A battery heating film and a battery box water ingress detection device

A detection device and battery heating technology, applied in secondary battery testing, secondary battery, secondary battery repair/maintenance, etc., can solve problems such as stress breaking, short circuit, high vibration breaking probability of wires, etc., to prevent wear and tear problems, ensuring service life, and simplifying the effect of wiring harness layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

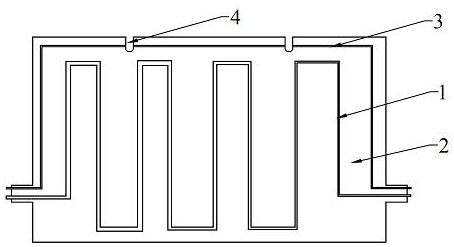

[0069] Such as figure 1 As shown, the battery heating film in Example 1 is rectangular, and the battery heating film includes a heating wire 1 and an insulating coating layer 2 arranged outside the heating wire 1, and also includes a detection wire 3 arranged in the insulating coating layer 2, and the battery The heating film is provided with two notches 4 for cutting off the detection wire, and the positive and negative terminals of the heating wire 1 and the detection wire 3 are arranged on both sides of the battery heating film.

Embodiment 2

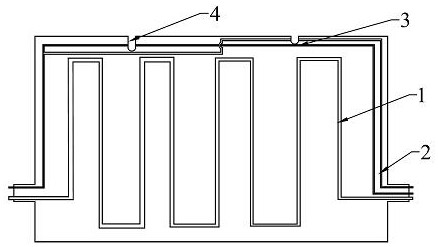

[0071] Such as figure 2 As shown, Embodiment 2 is based on Embodiment 1. In Embodiment 2, the two detection wires 3 are arranged on one side of the heating wire 1 in the battery heating film, and the gaps 4 of the two heating wires are located on the same side of the battery heating film.

Embodiment 3

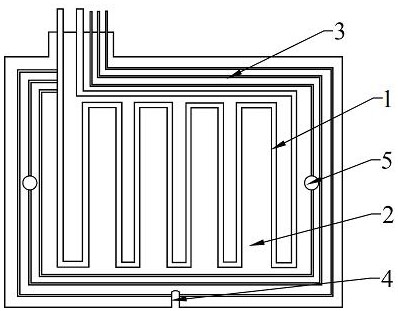

[0073] Such as Figure 3-4 As shown, embodiment 3 is based on embodiment 1, the difference is that in embodiment 3, three open-loop detection wires 3 arranged in sequence from outside to inside are provided, and the leading ends of heating wire 1 and detection wire 3 are drawn out through the open loop. A notch 4 for cutting off the detection wire 3 is provided on the detection wire 3 of the outer ring, and a through hole 5 for cutting off the detection wire 3 is provided on the two detection wires 3 located in the outer ring.

[0074] A liquid seepage groove 6 is arranged on the surface of the insulating coating layer, one end of the liquid seepage groove 6 is located on the outer periphery of the battery heating membrane, and the other end of the liquid seepage groove 6 communicates with the through hole 5 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap