Non-woven fabric needling machine

A technology for acupuncture machines and non-woven fabrics, which is applied in the directions of acupuncture machines, non-woven fabrics, textiles and paper making, etc., can solve problems such as affecting the compression of fibers, affecting the overall quality of non-woven fabrics, and shallow penetration. Acupuncture effect, overall quality improvement, reduced cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

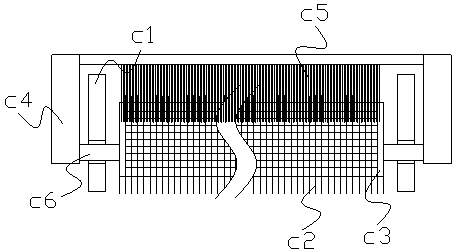

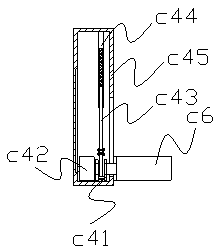

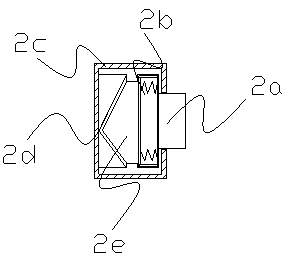

[0030] see Figure 1-Figure 11 , the specific embodiments of the present invention are as follows:

[0031] Its structure includes a horizontal frame 1, a body 2, a transmission box 3, a motor 4, and an acupuncture structure 5. The horizontal frame 1 is horizontally installed between the body 2 and welded together, and the transmission box 3 is horizontally installed on the horizontal frame 1. The motor 4 is mounted on the upper end of the transmission box 3 and is connected by a chain, and the acupuncture structure 5 is arranged below the transmission box 3 and is mechanically connected; the acupuncture structure 5 includes The lower buffer cylinder 51, the fixed acupuncture mechanism 52, the upper buffer cylinder 53, the connecting frame 54, and the driving rod 55, the lower buffer cylinder 51 is equidistantly installed on the lower end of the fixed acupuncture mechanism 52, and the upper buffer cylinder 53 is installed vertically On the upper end of the fixed acupuncture m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com