Convenient-to-use gluing device for linear motor magnet

A technology of linear motors and gluing devices, which is applied to the device and coating of surface coating liquids, can solve the problems of affecting the manufacture of linear motors, increasing the burden on staff, and low efficiency of gluing, so as to achieve easy promotion and gluing The effect of high glue efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

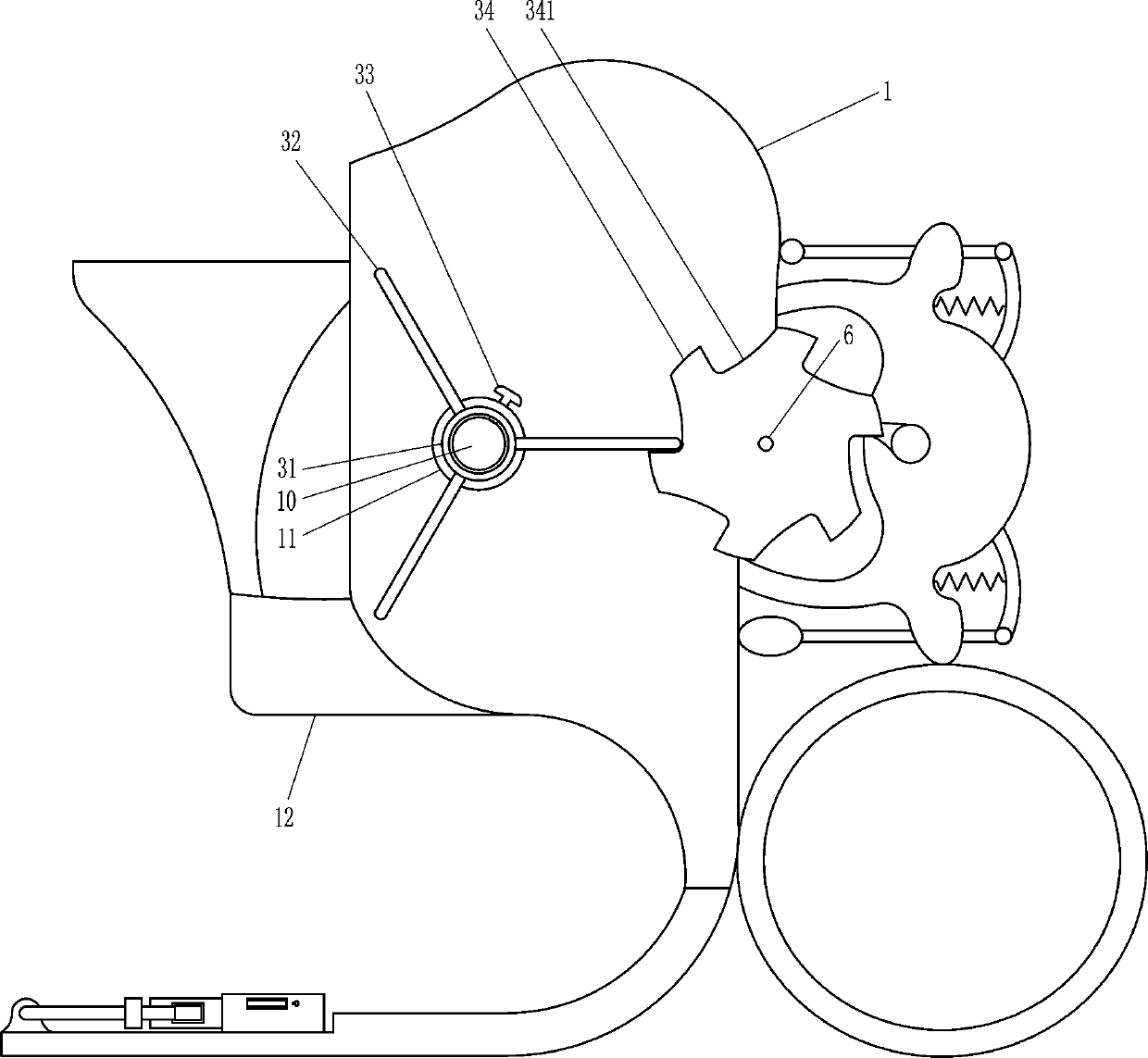

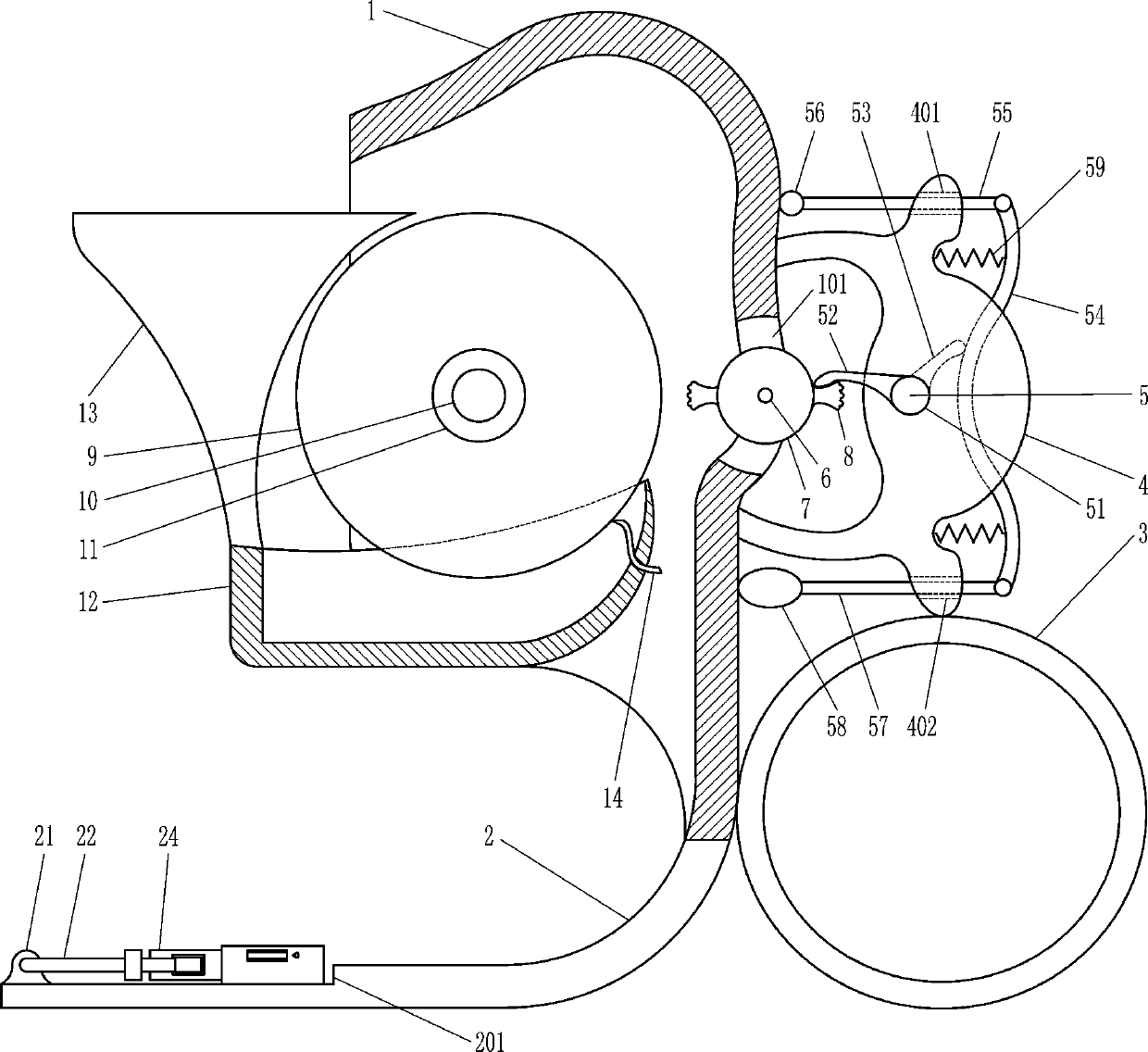

[0018] An easy-to-use gluing device for linear motor 43 magnets, such as figure 1As shown, it includes a cover body 1, an arc-shaped worktable 2, a support ring 3, a mounting plate 4, a vibration device 5, a small rotating shaft 6, a rotating disk 7, a finger 8, a large rubber roller 9, and a large rotating shaft 10 , large bearing 11, cylinder block 12, material spreader 13 and arc pipe 14, the lower end of cover body 1 is connected with the upper right end of arc workbench 2 by welding, and the left side of arc workbench 2 top is open There is a large rectangular groove 201, the lower end of the right side of the cover body 1 is fixedly connected with a support ring 3, and the right side of the cover body 1 is fixedly connected with a mounting plate 4, and the lower end of the mounting plate 4 is fixedly connected with the top of the support ring 3. The upper end of the plate 4 has a first guide hole 401, the lower end of the mounting plate 4 has a second guide hole 402, the...

Embodiment 2

[0020] An easy-to-use gluing device for linear motor 43 magnets, such as figure 1 As shown, it includes a cover body 1, an arc-shaped worktable 2, a support ring 3, a mounting plate 4, a vibration device 5, a small rotating shaft 6, a rotating disk 7, a finger 8, a large rubber roller 9, and a large rotating shaft 10 , large bearing 11, cylinder block 12, material spreading platform 13 and arc pipe 14, the lower end of cover body 1 is fixedly connected with arc workbench 2, and the left side of arc workbench 2 top has a large rectangular groove 201, cover The lower end of the right side of the body 1 is affixed with a support ring 3, the right side of the cover body 1 is affixed with a mounting plate 4, the lower end of the mounting plate 4 is fixedly connected with the top of the support ring 3, and the upper end of the mounting plate 4 is provided with a second A guide hole 401, a second guide hole 402 is opened on the lower end of the mounting plate 4, a large movable groov...

