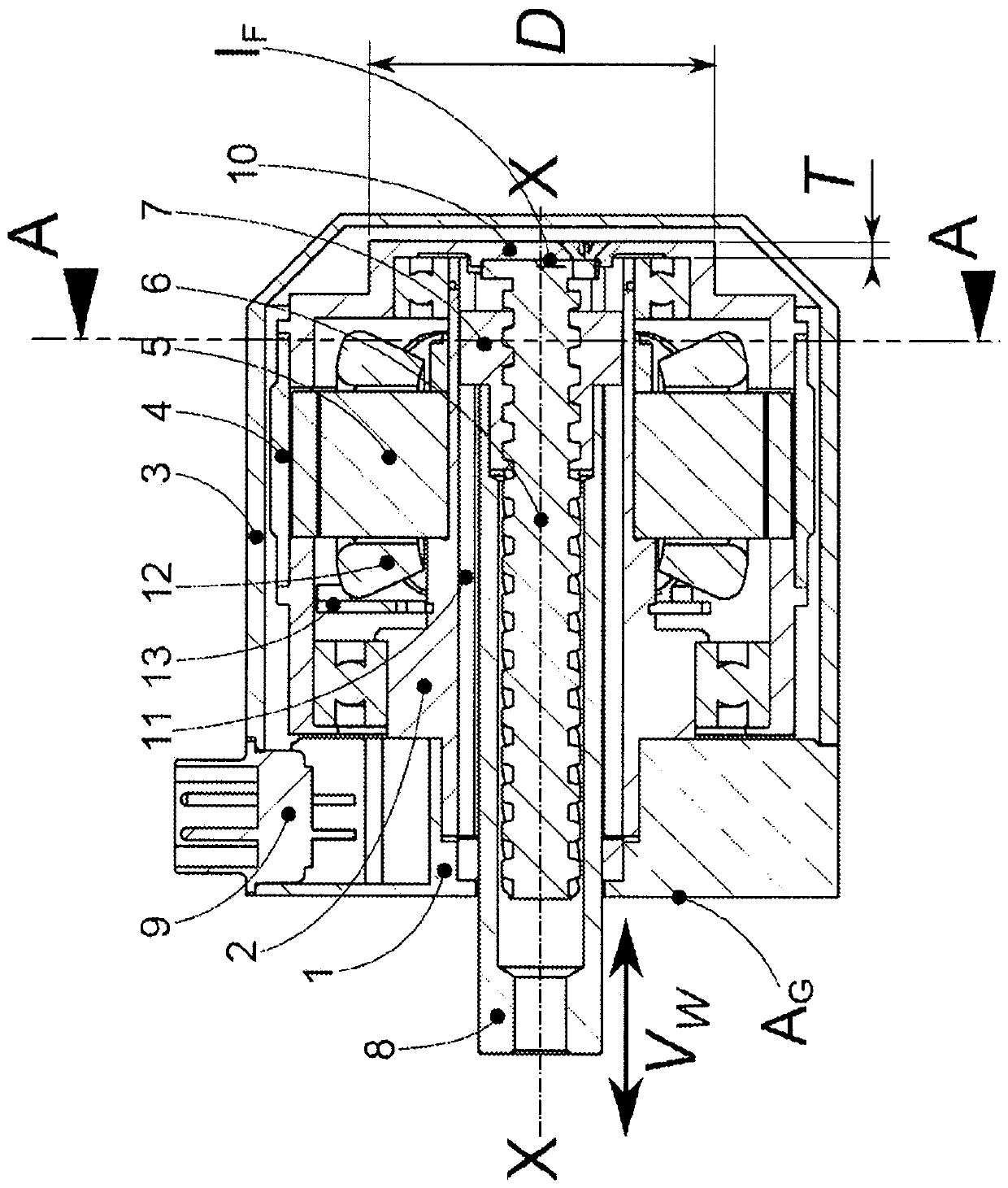

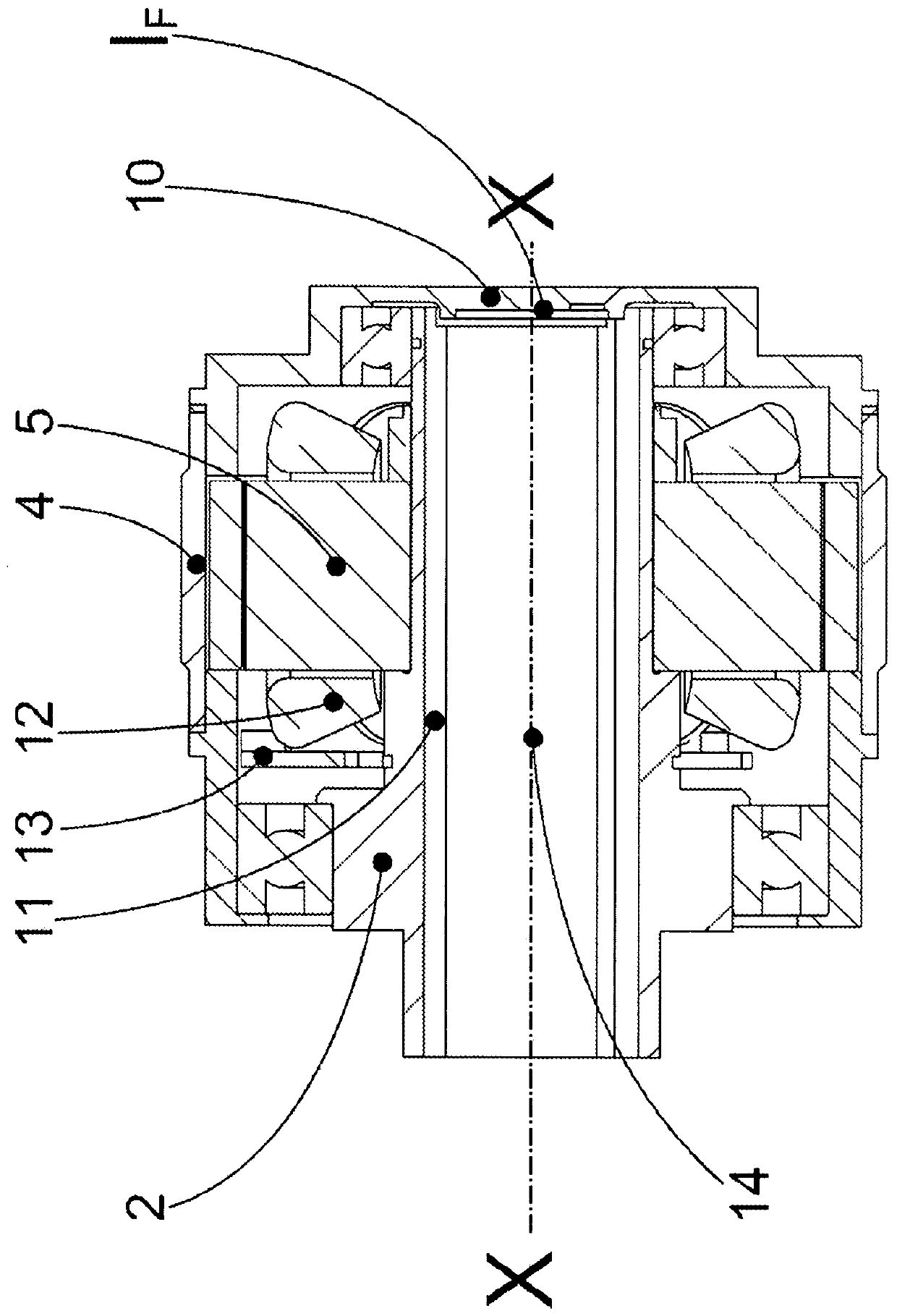

[0071] exist figure 1 A drive device (1') for generating a translational movement of a movable tappet (8) by means of an electromagnetic rotary machine is schematically shown in .

