Method for preparing methylcyclopentadiene dimer from cracked C9 fraction

A technology of methylcyclopentadiene dimer and methylcyclopentadiene, which is applied in the field of preparation of methylcyclopentadiene dimer, can solve the problems of corrosive damage to distillation towers, coking blockage of distillation towers, and single-pass production. Reduce the efficiency and other problems, to achieve the effect of prolonging the service life, high-efficiency production, safe and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

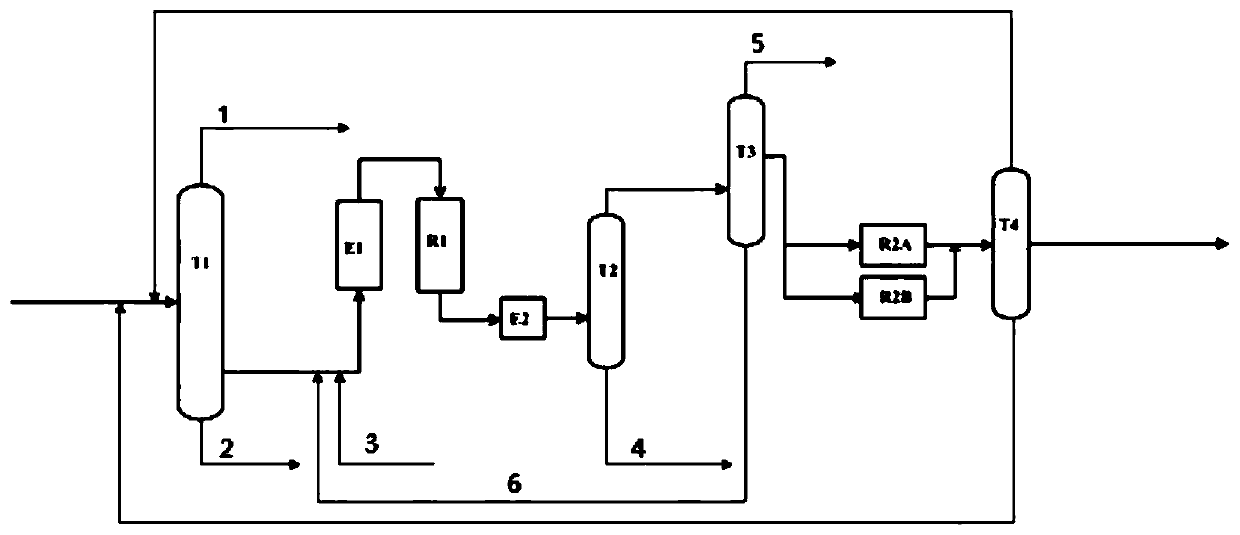

Method used

Image

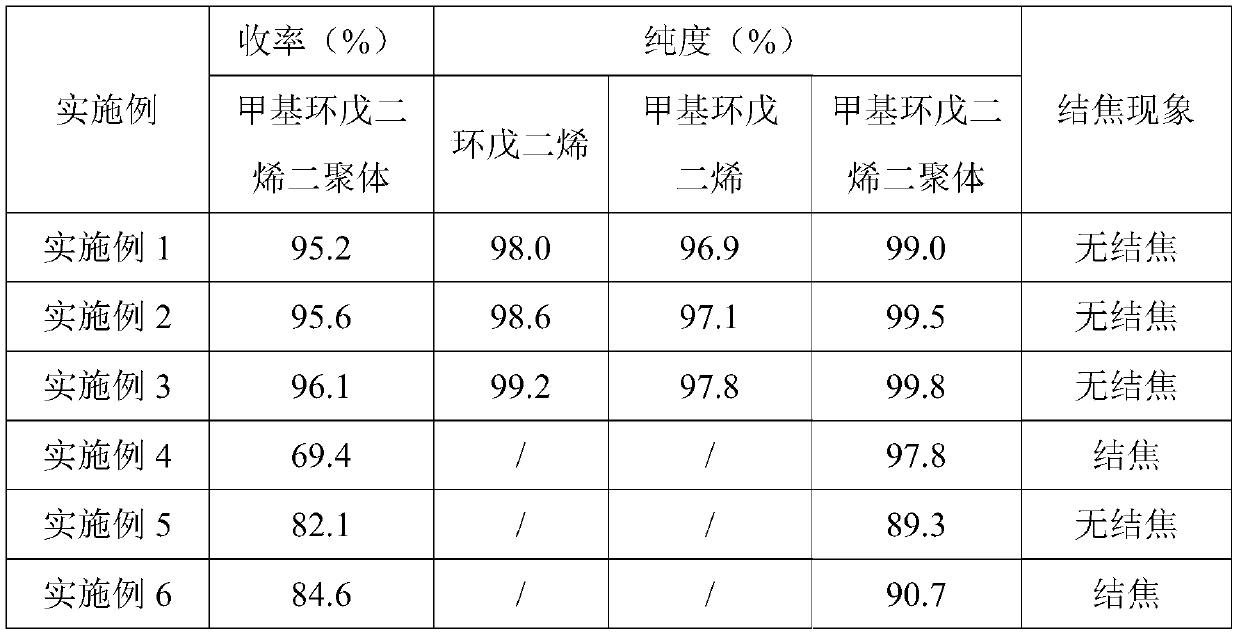

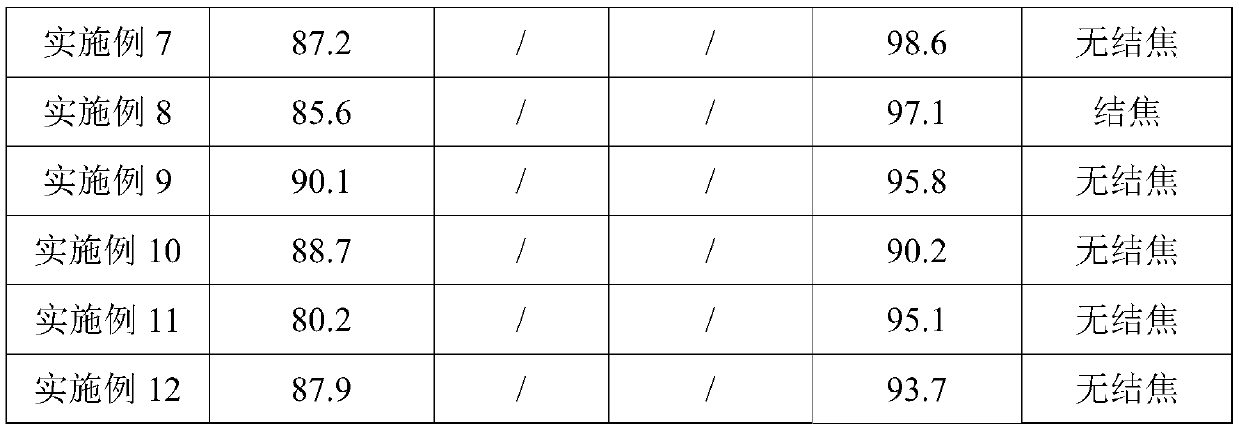

Examples

Embodiment 1

[0071] Embodiment 1 of the present invention provides a kind of method for preparing methylcyclopentadiene dimer from cracking carbon nine cuts, described method for preparing methylcyclopentadiene dimer from cracking carbon nine cuts comprises The following steps:

[0072] (1) The fraction of cracked carbon nine is input into the rectification tower T1 at 7.5t / h, the pressure of the rectification tower T1 is controlled to be 9Kpa, the temperature at the bottom of the tower is 140-150°C, the temperature of the side line is 120-130°C, and the top of the tower is The temperature is 80-90°C, and the reflux ratio is controlled to be 0.8:1; the side line is 890Kg / h rich in C 11 h 14 (The dimer of cyclopentadiene and methylcyclopentadiene) and the material of methylcyclopentadiene dimer, this material and inert solvent enter in the reactor R1 through pre-heater E1 and carry out cracking, cracking stops The time is 5s, the temperature of the pre-heater E1 is controlled to be 170-18...

Embodiment 2

[0081] Embodiment 2 of the present invention provides a kind of method for preparing methylcyclopentadiene dimer from cracking carbon nine cuts, described method for preparing methylcyclopentadiene dimer from cracking carbon nine cuts comprises The following steps:

