Visualization device and method for visualizing particle deposition process in filter.

A sedimentation process and filter technology, which is applied in the field of visualization devices for the particle deposition process inside the filter, can solve the problems that it is difficult to truly reflect the deposition distribution law, and achieve the effects of convenient experimental observation, portability, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

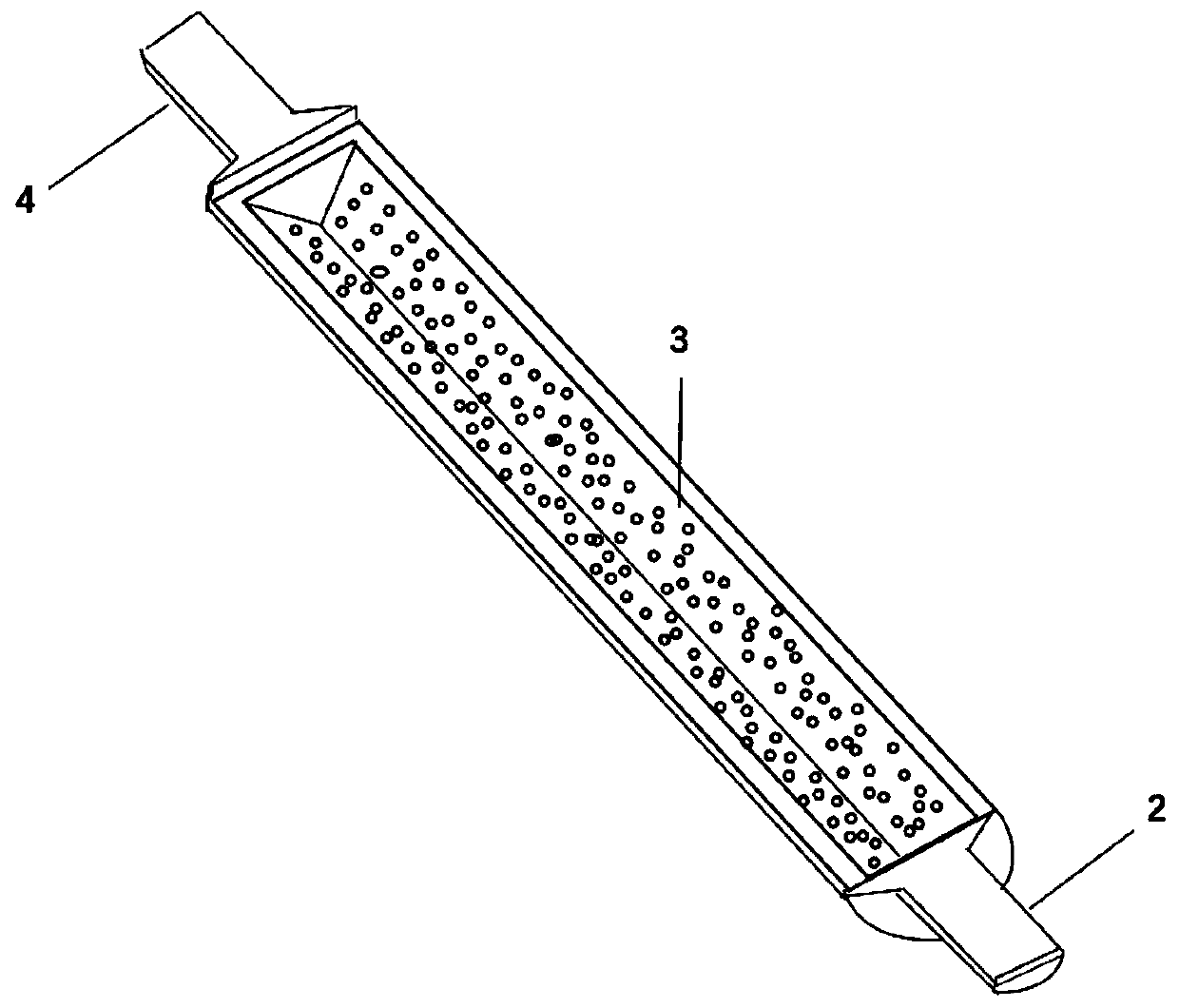

[0037] Taking a square filter channel in a particulate filter (DPF) as the research object, an observation device for simulating the visualization of DPF single channel and double-sided filtration is designed:

