Logistics transport cargo box anti-slip locker

A locker and cargo box technology, which is applied in the field of logistics and transportation, can solve the problems of incapable of portable mobile use, high installation cost, collision and damage of equipment or cargo boxes, etc., so as to achieve convenient portable mobile use, simple and fast use and installation , the effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

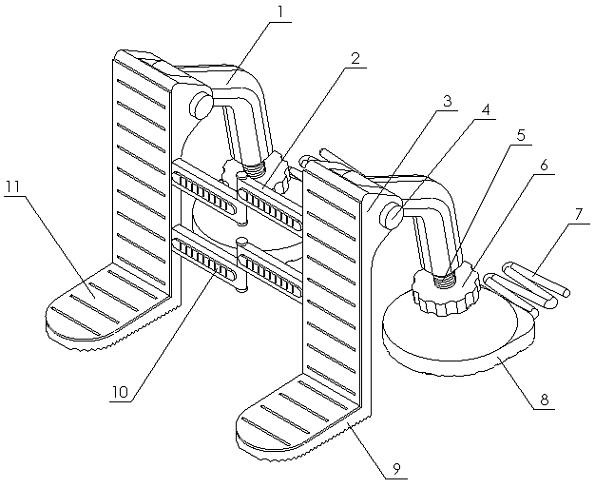

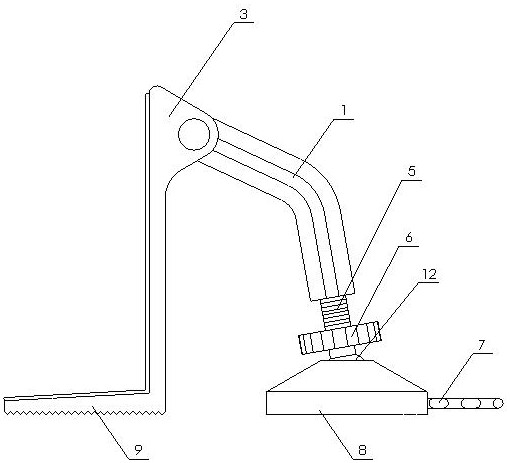

[0025] An anti-slip locker for a logistics transport container of the present invention is realized in this way. The anti-slip locker for a logistics transport container of the present invention is composed of two supporting parts that can deflect relative to each other, and two sets of connecting rods ( 2) Hinged, the supporting part is composed of a supporting bent rod (1), a supporting plate (3), a connecting shaft (4), a screw rod (5), a screw cap (6), a bending piece (7), and a base (8) , an insert plate (9), a gasket (10), a wear-resistant pad (11) and a spherical joint (12), and one end of the support bending rod (1) is hinged to one end of the support plate (3) through a connecting shaft (4). The insertion plate (9) is placed on the other end of the support plate (3), the angle between the insertion plate (9) and the support plate (3) is 95°-100°, the support bending rod (1) and the insertion plate ( 9) Located on both sides of the supporting plate (3), the bending ang...

Embodiment 2

[0032] The difference between embodiment 2 and embodiment 1 is that the connection between the two supporting parts is connected by the auxiliary rod, and the two ends of the auxiliary rod are respectively hinged with the connecting rod (2), which can be further used for the transportation of machine tool equipment. Special-shaped corners are attached to the protective support to improve the stability of the support, and the auxiliary rod can increase the angle adjustment range between the two support parts;

Embodiment 3

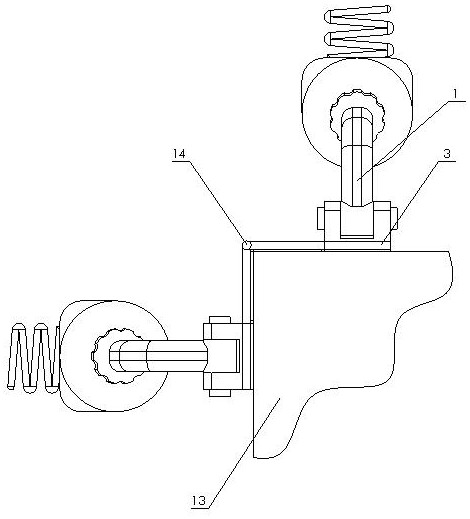

[0034] The difference between Embodiment 3 and Embodiment 1 is that only one of the two support parts is provided with a support rod, and a foldable and accommodated support arm is added at the hinge shaft (14) of the connecting rod (2), and the support arm is composed of It is composed of a sleeve rod for storage and a support foot hinged to the end of the sleeve rod for support. The sleeve rod is fixed by the hinge shaft (14). Embodiment 3 is targeted at different weight distributions of the equipment to be fixed. The position of the support point saves space and provides auxiliary support;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com