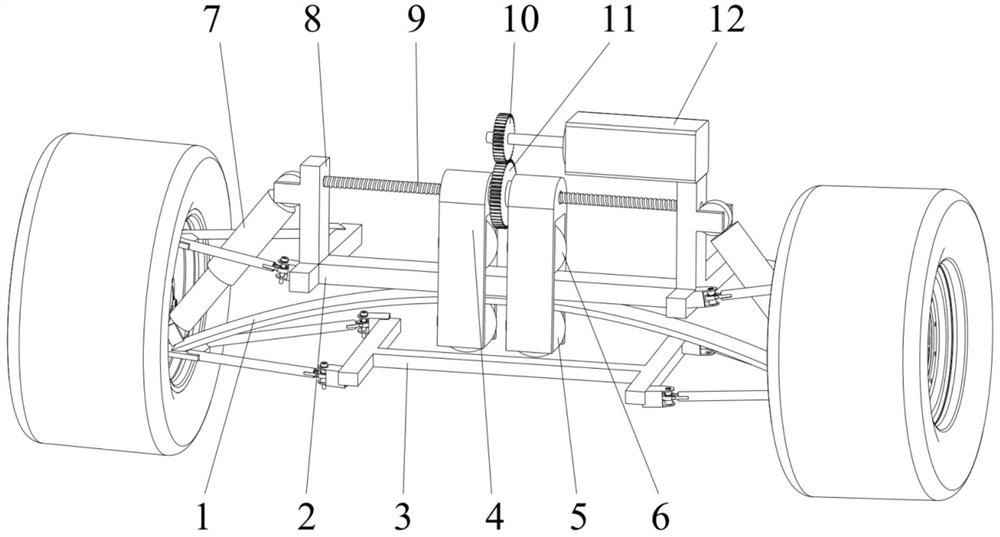

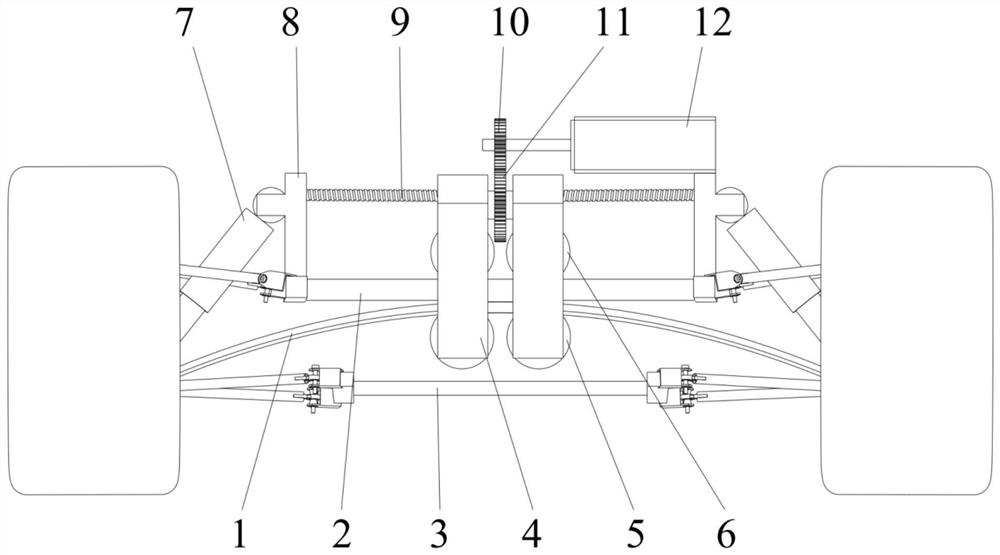

A vehicle transverse leaf spring suspension system with continuous stiffness adjustment

A leaf spring suspension, transverse technology, applied in the field of vehicle suspension system, can solve the problems of limited ability to improve ride comfort, expensive actuators, multi-energy, etc., to meet ride comfort requirements, and the control method is simple and efficient , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

