A kind of strong agent suitable for concrete prepared by machine-made sand and preparation method of mother liquor thereof

A technology of concrete and strengthening agent, which is applied in the field of concrete additives, which can solve the problems of large dispersion of concrete strength, poor concrete homogeneity, poor concrete workability, etc., and improve the poor water retention performance, strength and durability of concrete Effects of performance improvement and durability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

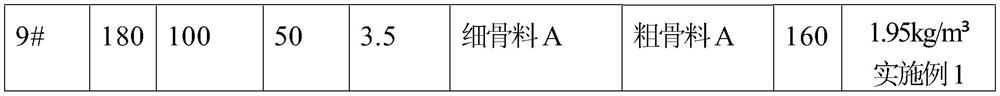

Examples

Embodiment 1

[0042] This embodiment provides a method for preparing a mother liquor of a strong agent suitable for machine-made sand preparation, comprising the following steps:

[0043] Concrete strength agent mother liquor ingredients: isopentenol polyoxyethylene ether 0.8Kg, triethanolamine 2Kg, cold gel 1.5Kg, polyisoprene latex 1Kg, modified starch 1Kg, sodium lignosulfonate 2Kg, filler 0.8 Kg and water 6Kg.

[0044] S1: Add prenol polyoxyethylene ether, sodium lignosulfonate, and fillers into the reactor, and stir at a temperature of 70-80° C. for 1.5 hours to obtain a mixture A;

[0045] S2: stirring triethanolamine, modified starch, cold gelatin, and polyisoprene latex in water for 1 hour to obtain mixture B;

[0046] S3: Pour the mixture A into the mixture B, mix and stir for 1 hour to obtain the mother liquor of concrete strengthening agent, the mother liquor is 15.1Kg.

Embodiment 2

[0048] This embodiment provides a method for preparing a mother liquor of a strong agent suitable for machine-made sand preparation, comprising the following steps:

[0049] Concrete strength agent mother liquor ingredients: isopentenol polyoxyethylene ether 0.2Kg, triethanolamine 1.6Kg, cold gel 0.8Kg, polyisoprene latex 0.6Kg, modified starch 0.6Kg, sodium lignosulfonate 1.2Kg , Filling material 0.2Kg and water 4Kg.

[0050] According to the preparation method of Example 1, 9.2Kg of mother liquor was obtained.

Embodiment 3

[0052] This embodiment provides a method for preparing a mother liquor of a strong agent suitable for machine-made sand preparation, comprising the following steps:

[0053] Concrete strength agent mother liquor ingredients: isopentenol polyoxyethylene ether 0.6Kg, triethanolamine 1.6Kg, cold gel 1.2Kg, polyisoprene latex 0.8Kg, modified starch 0.8Kg, sodium lignosulfonate 1.6Kg , Filling material 0.6Kg and water 5Kg.

[0054] According to the preparation method of Example 1, 12.2Kg of mother liquor was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com