Single-coating water-based UV pearlescent silver powder paint and preparation method thereof

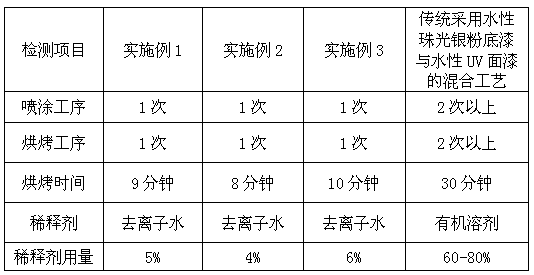

A technology of silver powder paint and pearl powder, which is applied in the direction of coating, device for coating liquid on the surface, pretreatment of surface, etc., can solve the problems of complicated and inconvenient spraying process or processing steps, and long processing time, etc. The effect of solving the harm to human health, shortening the baking time and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A single coating water-based UV pearlescent silver paint and a preparation method thereof, a single coating water-based UV pearlescent silver paint and a preparation method thereof, comprising the following components by weight ratio:

[0034] Styrene-acrylic emulsion 60-80%,

[0035] Propylene Glycol 1-5%,

[0036] Hyperbranched polyol 1-5%,

[0037] Water-soluble highly active monomer 4-10%,

[0038] Water-based pearl powder 2-5%,

[0039] Photoinitiator A 1-5%,

[0040] Photoinitiator B 1-5%,

[0041] Leveling agent 0.1-0.5%,

[0042] Defoamer 0.1-0.5%,

[0043] Deionized water 8-12%,

[0044] Water-based anti-silver additive 0.5-2%,

[0045] Water-based thickener 0.1-0.5%.

[0046] In one embodiment, the photoinitiator A is German BASF photoinitiator Irgacure500, and the photoinitiator B is German BASF photoinitiator IRGACURE 2959.

[0047] In one of the embodiments, the leveling agent is BYK-347 leveling agent from Germany.

[0048] In one embodiment, th...

Embodiment 1

[0053] A kind of single coating waterborne UV pearl luster silver powder paint, it comprises following composition by weight ratio:

[0054] Styrene-acrylic emulsion 70%,

[0055] Propylene Glycol 2%,

[0056] hyperbranched polyol 3%,

[0057] Water-soluble highly active monomer 5%,

[0058] Water-based pearl powder (silver) 3%,

[0059] Photoinitiator A 2%,

[0060] Photoinitiator B 4%,

[0061] Leveling agent 0.3%,

[0062] Defoamer 0.4%,

[0063] Deionized water 9%,

[0064] Water-based anti-silver additive 1%,

[0065] Water-based thickener 0.3%.

[0066] In one embodiment, the photoinitiator A is German BASF photoinitiator Irgacure500, and the photoinitiator B is German BASF photoinitiator IRGACURE 2959.

[0067] In one of the embodiments, the leveling agent is BYK-347 leveling agent from Germany.

[0068] In one embodiment, the defoamer is BASF Dehydran 1620 defoamer.

[0069] In one of the embodiments, the water-based anti-sliver additive of Tego AddBOND 1270 ...

Embodiment 2

[0075] A kind of single coating waterborne UV pearl luster silver powder paint, it comprises following composition by weight ratio:

[0076] Styrene-acrylic emulsion 70%,

[0077] Propylene Glycol 3%,

[0078] hyperbranched polyol 3%,

[0079] Water-soluble highly active monomer 7%,

[0080] Water-based pearl powder 4%,

[0081] Photoinitiator A 4%,

[0082] Photoinitiator B 2%,

[0083] Leveling agent 0.4%,

[0084] Defoamer 0.2%,

[0085] Deionized water 11%,

[0086] Water-based anti-silver additive 1.5%,

[0087] Water-based thickener 0.4%.

[0088] In one embodiment, the photoinitiator A is German BASF photoinitiator Irgacure500, and the photoinitiator B is German BASF photoinitiator IRGACURE 2959.

[0089] In one of the embodiments, the leveling agent is BYK-347 leveling agent from Germany.

[0090] In one embodiment, the defoamer is BASF Dehydran 1620 defoamer.

[0091] In one of the embodiments, the water-based anti-sliver additive of Tego AddBOND 1270 is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com