Intelligent digital display torque wrench circuit control system and method

A torque wrench and circuit control technology, applied to wrenches, manufacturing tools, screwdrivers, etc., can solve the problems of no rechargeable battery charge and discharge protection, data disorder, large power consumption, etc., to achieve tool space positioning and over-discharge protection , Guarantee the effect of data loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] As introduced in the background technology, in the prior art, there are large power consumption of the wrench circuit control system, easy damage of in-line charging, poor information interaction, easy loss of data, and inability to upload data in real time outdoors. In order to solve the above technical problems, This embodiment provides an intelligent digital display torque wrench circuit control system.

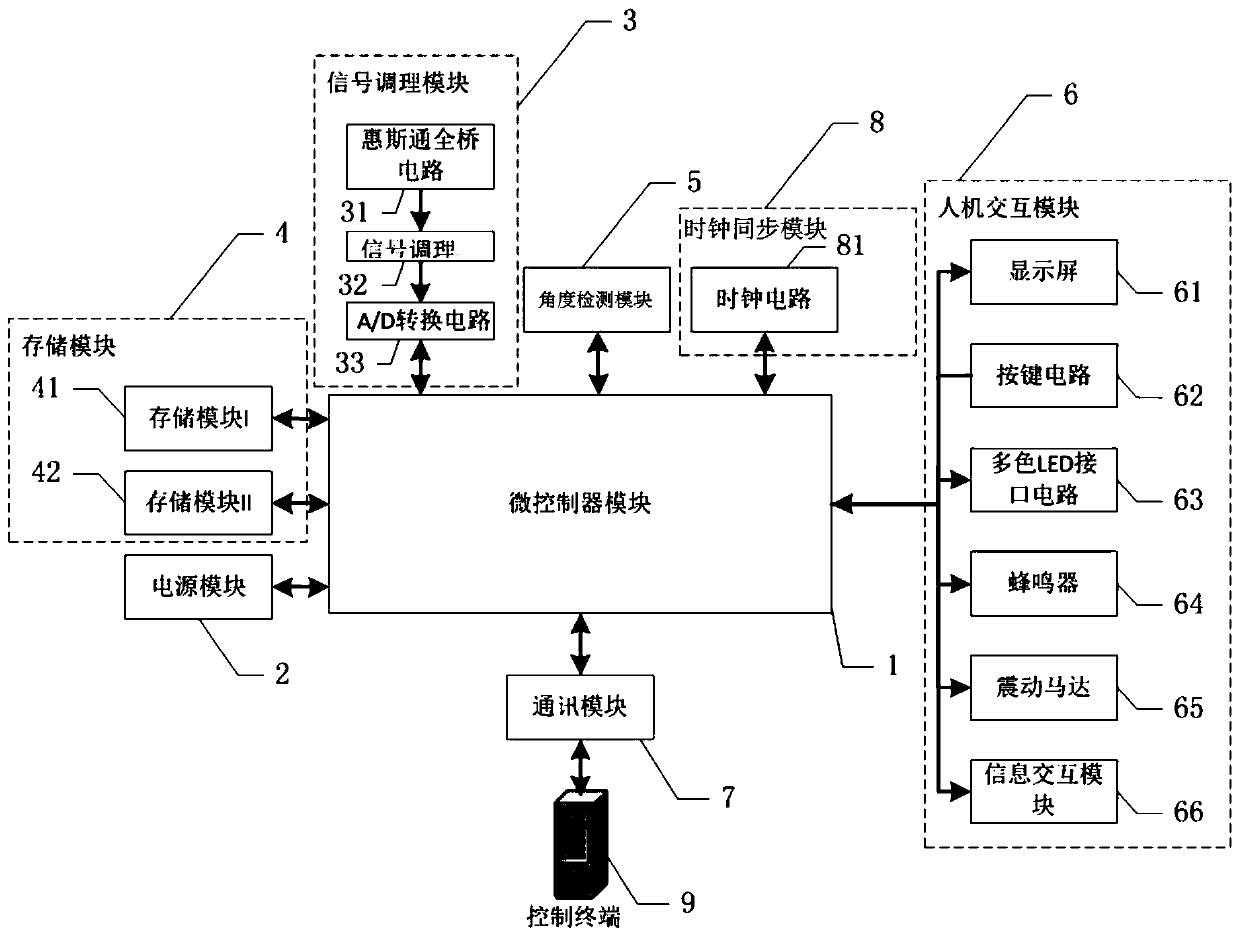

[0045] figure 1 It is a schematic diagram of the overall structure of the intelligent digital display torque wrench circuit control system involved in this embodiment. like figure 1 As shown, the control system includes a microcontroller module 1 , a power module 2 , a signal conditioning module 3 , a storage module 4 , an angle detection module 5 , a human-computer interaction module 6 , a communication module 7 , a clock synchronization module 8 and a control terminal 9 .

