Glue injecting device for unit glass curtain wall and glue injection method of glue injecting device

A technology of glass curtain wall and glue injection device, which is applied to the device, construction, coating and other directions of coating liquid on the surface, can solve the problems of inconvenient construction, waste of glue, waste, etc., so as to improve construction efficiency and prevent glue The effect of material solidification and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

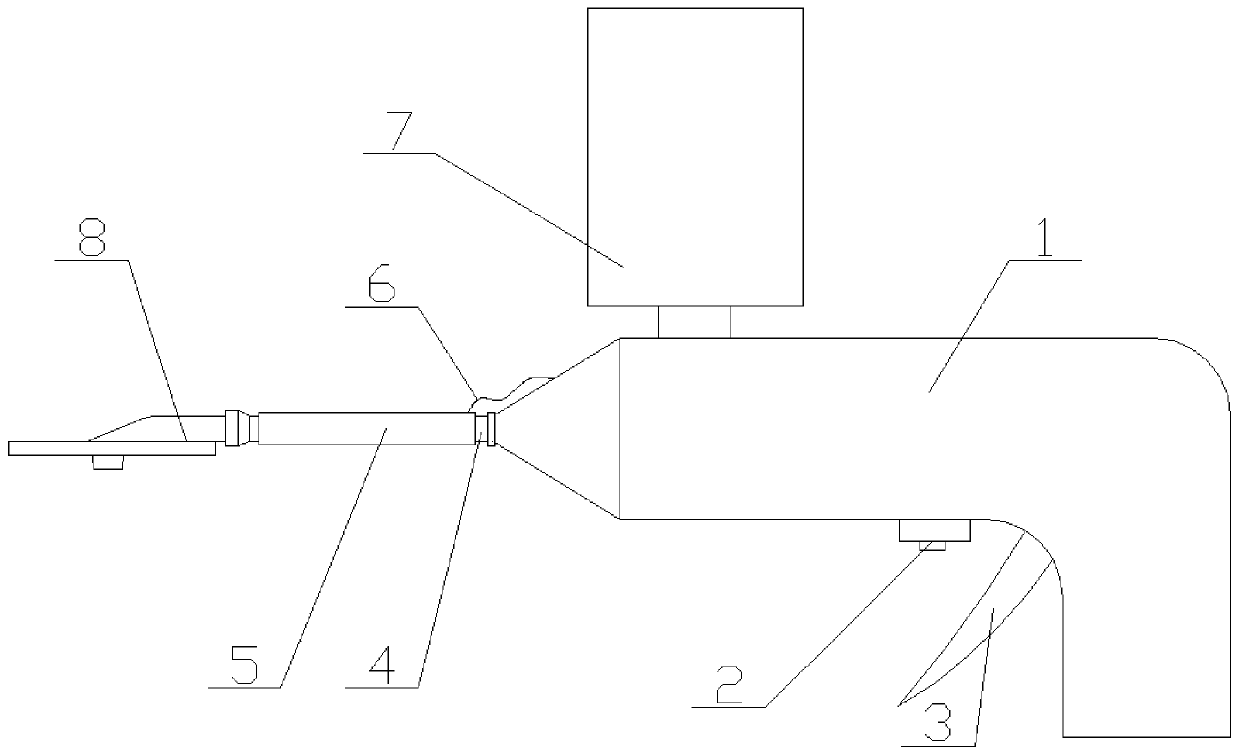

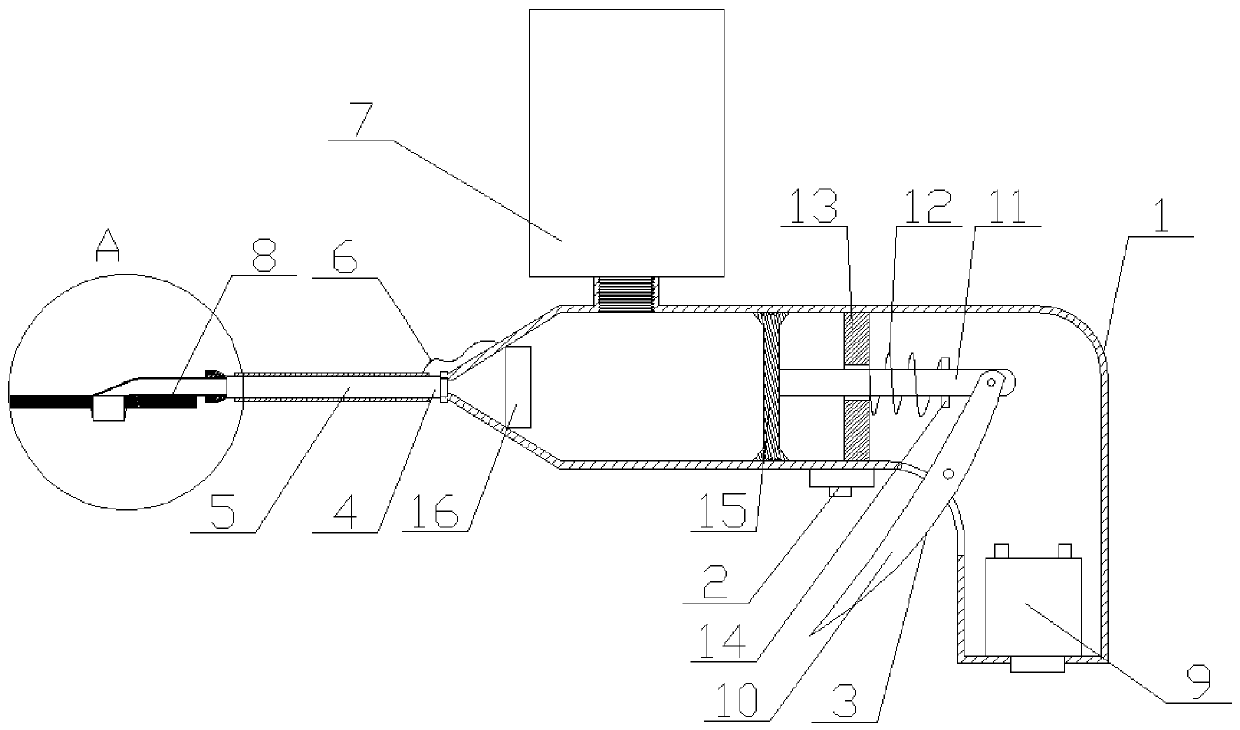

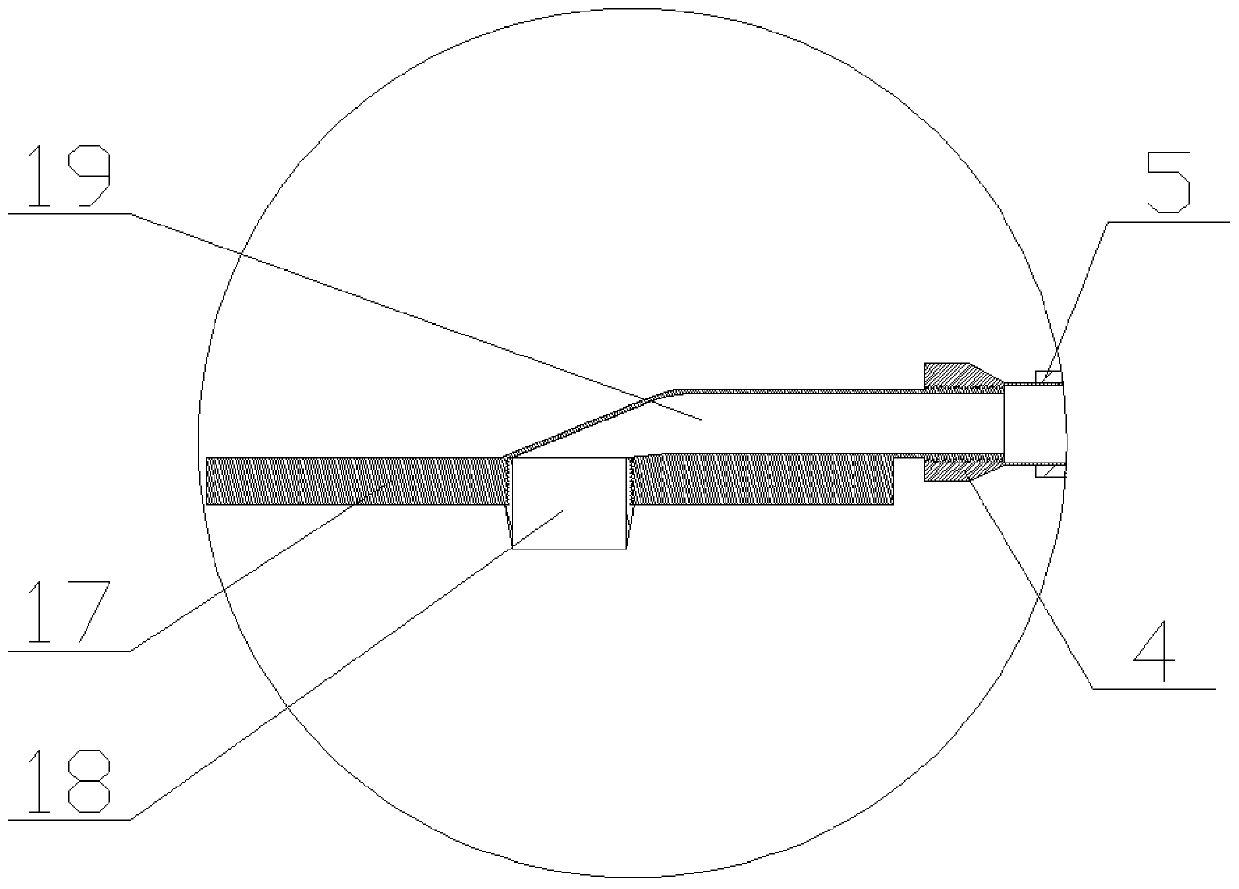

[0028] Such as Figure 1-Figure 3 with Figure 5 Shown: a unit glass curtain wall glue injection device, including an L-shaped glue injection gun body 1, the muzzle end of the glue injection gun body 1 is connected with a horizontally arranged glue