Automatic gain adjustment method and system for steel rail flaw detection, equipment and storage medium

An automatic gain adjustment and gain adjustment technology, which is applied to the detection of response signals, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc., can solve the time-consuming and troublesome problems of manual adjustment, achieve timely and accurate gain adjustment, and improve detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

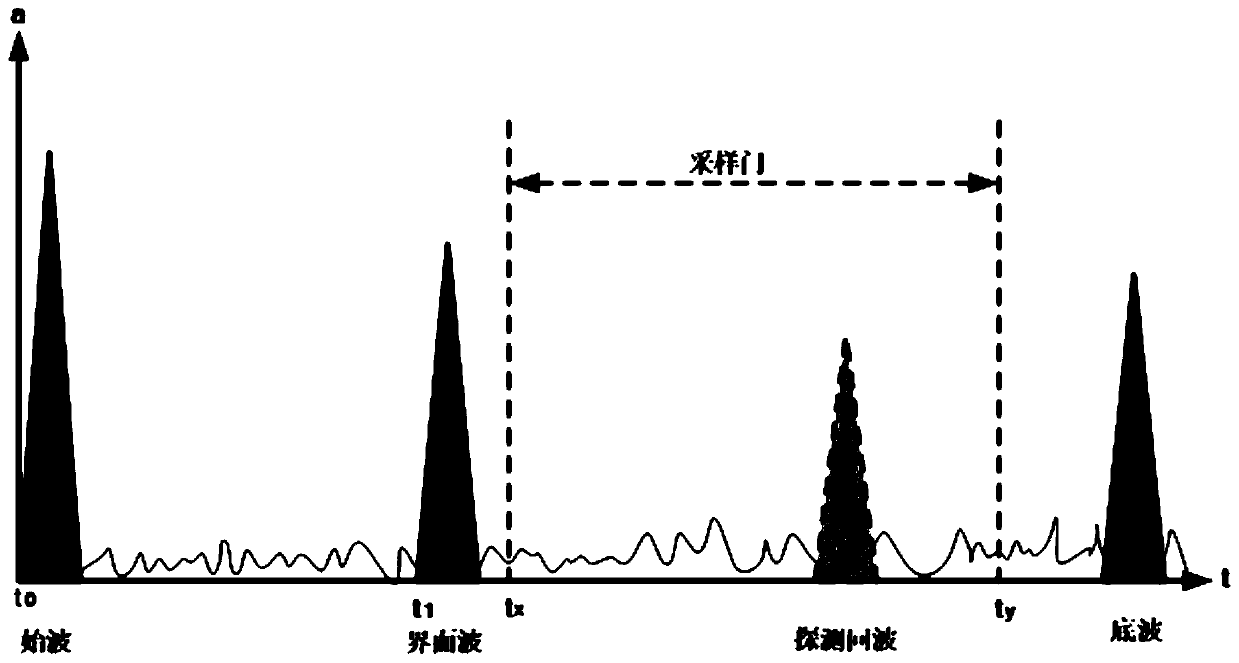

[0047] reference figure 1 , During ultrasonic testing, there will be a messy, clumped weed-like signal near the baseline, called grass wave. When we push the device to a place where there is no damage to the reflection, in the A-scan state, the reflected echo near the bottom line is a grass wave. The grass wave is the reflection of the grains in the rail material. The rail flaw detection generally requires at least a 4mm diameter damage location; through experiments, the echo amplitude of a flat-bottomed hole with a Φ4 unit orthogonal to the ultrasonic main beam is higher than that of the grass. The shape wave is about 30dB, so if we maintain the grass wave at a certain level, such as 10% to 20% of the screen, the refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com