Underwater sampling device for shallow water area

A sampling device and shallow water area technology, applied in the field of underwater detection, can solve the problem of a single underwater sampling module, etc., and achieve the effect of simple structure, easy maintenance, installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

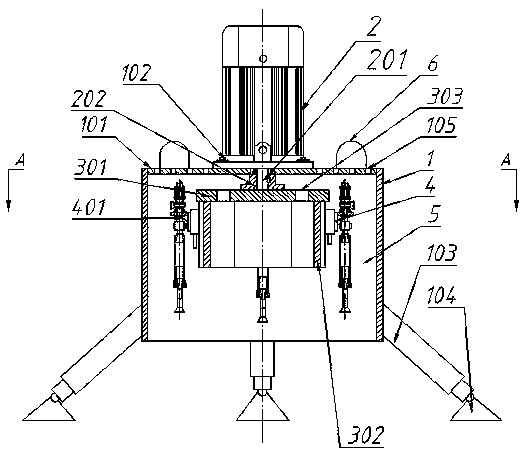

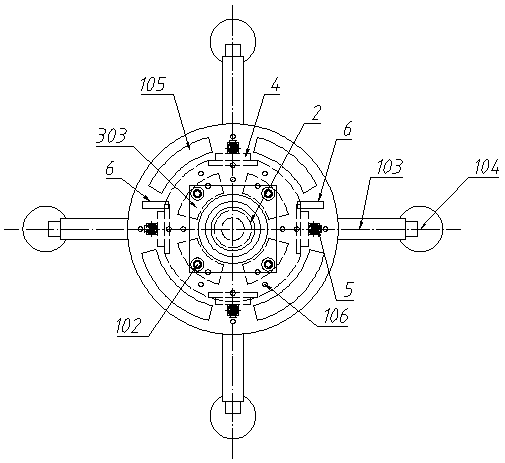

[0040] This embodiment is mainly used for underwater sampling work of lakes, such as Figure 1-3 As shown, an underwater sampling device used in shallow water areas includes an installation cylinder 1, and a rotating motor 2 is installed on the top plate 101 of the installation cylinder 1 through bolts 102, and the output shaft 201 of the rotating motor 2 passes through The top plate 101 is connected to the top cover 301 of the rotating cylinder 3; the bottom of the top cover 301 is provided with four motor mounting plates 302, and each of the motor mounting plates 302 is fixedly equipped with a linear motor 4, and the The linear motor 4 is equipped with a sampler 5 through a bracket 401; on the top plate 101 of the installation cylinder 1, there are also two hydraulic boxes 6 that provide power for the hydraulic telescopic rod 103, and the four hydraulic telescopic rods 103 are fixedly installed Below the outside of the cylinder wall of the installation cylinder 1, the four h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com