Hoisting device capable of self-locking and unlocking in nuclear environment

A hoisting device and environment technology, applied in the field of hoisting forks, can solve the problems of large shaking, difficult assembly, low installation and positioning accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

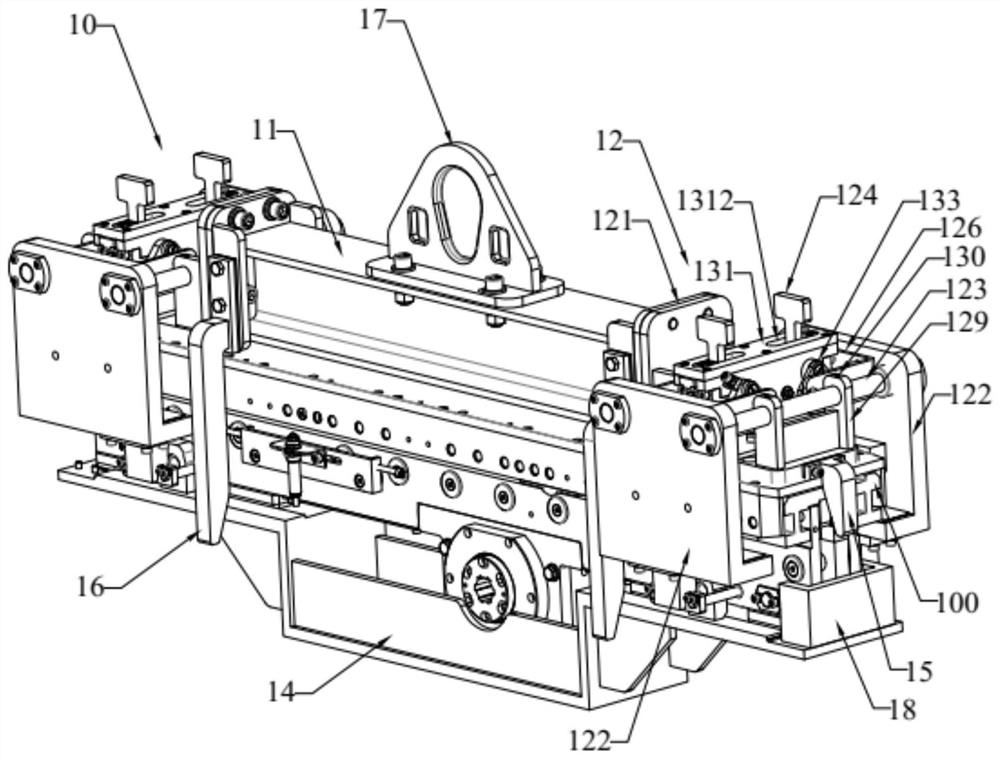

[0021] Such as figure 1 As shown, a lifting device 10 capable of self-locking and unlocking in a nuclear environment according to the present invention includes: a hanging beam 11 , a clamping mechanism 12 and a supporting base 14 . Two clamping mechanisms 12 are used to clamp the pallet fork 100 to replace the pallet fork 100 . The support base 14 is used to support the fork 100 from the bottom of the fork 100 to install the fork 100 . Two clamping mechanisms 12 are respectively arranged at two ends of the suspension beam 11 so as to clamp the fork 100 from both ends of the fork 100 so as to carry the fork 100 stably. The support base 14 is fixed to the fork 100 from the bottom of the fork 100 to support and install the fork 100 .

