Wind tunnel helium reuse device

A technology of helium and wind tunnel, which is applied in the field of wind tunnel testing, can solve the problems of high cost of use and low efficiency of containers, and achieve the effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

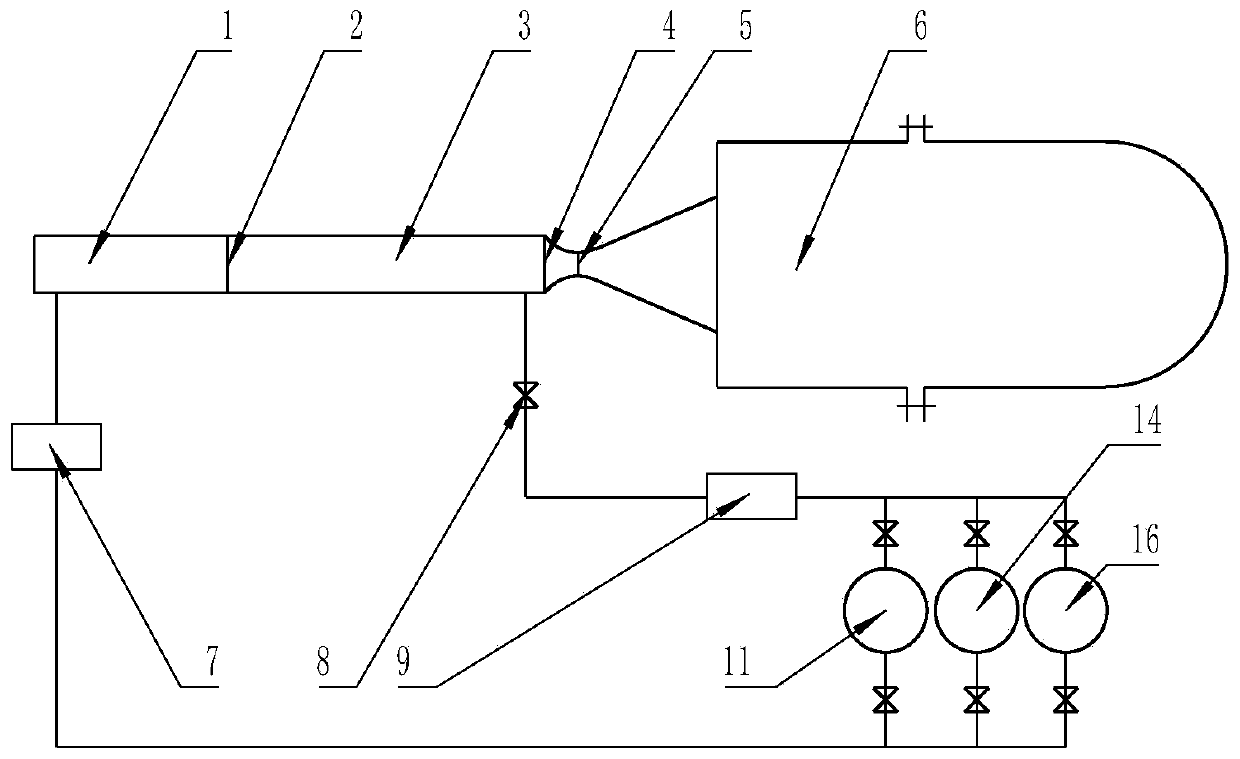

Embodiment 1

[0039] The specific implementation process of this embodiment is as follows:

[0040] a. Gas storage tank I11 stores helium with a purity of 99.999%, gas storage tank II14 stores helium with a purity of 98%, and gas storage tank III16 stores helium with a purity of 90%;

[0041] b. According to the requirements of the required driving gas, compare with the storage purity of gas storage tank I11, gas storage tank II14 and gas storage tank III16, and select the gas storage tank with the closest storage purity to provide driving gas; if the required driving gas If the purity of the gas is the same as the storage purity of the gas storage tank, select the corresponding gas storage tank to provide the driving gas; if the required driving gas purity is slightly higher than the storage purity of the gas storage tank, calculate the required helium and Fill the high-pressure section 1 with the required helium; if the purity of the required driving gas is slightly lower than the storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com