Automatic guide transport vehicle for cylinder block assembly

A technology of automatic guidance and transport vehicles, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., which can solve the problems of automatic cylinder manipulator docking, pick-and-place, etc., and achieve easy extraction, reduced friction, and relative position requirements loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

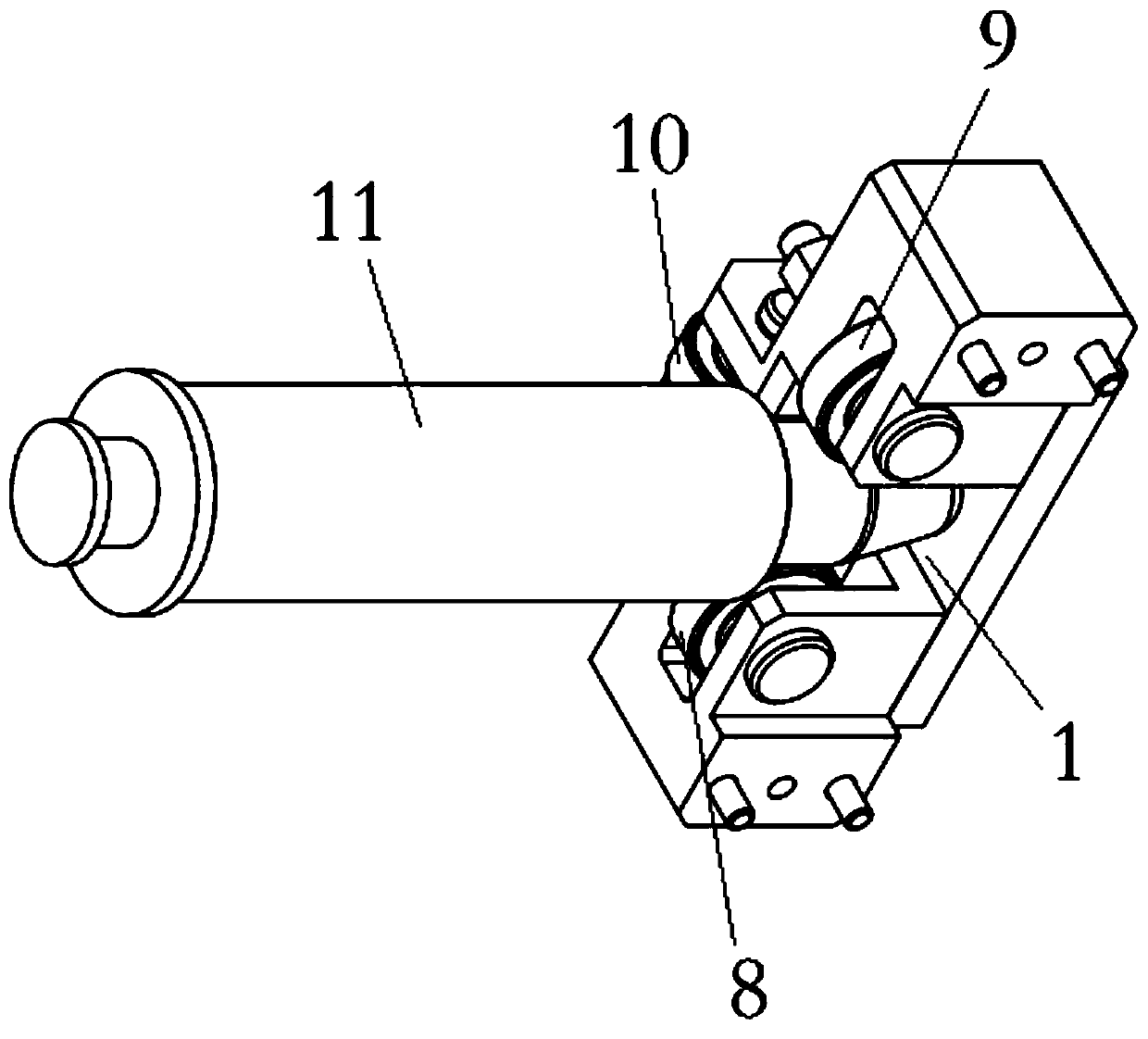

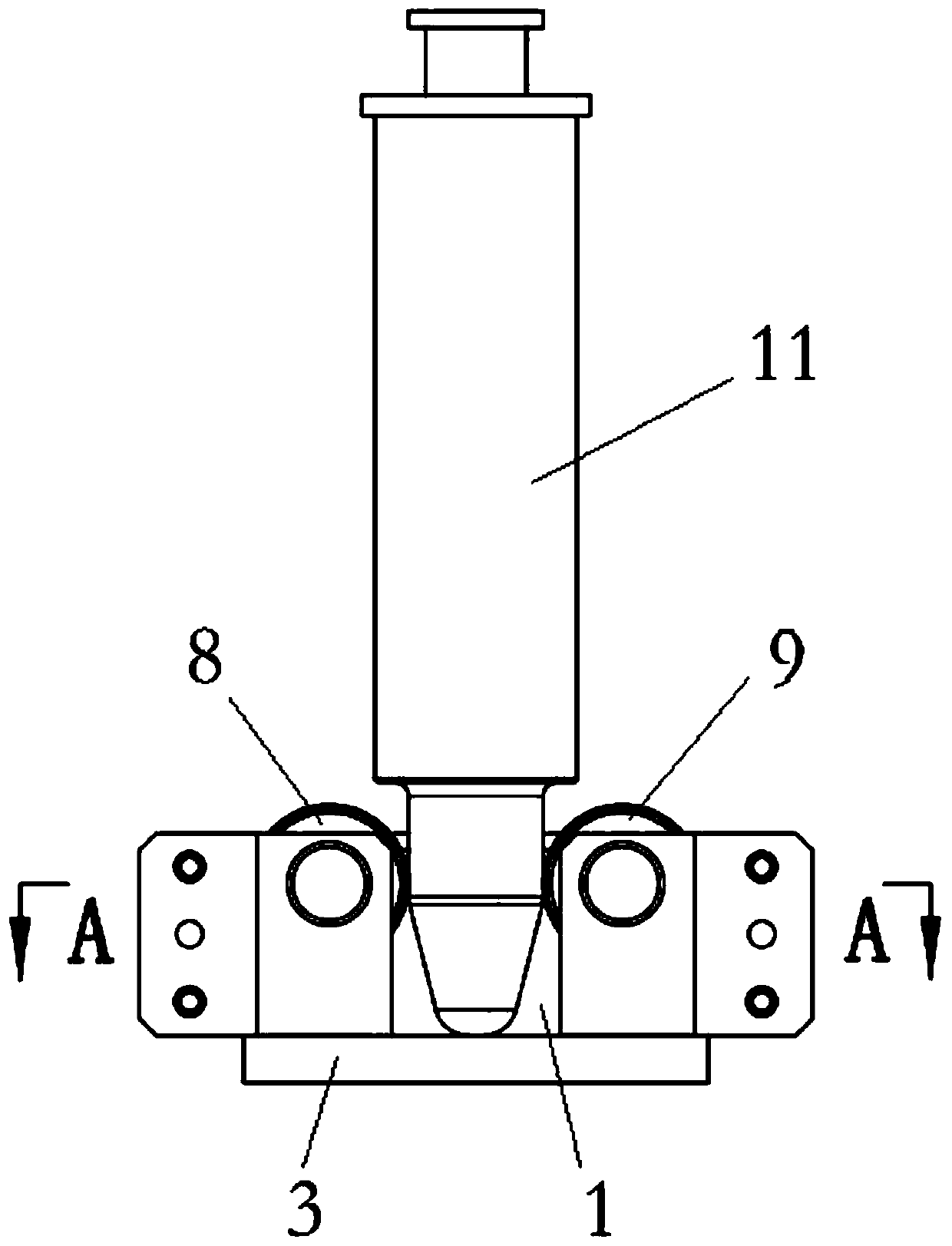

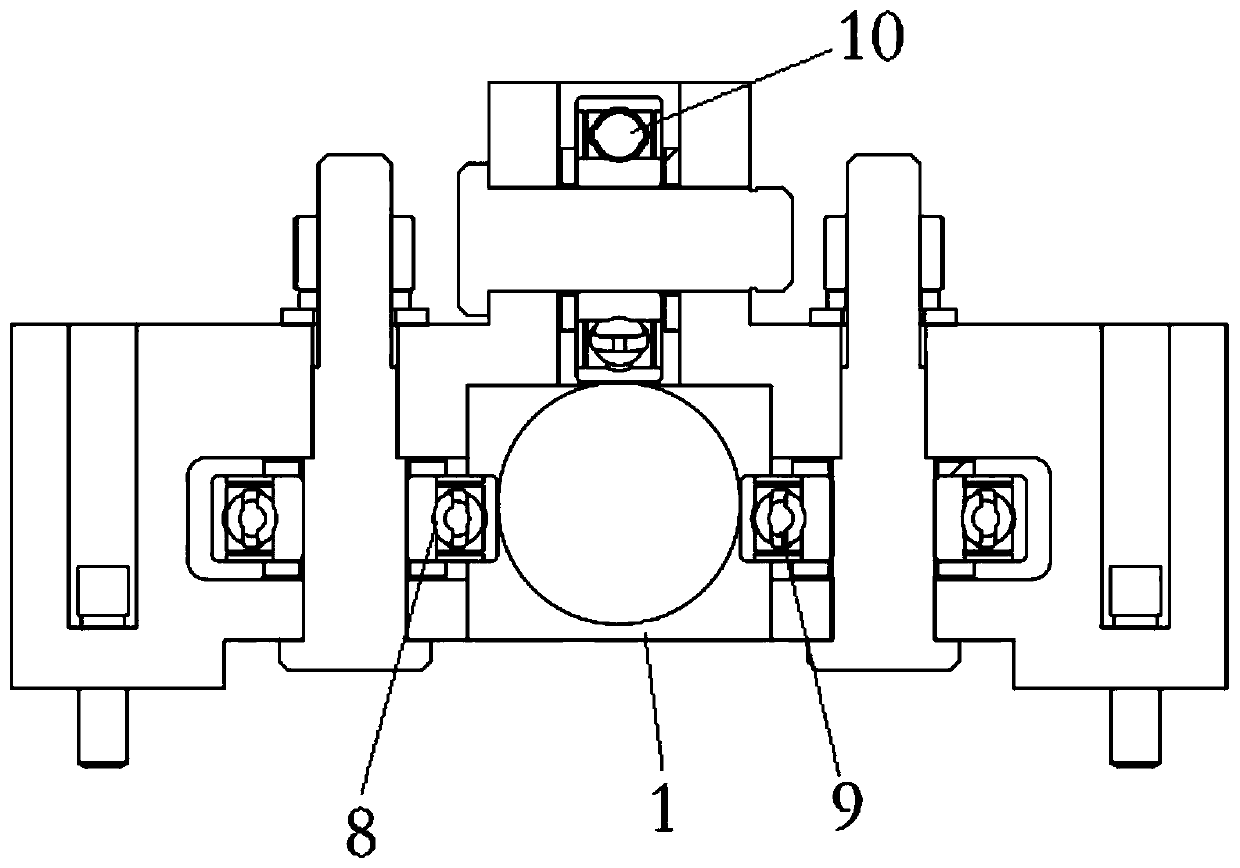

[0058] The positioning structure provided by this embodiment, such as figure 1 As shown, a base is included, and a positioning hole 1 suitable for inserting a positioning pin 11 is provided on the base. On the left and right sides and the upper side of the positioning hole 1, a rotating part is respectively arranged, and the rotating part can be a bearing, and the bearing has three, the first bearing 8, the second bearing 9 and the third bearing 10, through the first bearing 8 and the second bearing 9 are used for positioning the positioning structure in the left and right directions, and the third bearing 10 is used for positioning the positioning