Drying oven and heat flow circulation control method

A drying box and box technology, which is applied in the direction of drying solid materials, drying chamber/container, drying gas arrangement, etc., can solve problems such as difficulty in removing water vapor in the cavity, temperature field difference that does not meet the requirements of the national standard, and slow heat flow circulation speed, etc. , to achieve the effect of simple, compact and ingenious structure, avoiding air residue and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

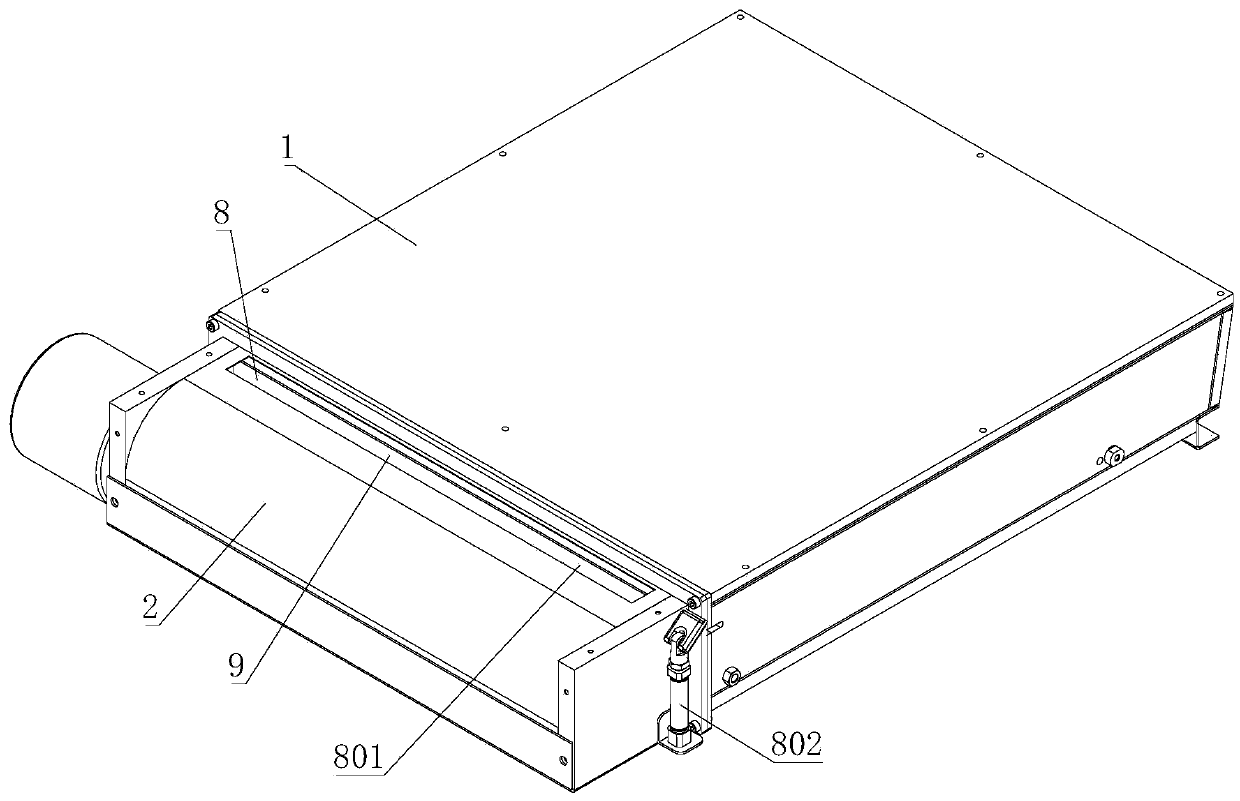

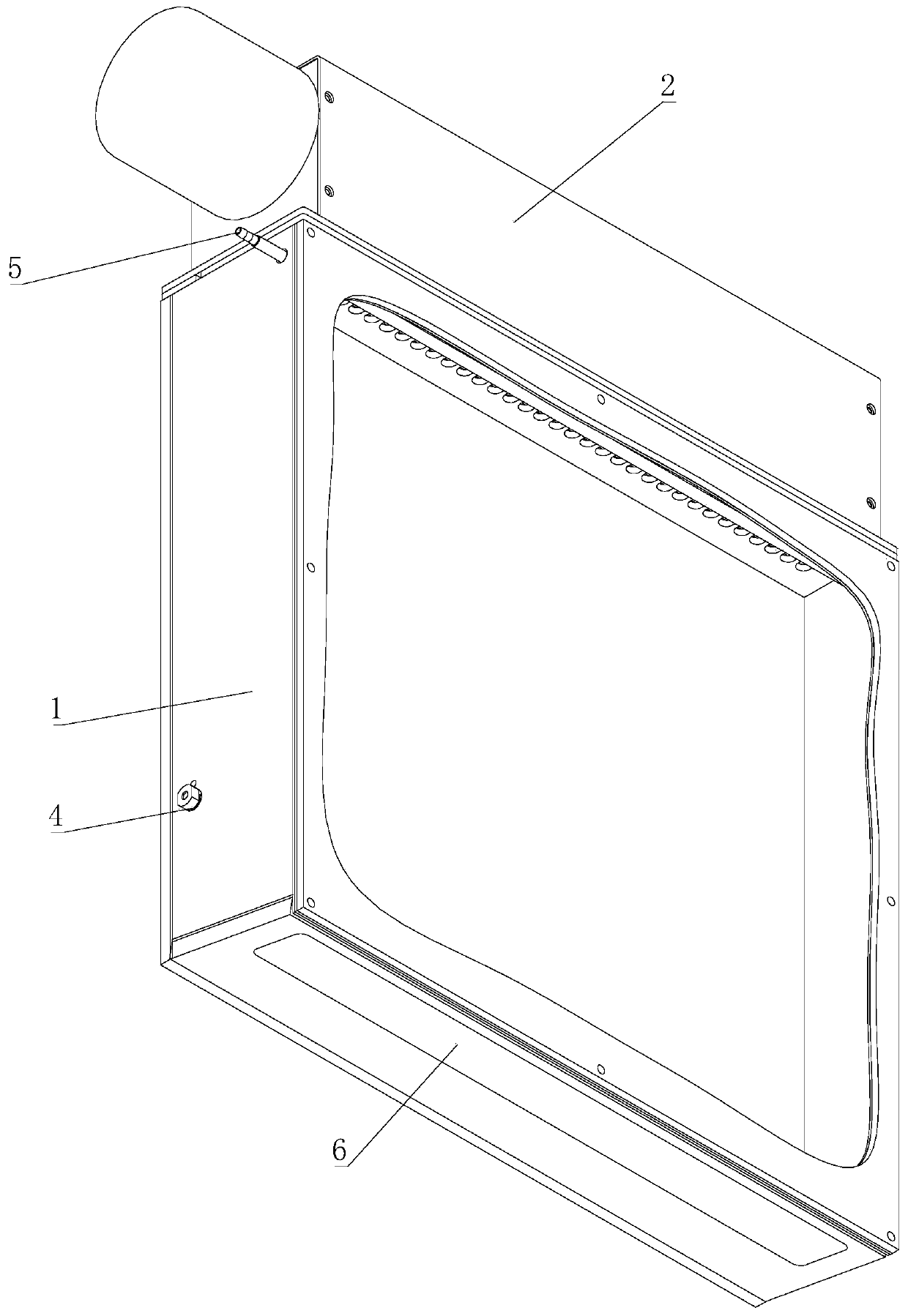

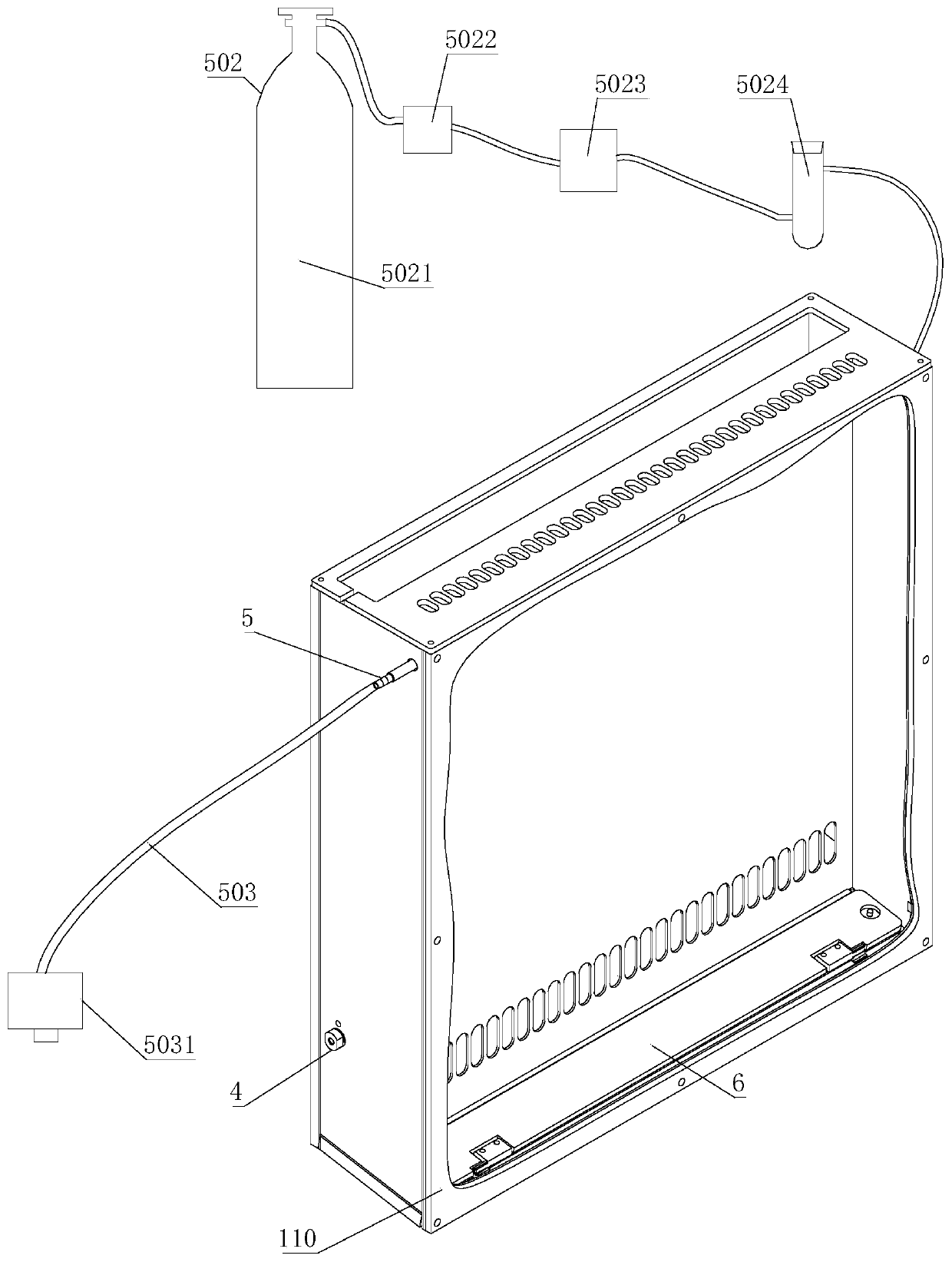

[0042] like Figure 1 to Figure 9 As shown, the drying box of this embodiment is used for drying operations in the moisture determination of samples (such as coal samples), and includes a box body 1 and a chamber formed by the box body 1. A partition 101 is arranged in the chamber for use in Because the chamber is divided into a first chamber 112 and a second chamber 113 arranged up and down; the first chamber 112 is used to dry the sample (that is, a drying chamber for placing a sample tray of a corresponding particle size sample), One end of the first chamber 112 is provided with a sampling door 6, and one end of the casing 1 opposite to the sampling door 6 is provided with a heating chamber 2, and the heating chamber 2 communicates with the first chamber 112 and the second chamber 113 respectively, specifically Specifically, the first chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com