Embodiment 3

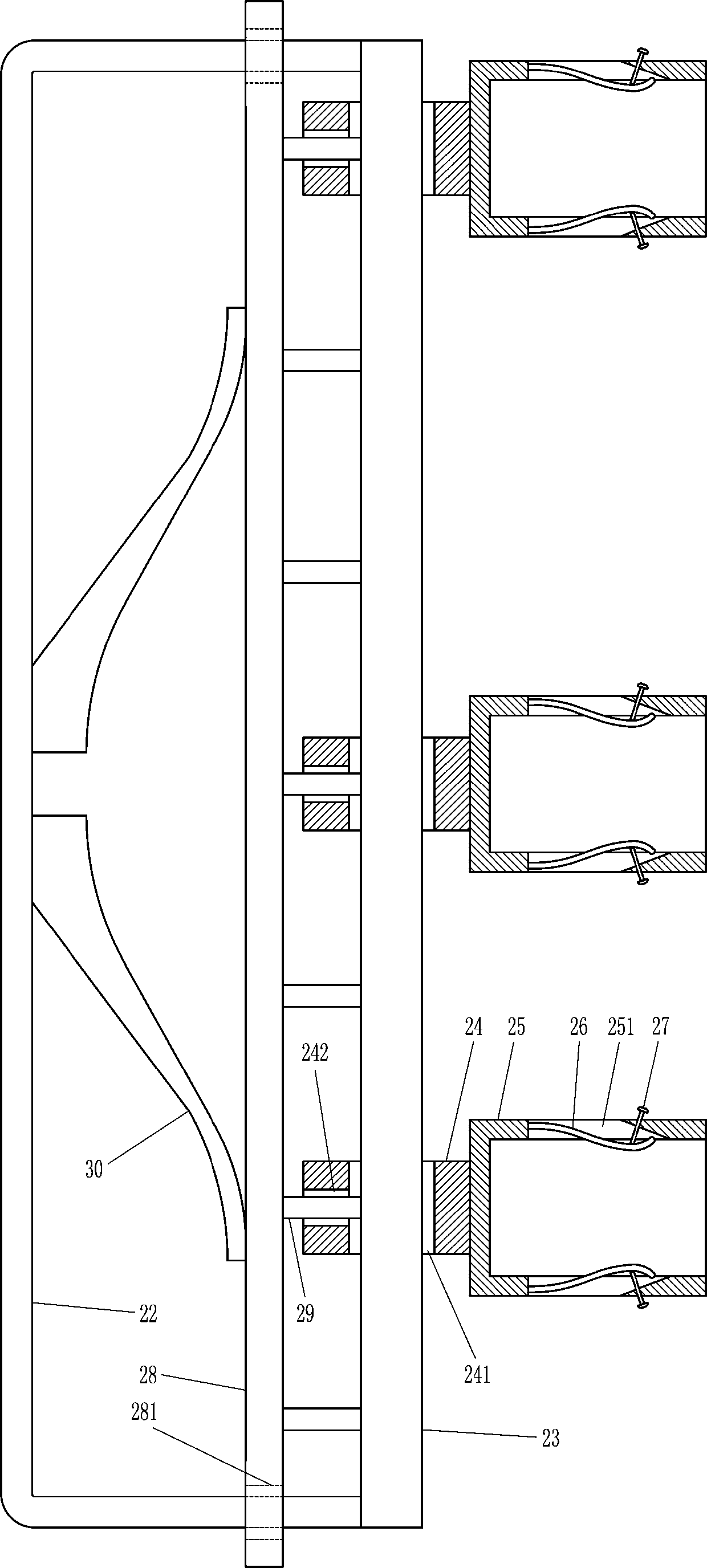

[0023] An easy-to-use gluing device for linear motor 43 magnets, such as Figure 1-3 As shown, it includes a cover body 1, an arc-shaped worktable 2, a support ring 3, a mounting plate 4, a vibration device 5, a small rotating shaft 6, a rotating disk 7, a finger 8, a large rubber roller 9, and a large rotating shaft 10 , large bearing 11, cylinder block 12, material spreading platform 13 and arc pipe 14, the lower end of cover body 1 is fixedly connected with arc workbench 2, and the left side of arc workbench 2 top has a large rectangular groove 201, cover The lower end of the right side of the body 1 is affixed with a support ring 3, the right side of the cover body 1 is affixed with a mounting plate 4, the lower end of the mounting plate 4 is fixedly connected with the top of the support ring 3, and the upper end of the mounting plate 4 is provided with a second A guide hole 401, a second guide hole 402 is opened on the lower end of the mounting plate 4, a large movable gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com