structure in the up and down direction. The bearing as a rotating part has the opening direction towards the positioning hole 1, and the edge of the opening protrudes outwards. When the positioning pin 11 extends towards the direction of the positioning hole, as long as it touches the edge of the bearing, it can move along the direc...

Embodiment 2

[0065] The turntable integration provided by this embodiment, such as Figure 6 As shown, it includes a rotating disk 22, the rotating disk 22 is an annular structure, the central position is provided with a central hole, and one side is close to the precision divider connected with its rotating outer ring through the central shaft, and the precision divider also has a fixed inner ring. The inner ring protrudes outward through the central hole, and the precision divider drives the rotating disk to realize the customization of rotation; the other side of the rotating disk 22 is fixedly connected with the connecting frame 15, and the connecting frame 15 is provided with a slot 16 , the slot and the plug-in on the fixed plate of the cylinder block are used in conjunction, and the cylinder body is articulated on the connecting frame 15.

[0066] Such as Figure 7 As shown, the connecting frame 15 is connected to the locking piece 18 by rotating the rotating shaft 26 on one side o...

Embodiment 3

[0076] The automatic guided transport vehicle used for cylinder block assembly provided by this embodiment, such as Figure 12 As shown, there is an automatic guided transport vehicle body 14, its carrying section is in the front, and four positioning structures described in Embodiment 1 are installed on the left and right sides of the automatic guided transport vehicle body. The carrying section of the car body is fixedly connected with the cylinder body through the turntable integration 28 provided in Embodiment 2.

[0077] Specifically, the positioning structures 27 are respectively arranged on the left and right sides near the front end of the vehicle body, and on the left and right sides near the rear end of the vehicle body. When positioning the automatic guided vehicle, the positioning pin 11 is inserted into the positioning hole 1 of the positioning structure through the drive of the cylinder, so that the automatic guided transport vehicle can be positioned in the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com