Product with slide fastener and method for manufacturing product with slide fastener

A manufacturing method and zipper technology, applied in the field of products with zipper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

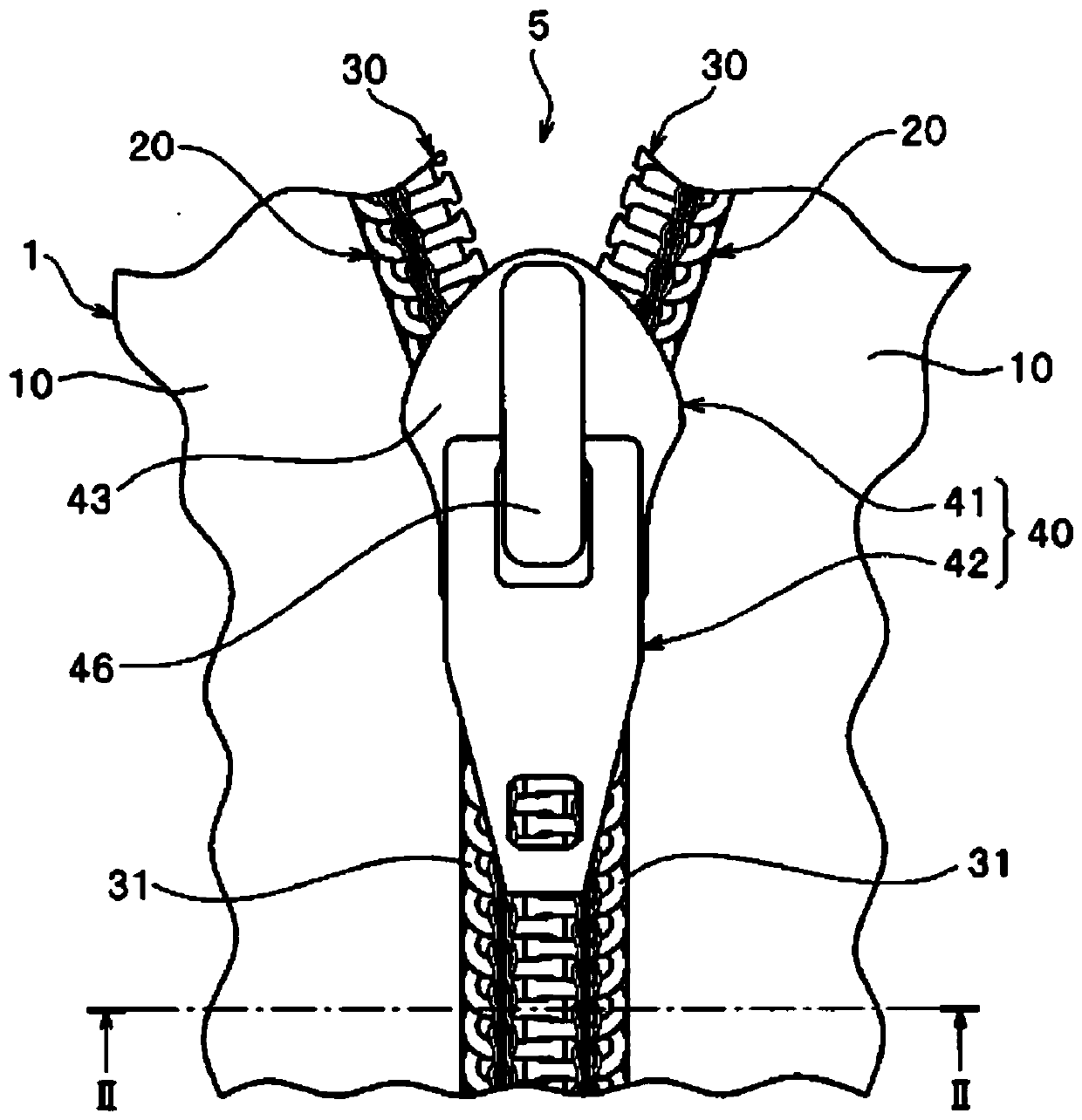

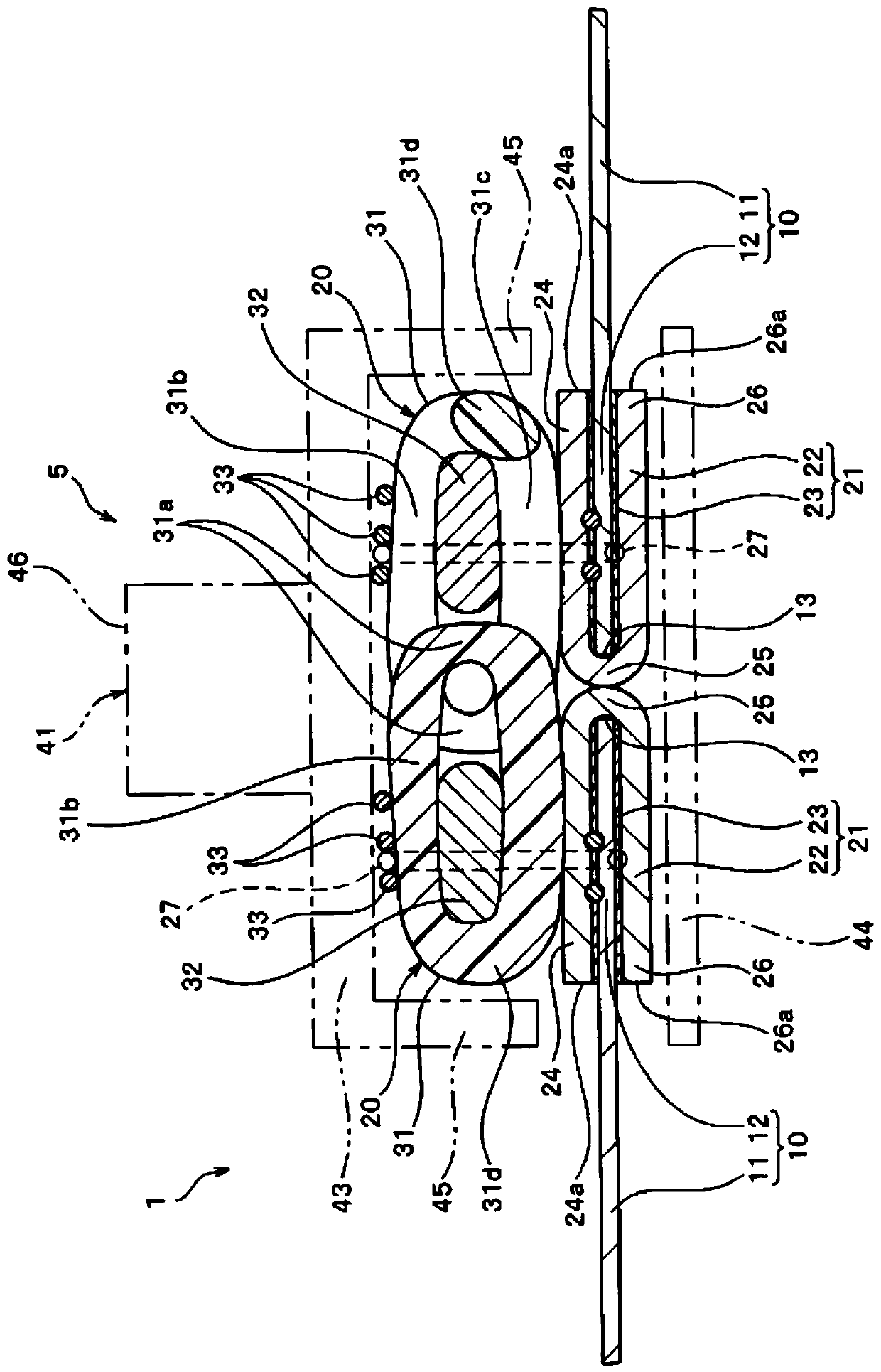

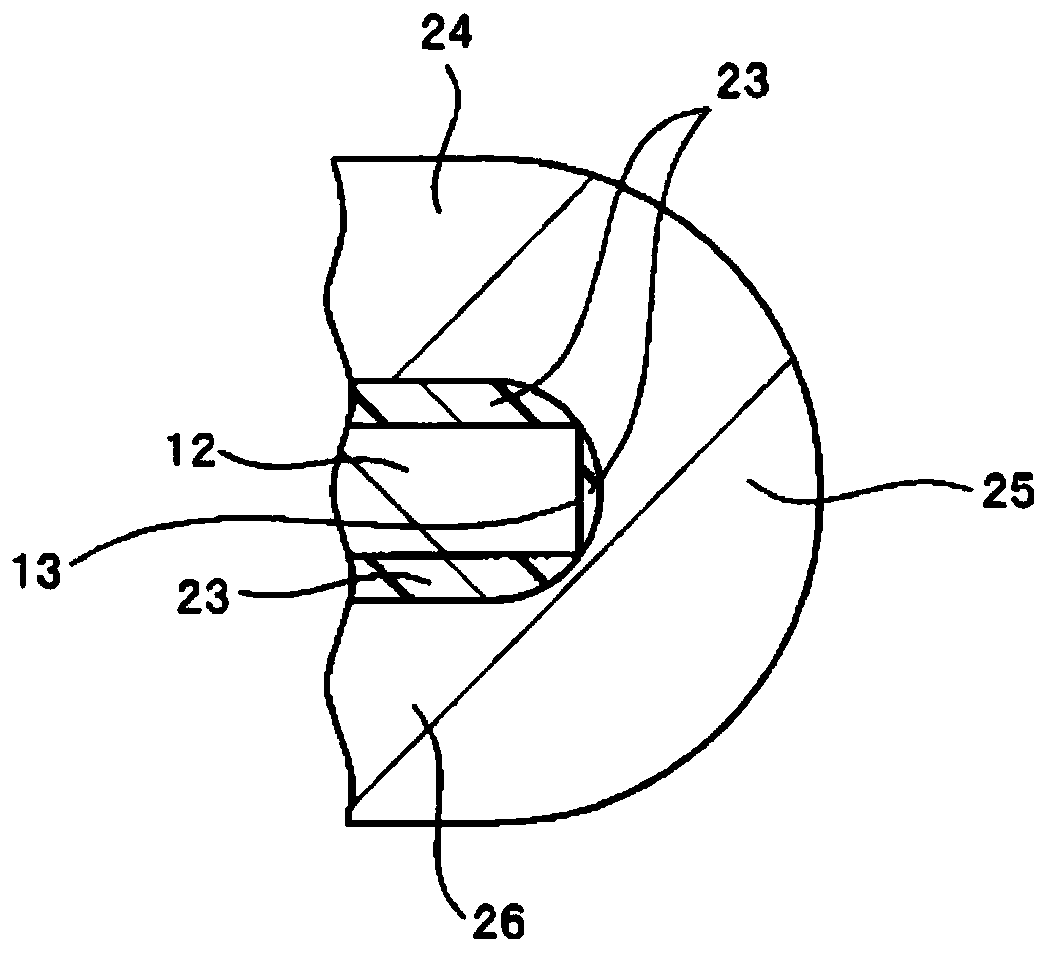

[0113] figure 1 It is an enlarged schematic diagram schematically showing an enlarged main part of the product with a zipper according to the first embodiment. figure 2 Yes figure 1 The sectional view of line II-II shown, image 3 is enlarged figure 2 The enlarged cross-sectional view of the main part of the local. also, Figure 4 and Figure 5 It is a plan view and cross-sectional view which show a pair of fastener stringers concerning this Example 1.

[0114] In addition, in the following description, the front-back direction refers to the longitudinal direction of the fastener stringer (or belt member) parallel to the sliding direction of the slider. The direction of the front is defined as the front, and the direction of sliding so as to separate the left and right element rows is defined as the rear.

[0115] The left-right direction refers to the width direction of the zipper fastener tape or the width direction of the fabric used as the zipper installation pa...

Embodiment 2

[0188] Figure 10 It is a sectional view which only partially and schematically shows the fastener stringer of the product with the fastener which concerns on this Example 2.

[0189] The fastener stringer 20 of the above-mentioned Example 1 is formed by sewing and fixing the fastener element 31 to the 1st tape piece part 24 of the tape member 21 using the element sewing thread 33. As shown in FIG. On the other hand, while forming the belt main body 62 of the belt member 61 by weaving, the fastener stringer 60 of the present embodiment 2 is woven as the fastener elements 71 and fixed to the so-called weaving belt main body 62. In-type zipper stringer tape 60 is formed.

[0190] That is, the fastener stringer 60 of this Example 2 has the several fastener element 71 of the continuous shape which was woven into the tape main body 62 of the tape member 61 and this tape member 61, and was fixed. Furthermore, the belt member 61 of the second embodiment has a woven belt body 62 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com