[0046] Specifically, the microcontroller module 1 is composed of a microcontroller and pe...

Embodiment 2

[0076] Taking the tightening of a fastener of a station component as an example, the steps of the circuit control method for an intelligent digital display torque wrench involved in this embodiment include:

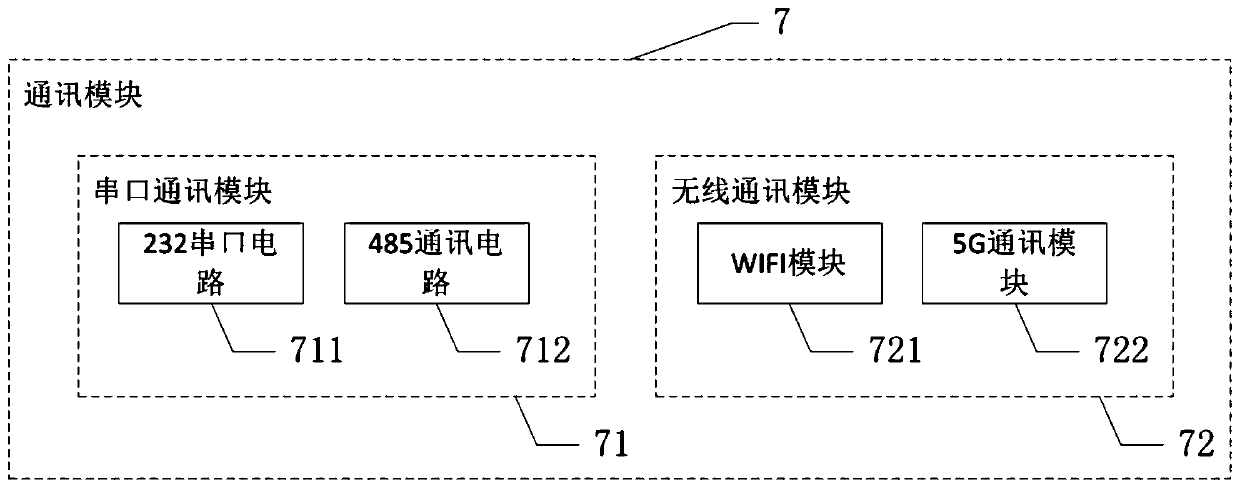

[0077] S101, the PC terminal 91 performs data transmission through the WIFI module 721. When the on-site WIFI is seriously shielded, it automatically switches to the 5G communication module 722 for communication, and the PC terminal 91 sends the wrench tightening qualified interval and angle range to the wrench microcontroller module , through the camera module of the information interaction module 66, the face recognition of the wrench tightening operator is performed, and the station parts are photographed, identified and uploaded, and at the same time, the information of the station parts is scanned and uploaded through the scanning module to ensure that the wrench tightens the station parts correctly. Realize wrench tightening positioning.

[0078] S102. During the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com