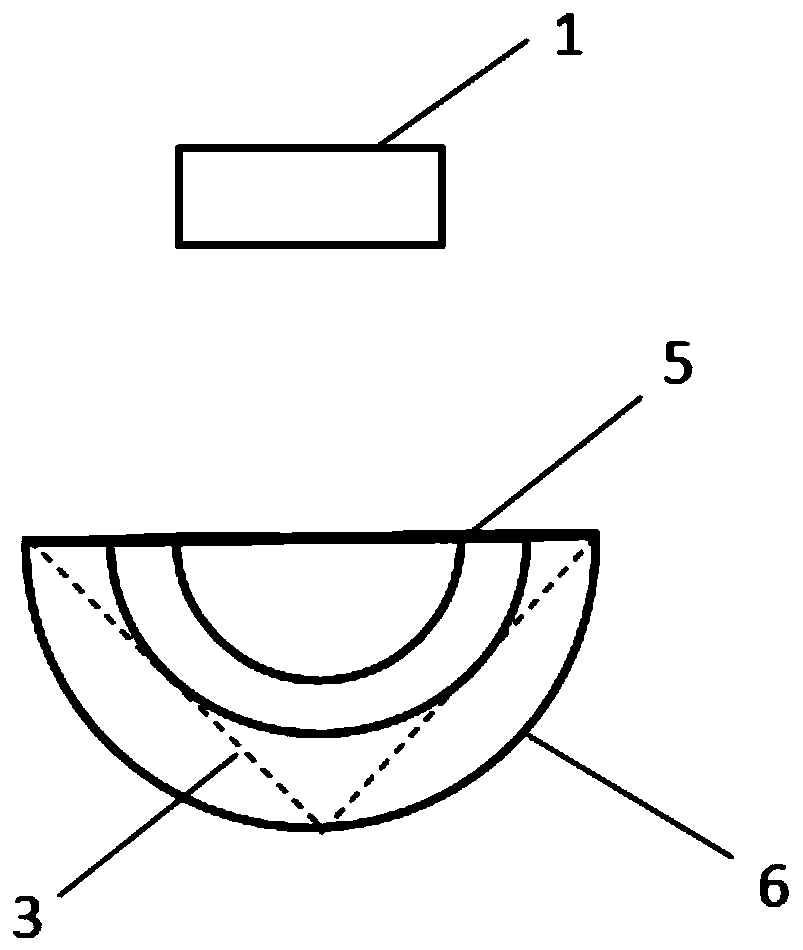

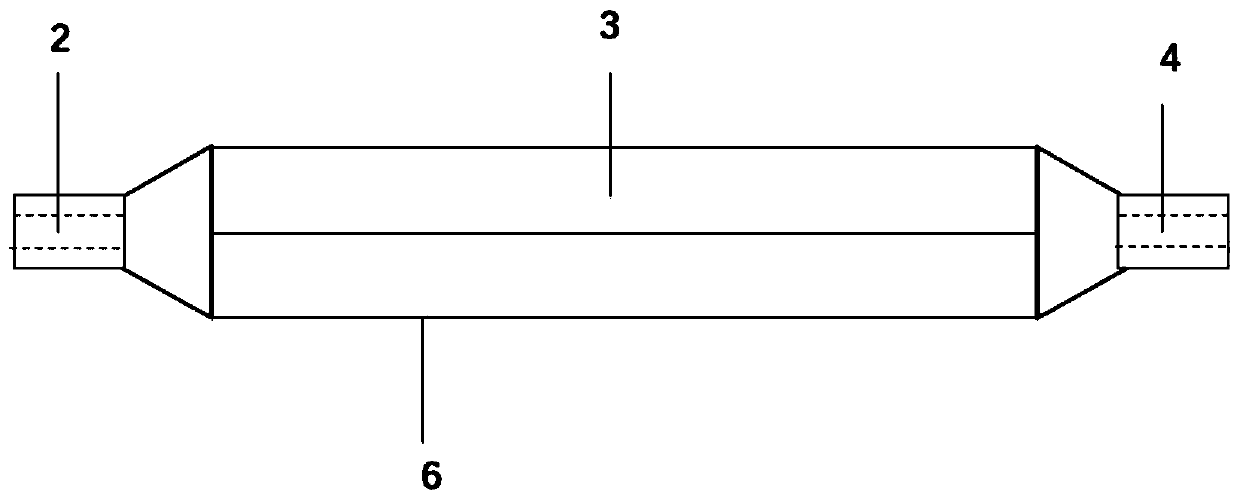

[0038] like Figure 1 to Figure 3 As shown, the actual filter channel cross-section is a square, its side length d=1mm, the designed filter channel 3 cross-section is an isosceles right triangle, the right angle side length is 10mm, and the filter channel 3 length is 100mm; filter inlet 2 and filter outlet 4 are all semicircular in section, with a diameter of 10mm; the transparent cover plate 5 is made of transparent glass, with a width of 20mm and a length of 100mm; the filter surface is filter paper, and the filter inlet 2, shell 6, filter outlet 4 and filter support surface Aluminum alloy is made by 3D printing.

[0039] When observing, the gas flow rate is controlled to be 1 / 10 of the gas flow rate in the actual filter, so that the Reynolds number is similar, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com