Gooseneck trailer longitudinal beam spliced in segmented manner, trailer frame and trailer

A segmented splicing and gooseneck technology, which is applied to the tractor-trailer combination, the connection between the superstructure subassemblies, and the motor vehicle, can solve the problem of difficult processing, large space occupation, and many models of longitudinal beam webs. and other problems, to achieve the effect of high structural strength and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

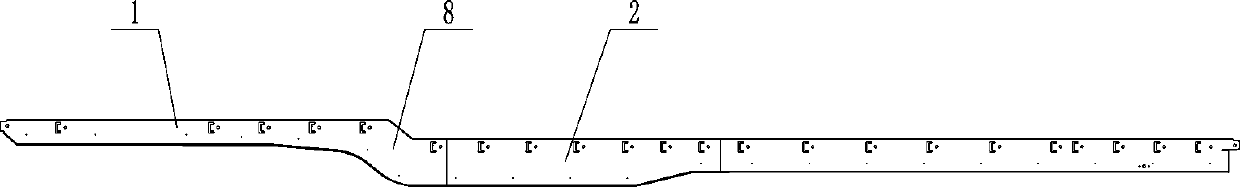

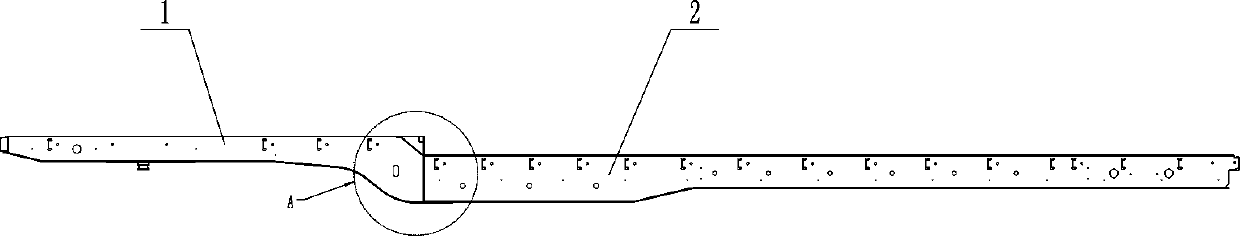

[0028] Such as image 3 , Figure 4 , Pic 4-1 and Figure 4-2 As shown, a segmentally spliced gooseneck trailer longitudinal beam includes a front longitudinal beam 1, a rear longitudinal beam 2 and a splicing structure, and the front longitudinal beam 1 and rear longitudinal beam 2 are divided at the gooseneck and connected by a splicing structure together; the splicing structure includes a connecting vertical plate 3, and the two sides of the connecting vertical plate 3 are respectively welded and fixed on the web 12 of the front longitudinal beam 1 and the web 22 of the rear longitudinal beam 2, so The bottom end of the connecting vertical plate 3 is welded and fixed to the lower wing plate 13 of the front longitudinal beam 1, the top end of the connecting vertical plate 3 is welded and fixed to the front longitudinal beam 1, and the end of the lower wing plate 13 of the front longitudinal beam 1 faces The rear extension is such that the lower wing plate 23 of the rea...

Embodiment 2

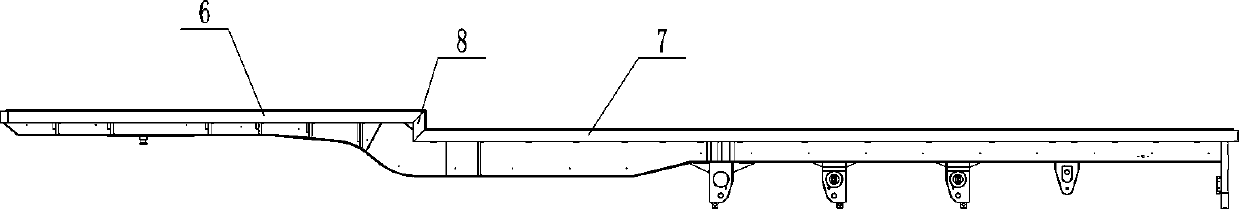

[0037] Such as Figure 5 As shown, a trailer frame with the segmented gooseneck trailer longitudinal beam includes a front frame 6 and a rear frame 7, and the front frame 6 and the rear frame 7 are divided at the gooseneck, The front frame 6 and the rear frame 7 are spliced and fixed together through the splicing structure, the gooseneck platform cross brace 4 spans the two front longitudinal beams of the front frame 6, and the gooseneck The two ends of the platform cross brace 4 are respectively fixed at the joints at the two ends of the two front and rear vehicle frames.

[0038] Through splicing, the rear frame 7 of uniform standard can be adapted to the front frame 6 of different standards, so as to meet the highly customized demand and reduce the production cost and process requirements. At the same time, the structural design of the gooseneck platform cross brace 4 makes The stress at the splicing structure can be transmitted to the entire frame through the cross brac...

Embodiment 3

[0040] Such as Figure 6 As shown, a trailer with the trailer frame includes a trailer frame, traveling wheels 10 and a compartment 9. The trailer has the advantages of low production cost, simple manufacturing process, and adaptability to highly customized requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com