Hanging basket for cantilever casting of small-curvature-radius continuous beam

A technology with small curvature and radius, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., it can solve the problems of lateral displacement of hanging baskets and forward movement of walking tracks, so as to achieve the effect of increasing space and enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

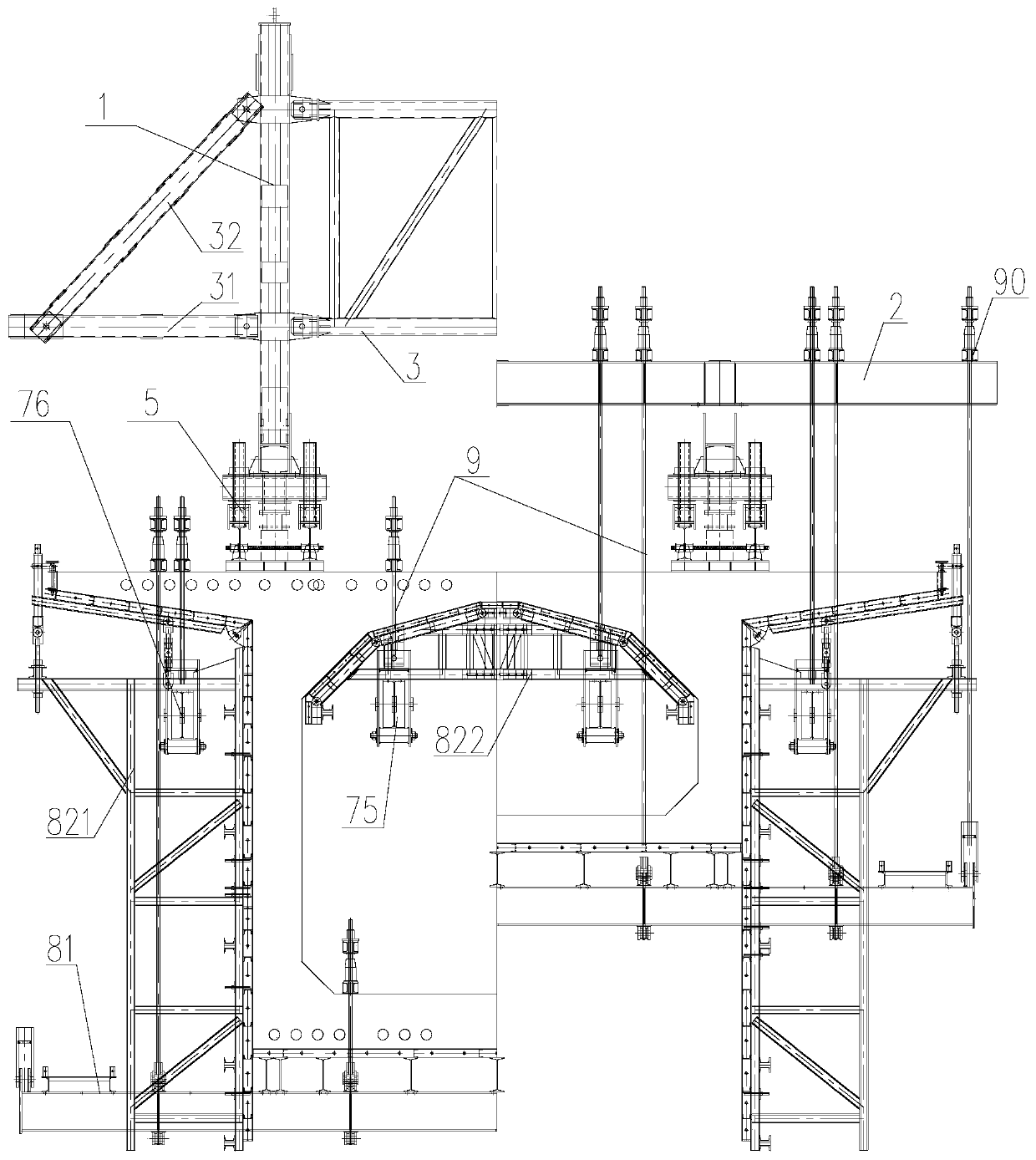

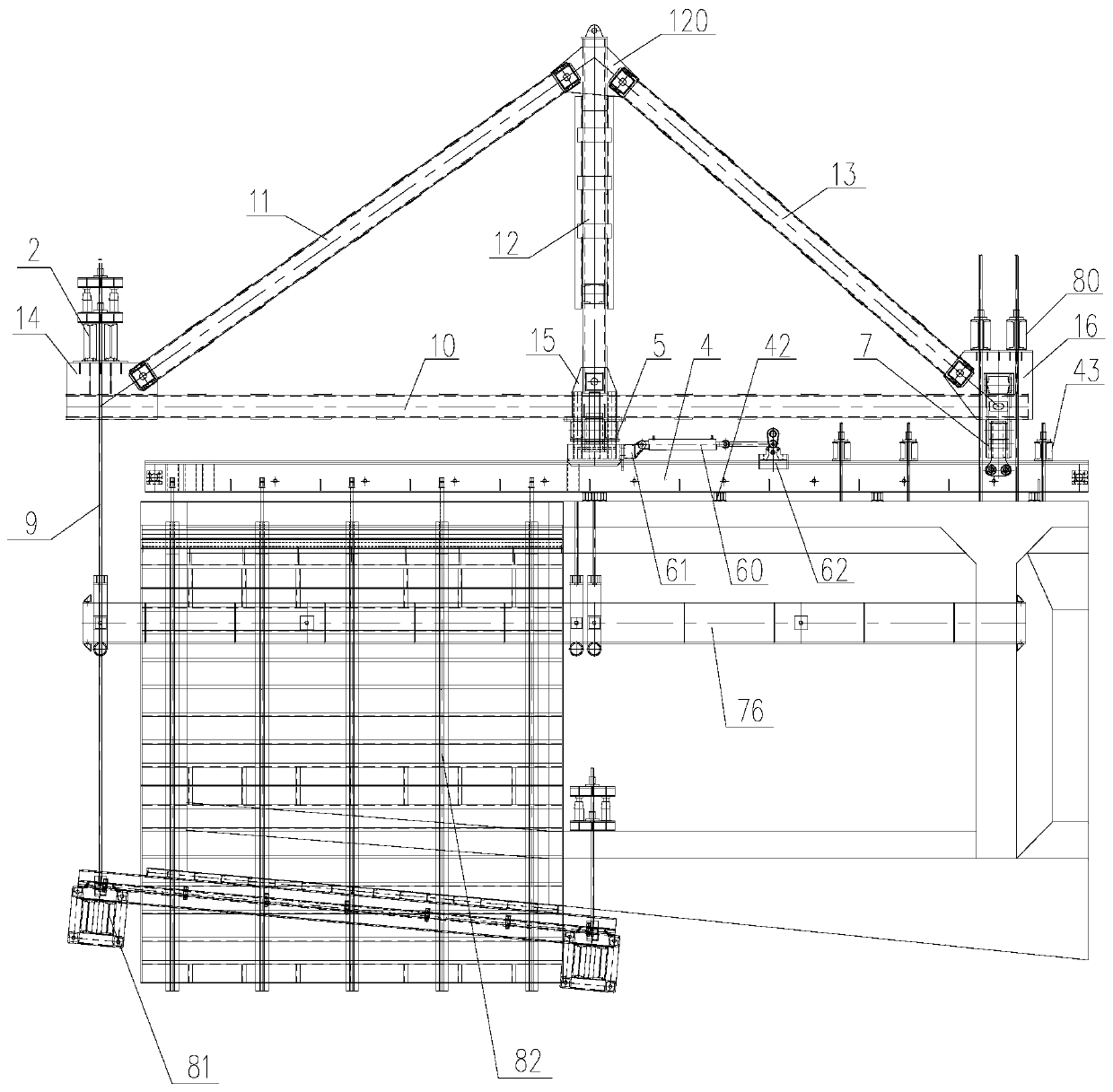

[0044] see Figure 1 to Figure 12 , the hanging basket for cantilever casting small curvature radius continuous beams of the present invention includes a main frame, a bottom mold system 81, a formwork system 82, a suspension system 9, a walking system, an anchoring system 80 and a safety protection system.