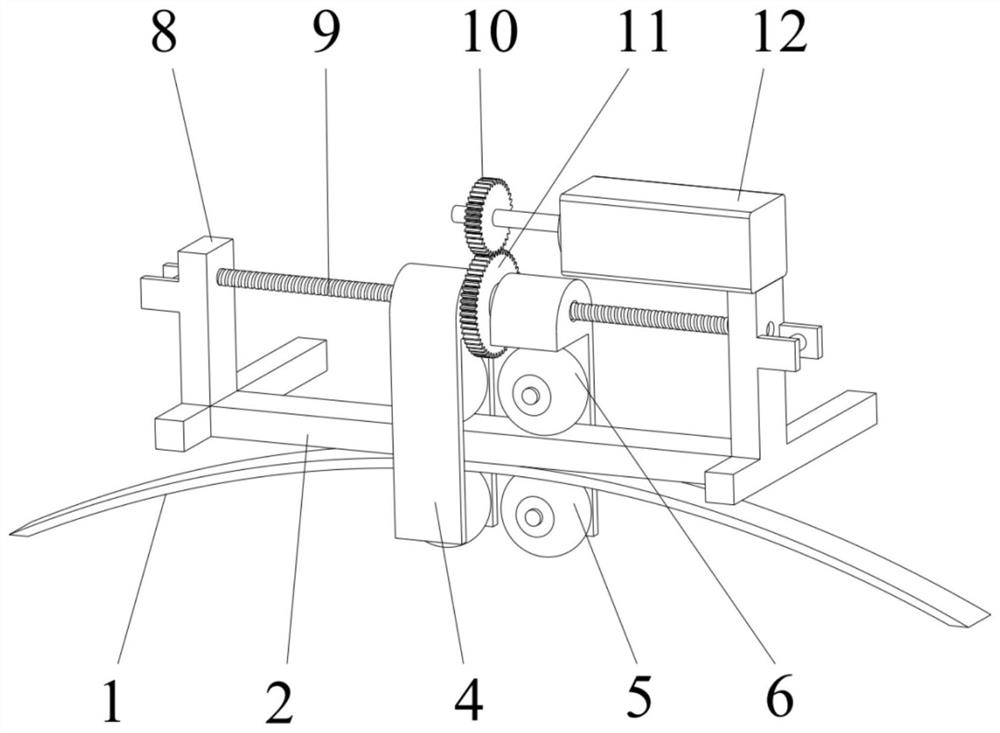

Method used

Image

Examples

Embodiment 1

[0059] A certain type of 7-seat SUV vehicle suspension system of the present invention is used.

[0060] The structural parameters of the suspension adjustment system are as follows: the elastic modulus of the transverse leaf spring is E=420GPa, the section moment of inertia I=5×10 -9 m 4 , The cantilever adjustment range is 550mm-750mm. According to formula (2), its stiffness adjustment range is 29800N / m-75700N / m. The lead of the bidirectional lead screw 9 is 2 mm, the number of teeth of the driving gear 10 is 19, the number of teeth of the driven gear 11 is 67, and the transmission ratio is 3.53. The power of the driving motor 12 is 400w, the rated torque is 1.27Nm, and the rated speed is 3000rpm.

[0061] Under the initial conditions, when only the driver is seated, the passenger mass is calculated as 75Kg, and the sprung mass m 1 It is 1385Kg. Suspension default initial stiffness K 1 It is 31150N / m, calculated according to the formula (2), the cantilever length of th...

Embodiment 2

[0068] Use certain type 12 MPV vehicle suspension system of the present invention.

[0069] The structural parameters of the suspension adjustment system are as follows: the elastic modulus of the transverse leaf spring is E=420GPa, the section moment of inertia I=1.37×10 -8 m 4 , The cantilever adjustment range is 400mm-750mm. According to formula (2), its stiffness adjustment range is 82000N / m-540000N / m. The lead of bidirectional lead screw 9 is 2 mm, the number of teeth of driving gear 10 is 17, the number of teeth of driven gear 11 is 73, and transmission ratio is 4.29. The driving motor 12 has a power of 750w, a rated torque of 2.39Nm, and a rated speed of 3000rpm.

[0070] Under the initial conditions, when only the driver is seated, the passenger mass is calculated as 75Kg, and the sprung mass m 1 It is 1695Kg. Suspension default initial stiffness K 1 is 88900N / m, calculated according to formula (2), the cantilever length of leaf spring is 730mm at this time. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com