Assembled shear wall structure and construction method

A shear wall and prefabricated technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficulty in ensuring the construction quality of prefabricated integral shear wall structures, lack of multiple anti-seismic measures, and poor structural integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

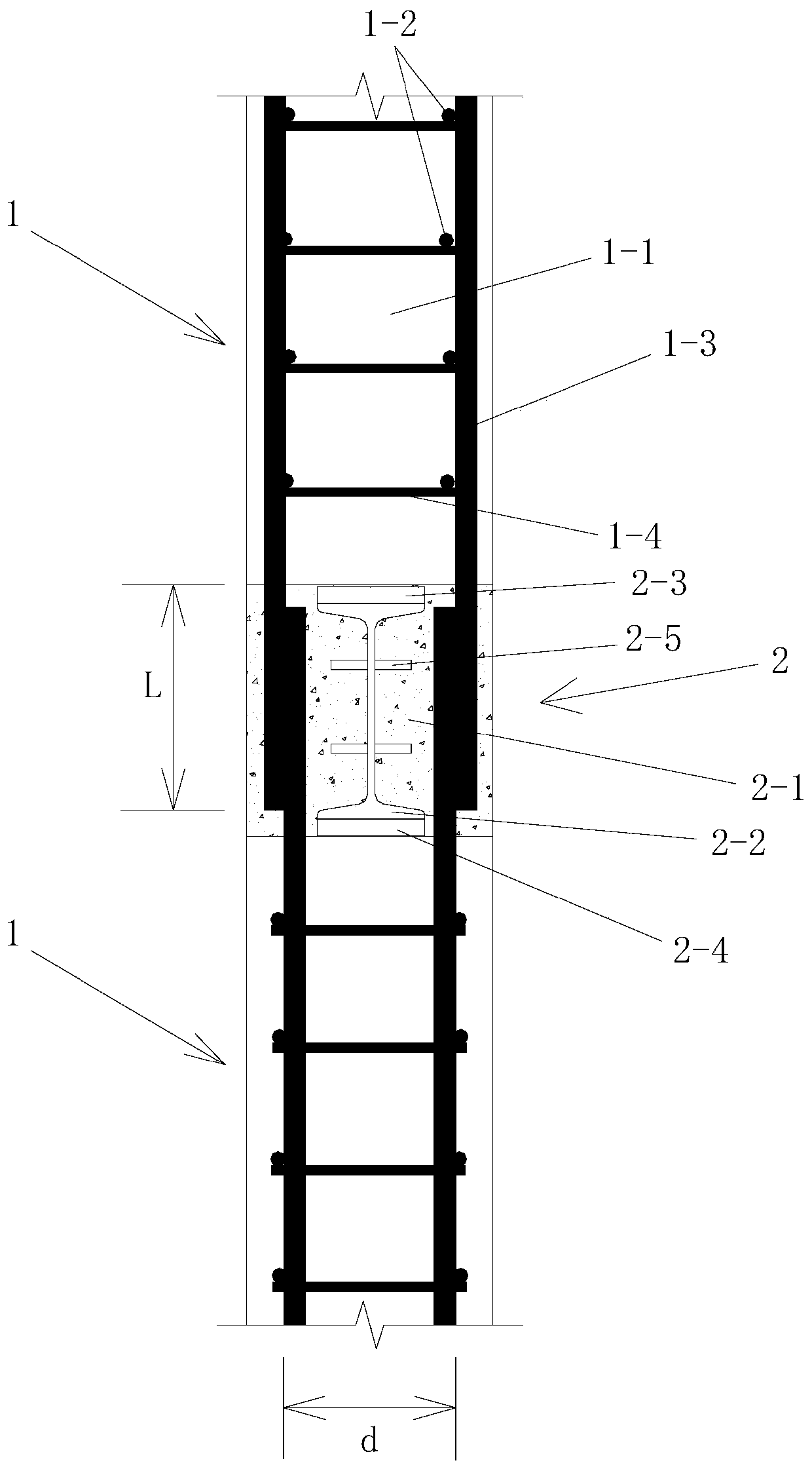

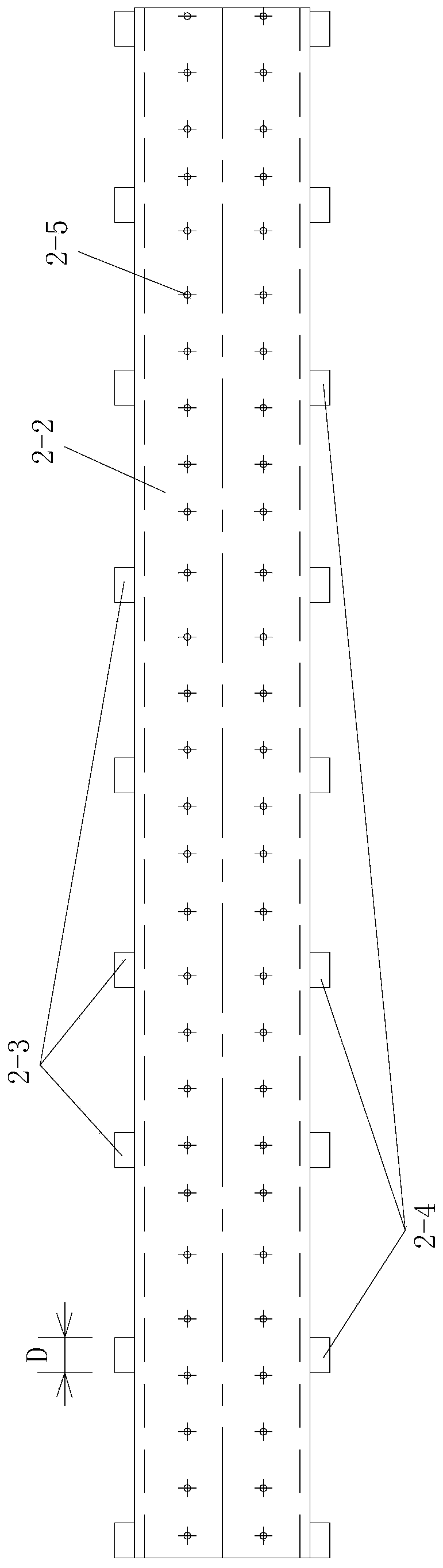

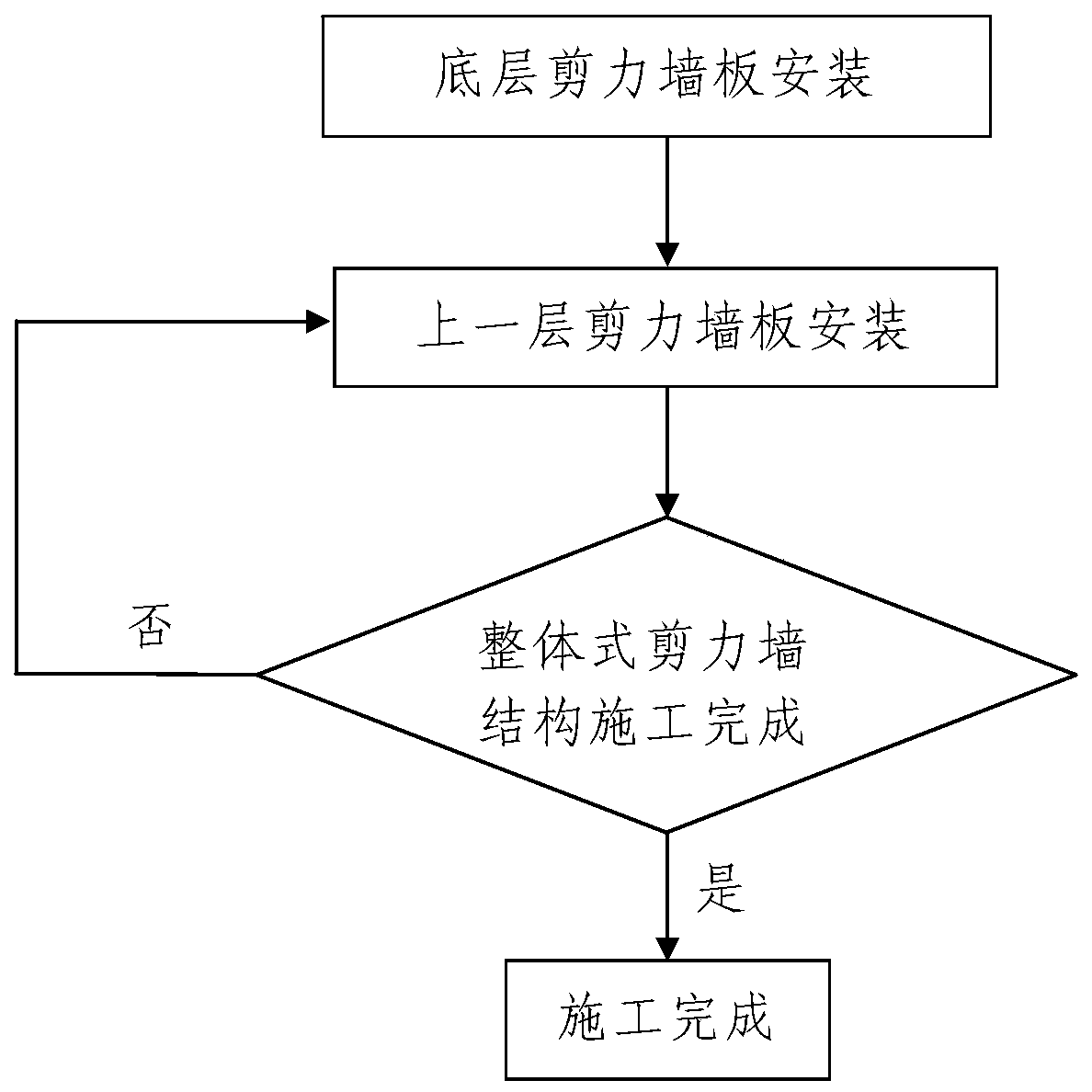

[0051] Such as figure 1 A prefabricated shear wall structure shown includes an integral shear wall structure connected by multi-layer shear wall panels arranged from top to bottom. The structures of the multi-layer shear wall panels are all the same and their are all arranged on the same vertical plane, the thickness of the multi-layer shear wall panels is the same, and the integral shear wall structure is a rectangular wall;

[0052] The shear wall panels of each layer are arranged vertically and are a prefabricated shear wall 1, and each of the prefabricated shear walls 1 is a rectangular wall arranged horizontally; each of the prefabricated shear walls The force walls 1 each include a concrete wall 1-1 and an internal support frame poured in the concrete wall 1-1; the internal support frame includes two symmetrically arranged vertical steel skeletons on the left and right, and the two vertical steel bars The skeletons are arranged in parallel and both are arranged along th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com