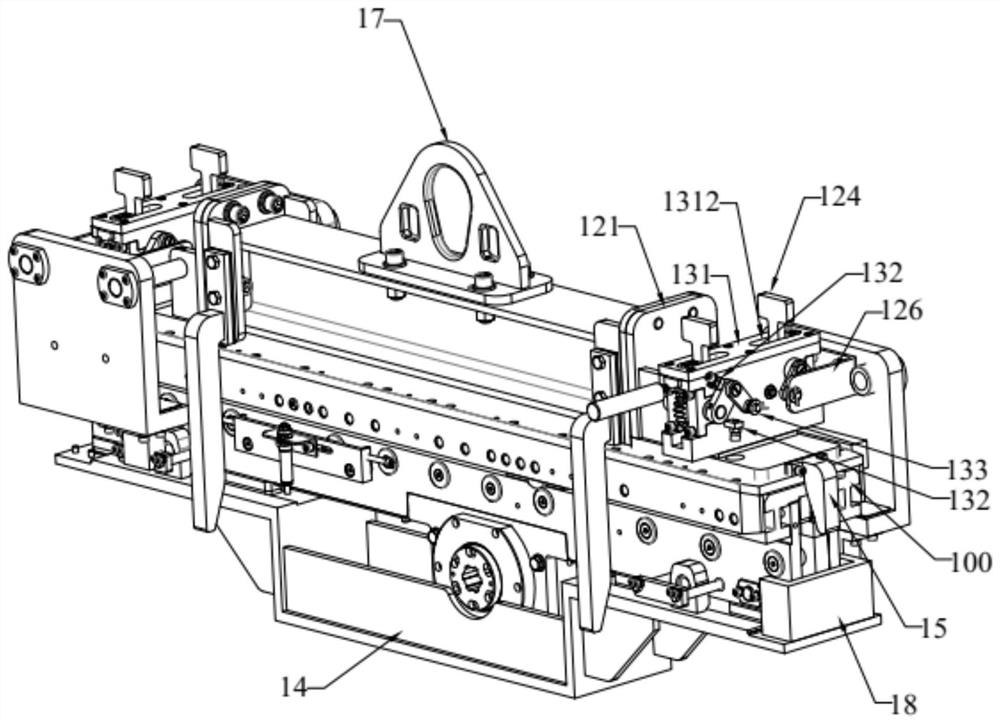

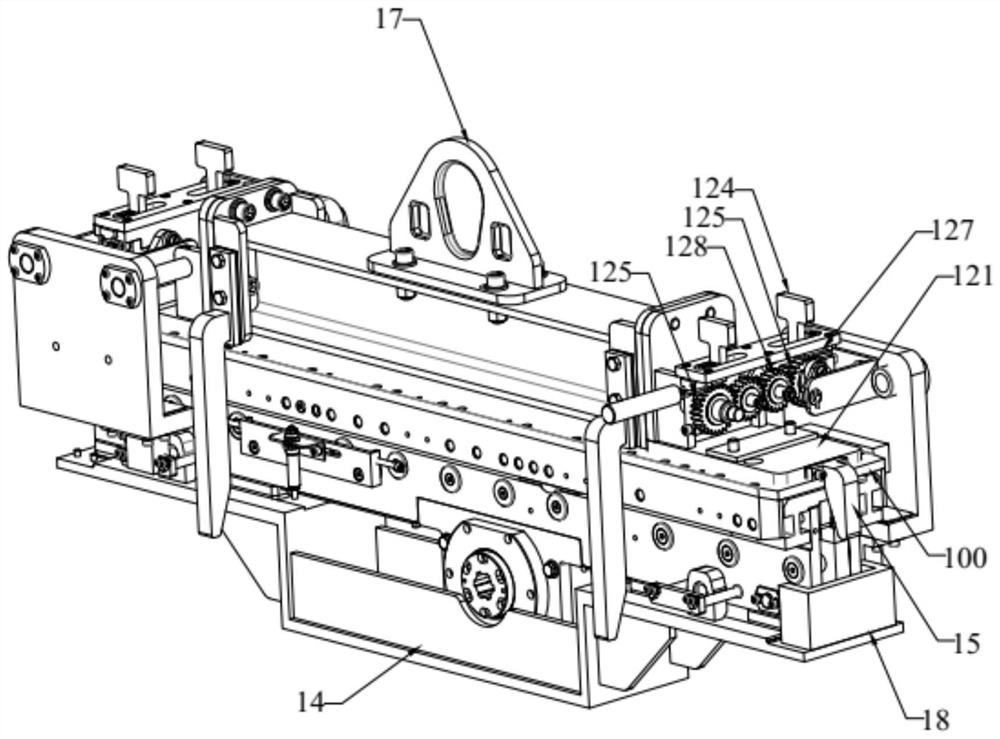

[0022] figure 2 and image 3 It further discloses the internal structure of the lifting device 10 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com