A high-density component multi-stage blind insertion intelligent assembly device and blind insertion method

An assembly device and high-density technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of small pinholes of radio frequency connectors, high density of internal components, and limited space of radio frequency devices, so as to avoid two Second misalignment, ensure blind mating accuracy and connection reliability, and reduce the effect of human disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

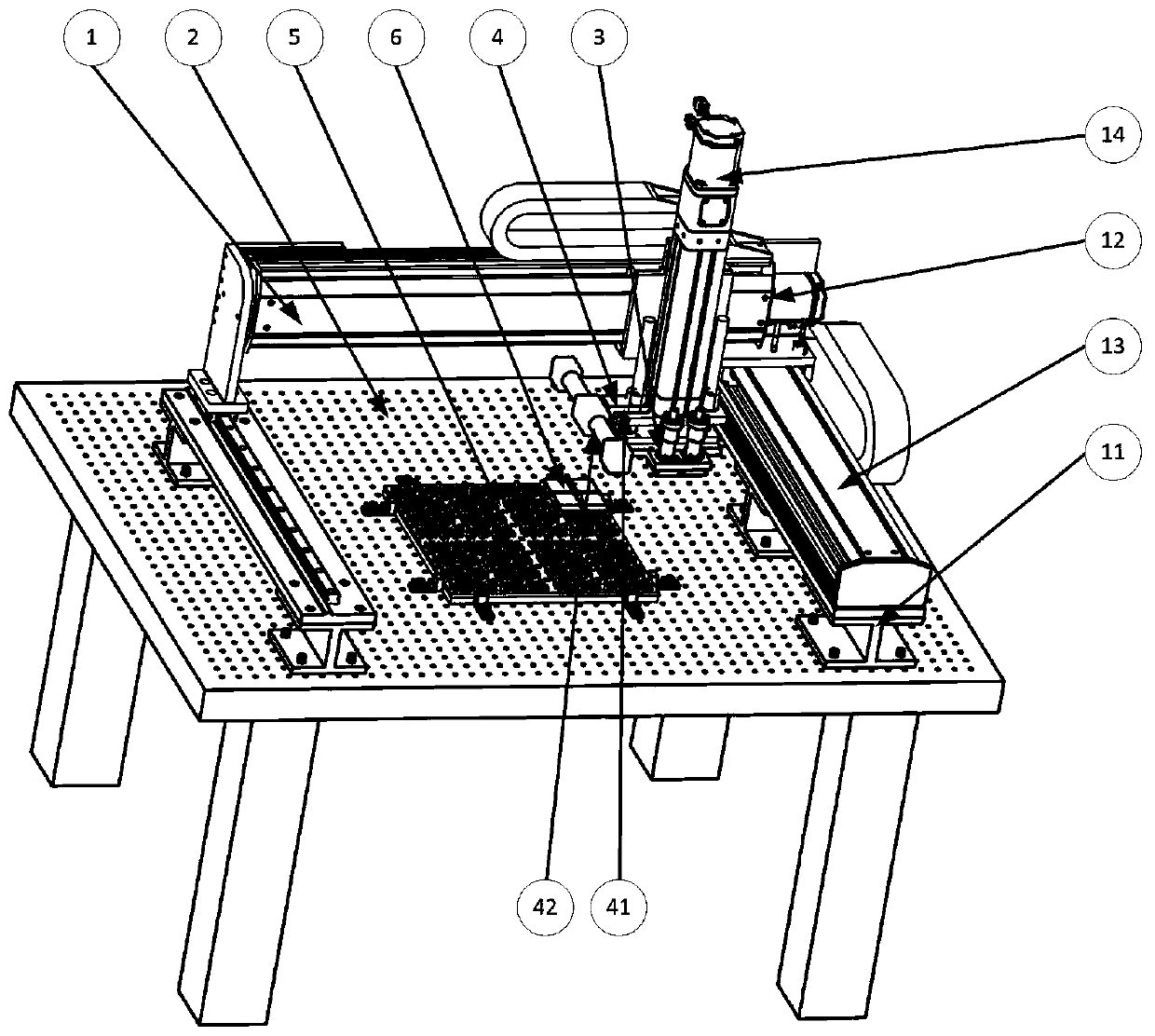

[0027] Such as figure 1 as shown, figure 1 It is a structural view of the intelligent assembly device for multi-level blind insertion of high-density components; the intelligent assembly device for multi-level blind insertion of high-density components in the present invention includes a three-dimensional servo motion platform 1, a precision optical platform 2, a TR component grabbing unit 3, The laser scanning unit 4, the three-dimensional servo motion platform 1 is installed on the precision optical platform 2, the TR component grabbing unit 3 and the laser scanning unit 4 are installed on the three-dimensional servo motion platform 1, so The three-dimensional servo motion platform 1 is used to control the movement of the TR component grasping unit 3 and the laser scanning unit 4 in three directions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com