Method for subjecting acetylene and ketone compound to addition reaction

A ketone compound, addition reaction technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of large reaction volume, high cost, potential safety hazards, etc., to reduce the amount of acetylene, improve Effectiveness of Utilization, Increased Security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]

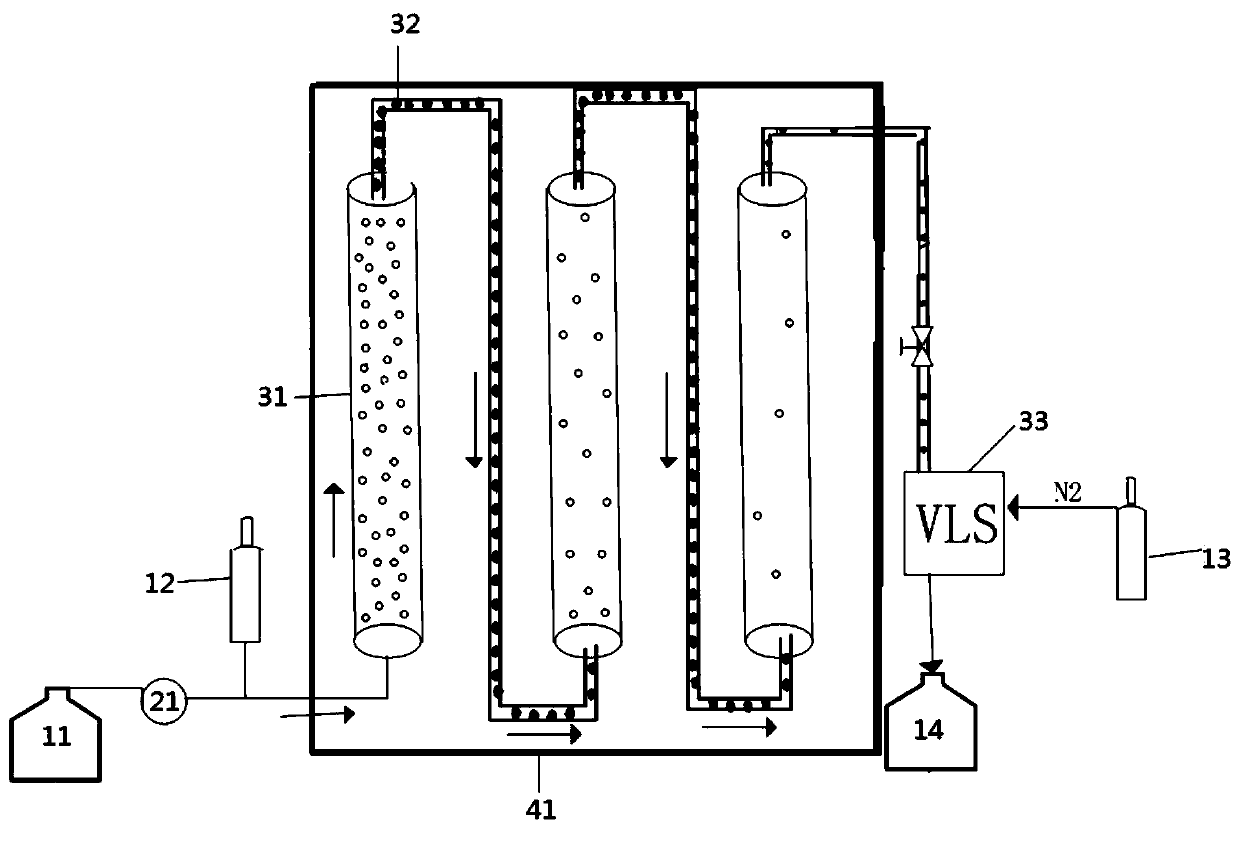

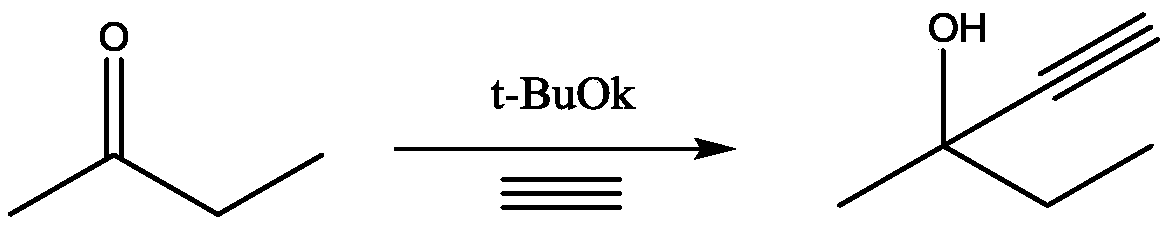

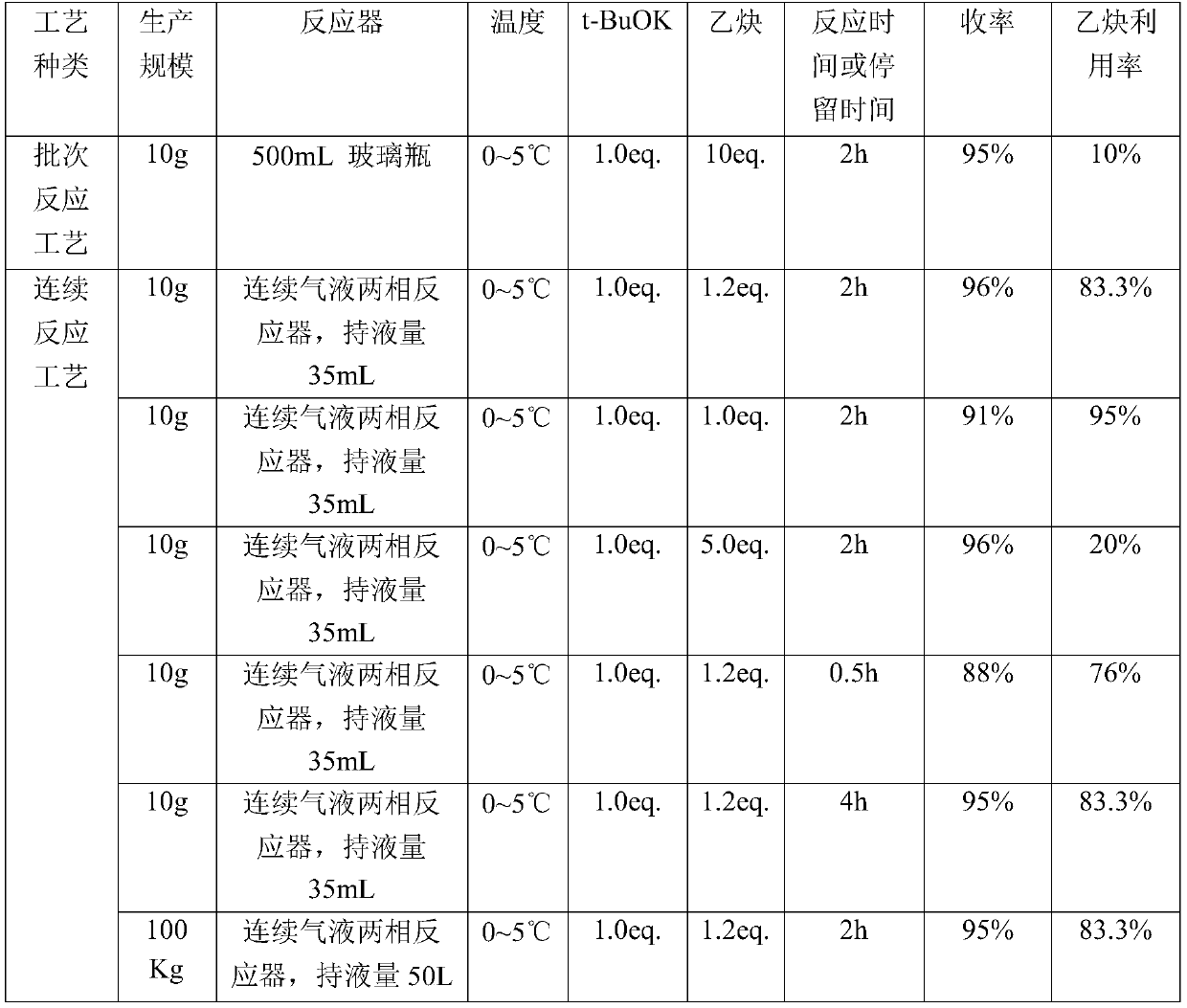

[0032] According to the above reaction formula, using figure 1 The shown device (continuous reaction device) and batch reaction process were reacted, and the specific parameters and results were shown in Table 1.

[0033] The raw material ketone and potassium tert-butoxide are dissolved in tetrahydrofuran of 10 times the volume of the raw material ketone, and the formed solution is called SM solution. Connect the SM solution to the feed pump in the reaction device. The temperature of the reaction apparatus was adjusted to the specified temperature. According to the size of the reactor and the required reaction time, calculate the SM solution feed rate. Based on the SM solution feed rate, and the required acetylene equivalents, calculate the acetylene feed rate. Simultaneously turn on the SM solution feeding pump and acetylene cylinder, and simultaneously feed into the reaction device according to the set flow rate. Take samples at the sampling point at the outl...

Embodiment 2

[0037]

[0038] According to the above reaction formula, using figure 1 The device shown was used for the reaction. For the steps, refer to Example 1. The specific parameters and results are shown in Table 2.

[0039] Table 2

[0040]

Embodiment 3

[0042]

[0043] According to the above reaction formula, using figure 1 The device shown was used for the reaction. For the steps, refer to Example 1. The specific parameters and results are shown in Table 3.

[0044] table 3

[0045]

[0046]

[0047] The above examples illustrate that this reaction can be successfully applied to the scale-up production of more than 100Kg level, not only has no scale-up effect, but also the process is safe and reliable. The direct application of acetylene gas in production-scale synthesis has been successfully achieved. In addition, compared with the batch process, the utilization rate of acetylene is greatly improved, further saving costs and improving process safety.

[0048] From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieved the following technical effects:

[0049] 1) The small size of the reactor can effectively avoid the accumulation of a large amount of ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com