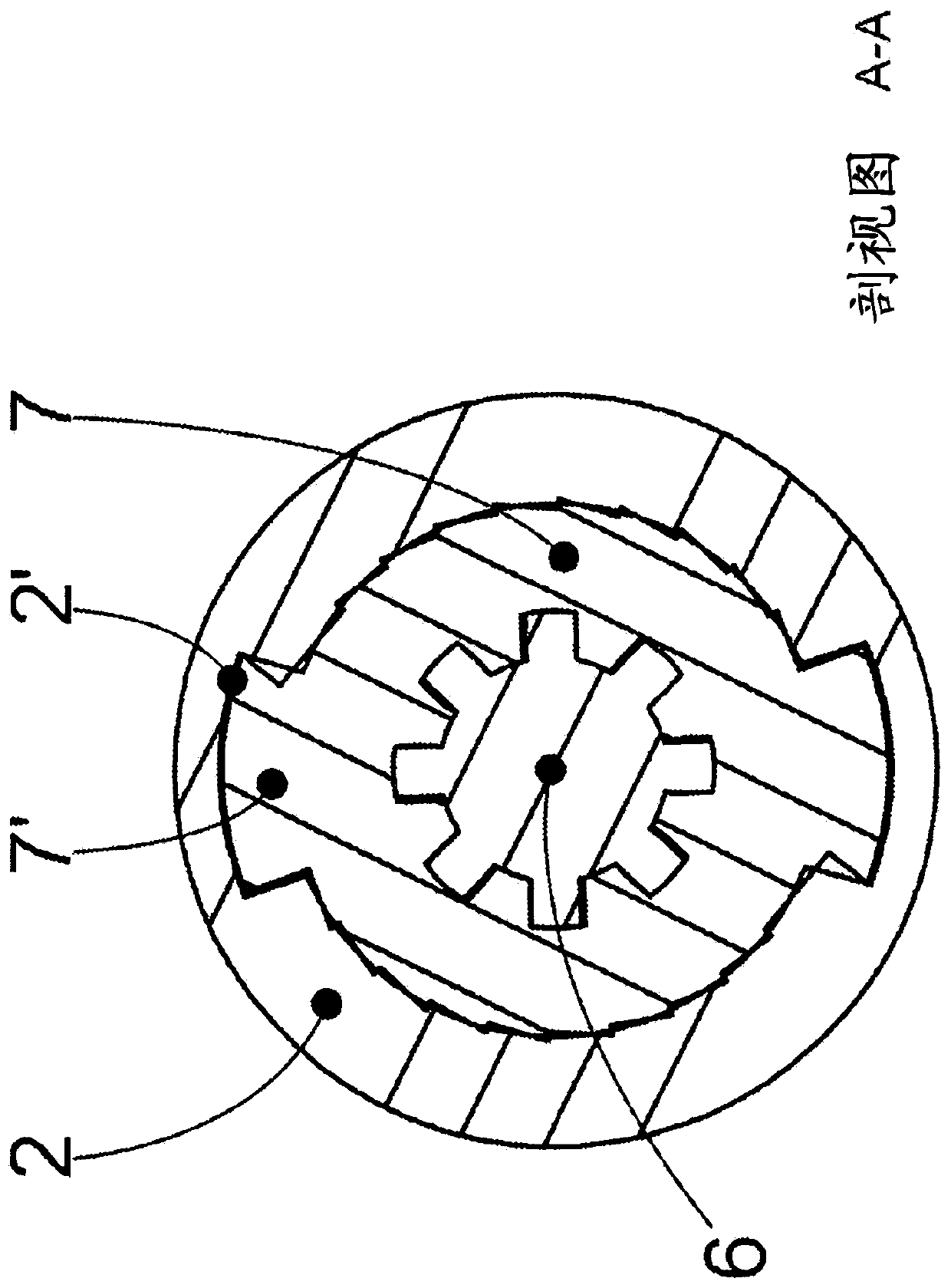

[0072] The drive (1') can comprise, for example, the following components: housing flange (1) with stator tube or stator sleeve (2), protective cover (3), rotor (4), provided with winding (12) The stator (5) or the stator plate group (5), the screw (6) together with the nut (7) and the tappet (8) and the joint (9) for the control and power electronics, the winding and the sensor system (13) Being connected.

[0073] The stator (5) is arranged coaxially with respect to the rotor (4) and comprises at least one pair of moving threads (6, 7) coaxially integrated therein, said pair of moving threads comprising a non-rotatably coupled rotor (4) connected screw (6) and a nut (7) guided linearly in a torsionally fixed manner in the stator sleeve (2), which is preferably rigidly coupled to a tubular tapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com