injection tube 4 through threads, the glue injection tube 4 is a round tube, and the glue injection tube 4. The upper cover is provided with an electric heating sleeve 5, and the end of the injection pipe 4 far away from the injection gun body 1 is threadedly connected with the injection nozzle 8, and the top of the injection gun body 1 is connected with a storage mechanism 7 near the end of the muzzle. The glue storage mechanism 7 is a cylindrical glue storage bottle, which is connected to the glue injection gun body 1 through threads. The outer wall of the glue injection gun body 1 is provided with a power switch 2, and the glue injection gun body 1 is equipped with a glue injection driving mechanism. 3. A glue injection cavity i...

Embodiment 2

[0039] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the glue injection drive mechanism 3 includes a guide baffle 13 vertically arranged in the middle of the horizontal section of the glue injection gun body 1, a motor and a motor that is horizontally arranged on the glue injection gun body 1 Inside the fixed shaft, the middle part of the guide baffle 13 is provided with a guide hole, and the guide hole is provided with a horizontally arranged push rod 11, which is slidably connected with the guide hole, and the push rod 11 is close to the muzzle end of the glue injection gun body 1. One end is connected with a pusher piston 15, the outer diameter of the pusher piston 15 matches the inner diameter of the injection cavity, the fixed shaft is vertically arranged with the push rod 11, one end of the fixed shaft is fixedly connected with the glue injection gun body 1, and the fixed shaft The end is rotated to be provided with a cam 24,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com