[0082] (1) The fraction of cracked carbon nine is input into the rectification tower T1 at 8.5t / h, the pressure of the rectification tower T1 is controlled at 11Kpa, the temperature at the bottom of the tower is 140-150°C, and the temperature of the side line is 120-130°C. The temperature is 100~110℃, and the reflux ratio is controlled to be 1.3:1; the side line can get 870Kg / h rich in C 11 h 14 (The dimer of cyclopentadiene and methylcyclopentadiene) and the material of methylcyclopentadiene dimer, this material and inert solvent enter in the reactor R1 through pre-heater E1 and carry out cracking, cracking stops The time is 10s, the temperature of the pre-heater E1 is controlled to be 180-190°C, and the temper...

Embodiment 3

[0091]Embodiment 3 of the present invention provides a kind of method for preparing methylcyclopentadiene dimer from cracking carbon nine cuts, described method for preparing methylcyclopentadiene dimer from cracking carbon nine cuts comprises The following steps:

[0092] (1) The fraction of cracked carbon nine is input to the rectification tower T1 at 8t / h, the pressure of the rectification tower T1 is controlled to be 10Kpa, the temperature at the bottom of the tower is 140-150°C, the temperature of the side line is 120-130°C, and the temperature at the top of the tower is The temperature is 90~100℃, and the reflux ratio is controlled to be 1:1; the side line can get 880Kg / h rich in C 11 h 14 (The dimer of cyclopentadiene and methylcyclopentadiene) and the material of methylcyclopentadiene dimer, this material and inert solvent enter in the reactor R1 through pre-heater E1 and carry out cracking, cracking stops The time is 8s, the temperature of the pre-heater E1 is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com