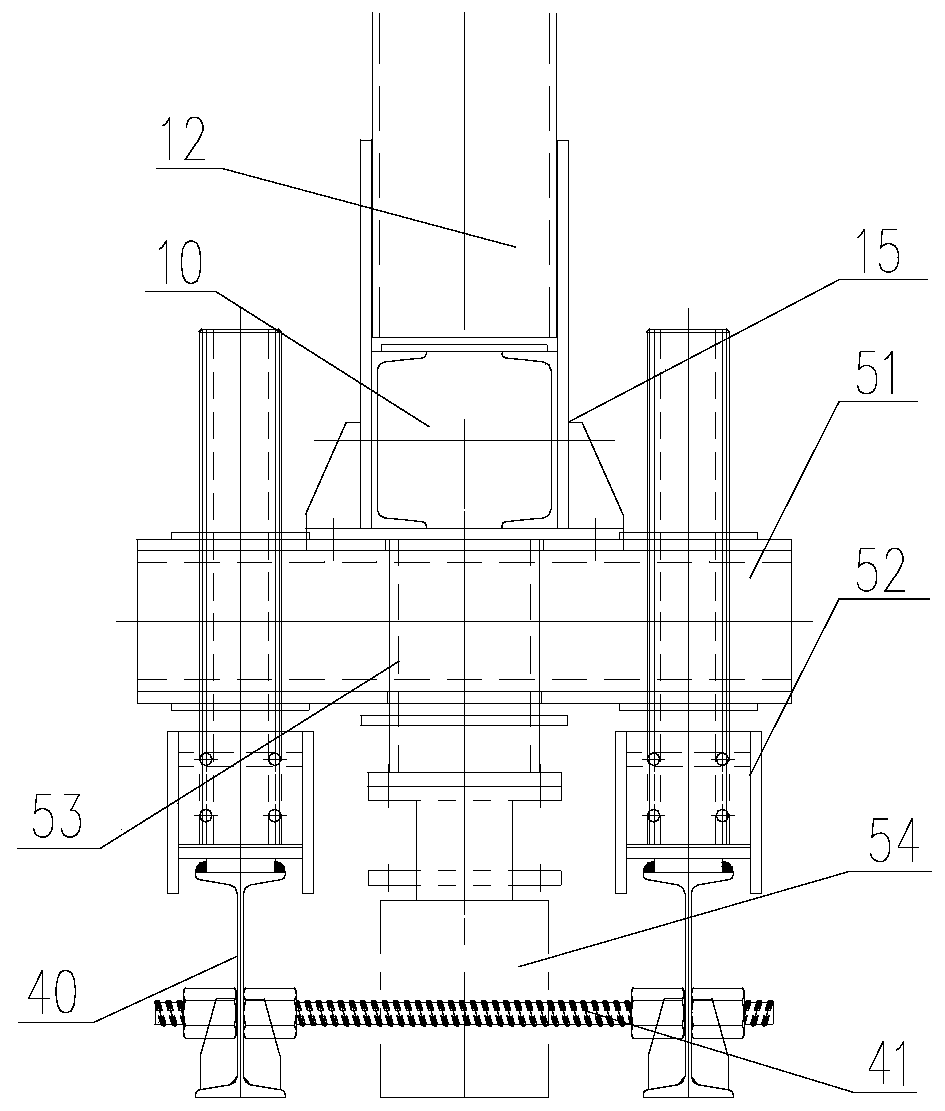

[0045] The main frame includes two triangular main trusses 1, top beams 22 and cross-links 3 with the same structure; each main truss 1 is composed of truss main beams 10, vertical bars 12, front slanting bars 11 and rear slanting bars 13; wherein, the truss main The front end, the middle part and the rear end of the beam 10 are respectively connected with the front end of the front slant bar 11, the lower end of the vertical bar 12 and the rear end of the rear slant bar 13 through the front node seat 14, the middle fulcrum seat 15 and the rear anchor seat 16; The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com