Automatic evaluation machine for engine assembly and disassembly

An engine and automatic technology, applied in educational appliances, instruments, teaching aids and other directions, can solve the problems of difficult technical personnel screening, time-consuming engine disassembly and assembly, and large labor occupation, so as to ensure fair assessment and eliminate multiple interference factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

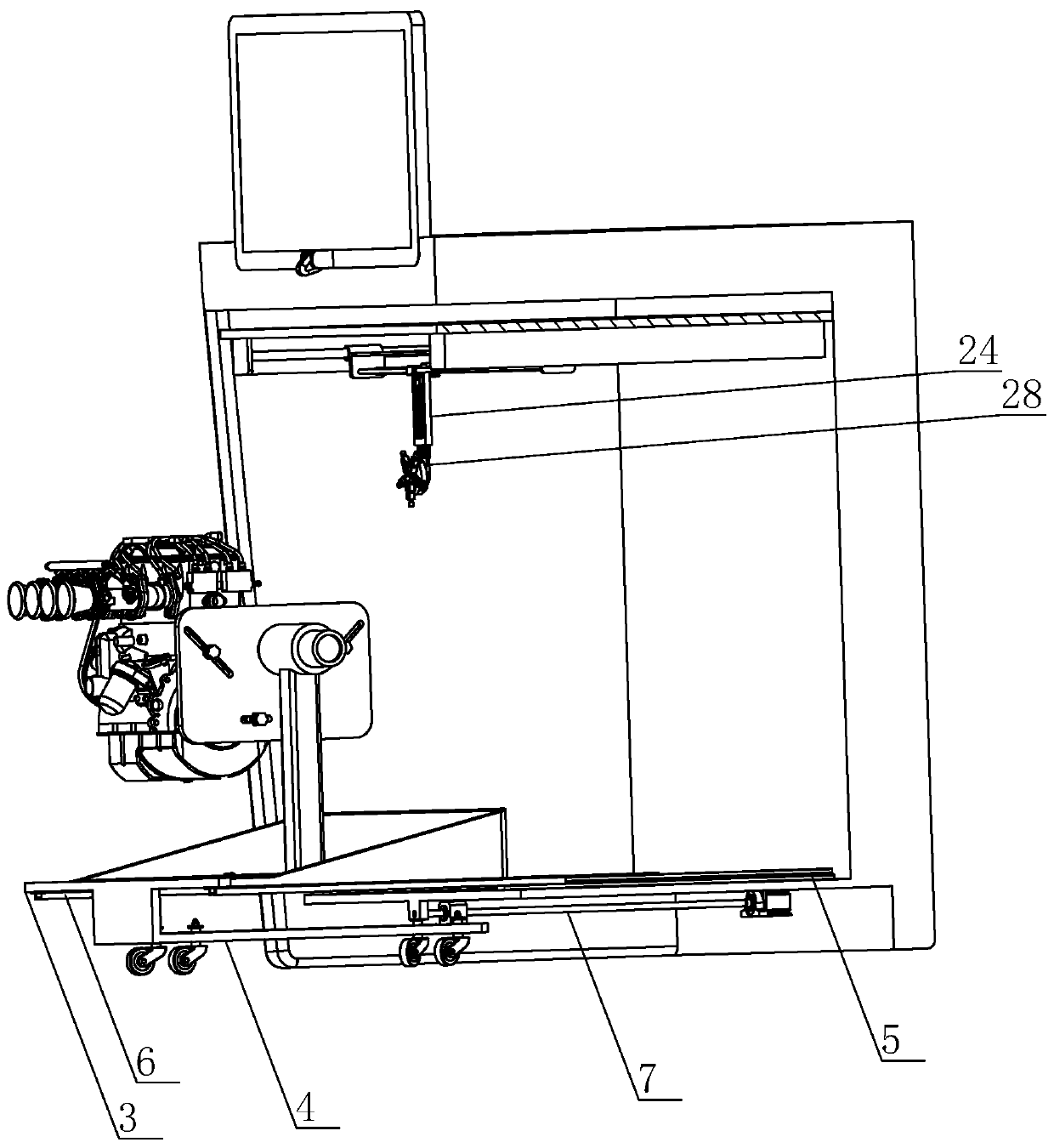

[0055] Embodiment: Automatic evaluation machine for engine disassembly

[0056] The disassembly and assembly of the engine is the prerequisite for maintenance and overhaul of the engine. In particular, restoring the engine to the original installation level as much as possible, avoiding wear and ensuring sealing is the most important core skill for auto repair and auto builders. Whether it is the assessment of trainees by training institutions, the assessment of employees by enterprises, and the assessment of recruits by enterprises, it is necessary to conduct standardized evaluations on disassembly and assembly of engines. However, the disassembly and assembly of the engine often takes a long time, and there are many technical points that need to be assessed. If you rely on people to watch, not only two or three people will occupy at least one examiner for the disassembly and assembly, which is very labor-intensive and labor-intensive. Due to the different standards and leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com