Foliar fertilizer for preventing falling-off and premature senescence of cotton buds and bolls and preparation method thereof

An anti-shedding, foliar fertilizer technology, applied in the directions of nitrogen fertilizer, magnesium fertilizer, application, etc., can solve the problems of falling bolls, falling peach, low yield, etc., to increase the weight of a single boll, easy to harvest, and promote pollination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

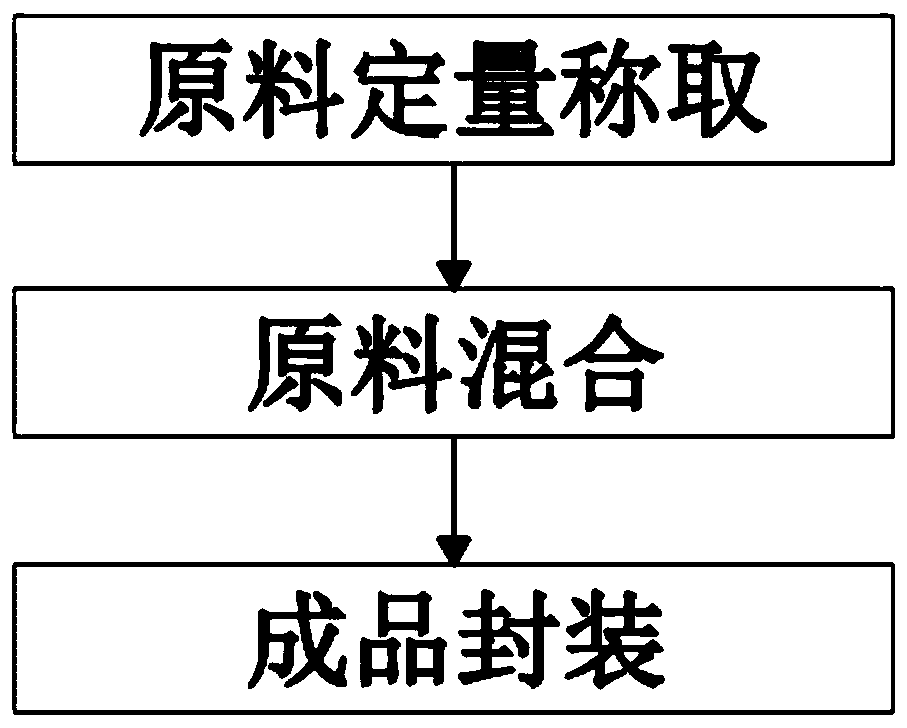

[0025] A method for preparing a foliage fertilizer for preventing cotton buds from shedding and preventing premature aging. The specific preparation steps of the method for preparing the foliage fertilizer for preventing cotton buds from falling off and preventing premature aging are as follows:

[0026] S1: Quantitative weighing of raw materials: Weigh amino acids, calcium, magnesium, boron, nitrogen, auxin and ethanol solutions according to mass specific gravity, and place various raw materials in storage tanks;

[0027] S2: Raw material mixing: Add amino acid, calcium, magnesium, boron, nitrogen, and auxin in step S1 to the ethanol solution in sequence, and mix the amino acid, calcium, magnesium, boron, nitrogen, auxin with the ethanol solution, and the raw materials are mixed using Mixing with a mixer, and the mixing temperature is 20-26 degrees Celsius, and the mixing time is 10-20 minutes to obtain the finished product;

[0028] S3: Encapsulation of the finished product:...

Embodiment 1

[0030] The specific preparation steps of the preparation method of the foliage fertilizer for cotton bud boll anti-shedding and anti-premature aging are as follows:

[0031] S1: Quantitative weighing of raw materials: Weigh amino acid, calcium, magnesium, boron, nitrogen, auxin and ethanol solution according to mass specific gravity. Raw materials according to mass specific gravity are: 90 parts of amino acid, 10 parts of calcium, 10 parts of magnesium, and 10 parts of boron 10 parts of nitrogen, 8 parts of auxin, 100 parts of ethanol solution, the concentration of ethanol solution is 40%, auxin is indole acetic acid, and various raw materials are placed in storage tanks respectively;

[0032] S2: Raw material mixing: Add amino acid, calcium, magnesium, boron, nitrogen, and auxin in step S1 to the ethanol solution in sequence, and mix the amino acid, calcium, magnesium, boron, nitrogen, auxin with the ethanol solution, and the raw materials are mixed using Mixing with a mixer,...

Embodiment 2

[0035] The specific preparation steps of the preparation method of the foliage fertilizer for cotton bud boll anti-shedding and anti-premature aging are as follows:

[0036] S1: Quantitative weighing of raw materials: Weigh amino acid, calcium, magnesium, boron, nitrogen, auxin and ethanol solution according to mass specific gravity. Raw materials according to mass specific gravity are: 100 parts of amino acid, 15 parts of calcium, 15 parts of magnesium, and 15 parts of boron part, 15 parts of nitrogen, 9 parts of auxin, 110 parts of ethanol solution, the concentration of ethanol solution is 45%, auxin is indole acetic acid, and various raw materials are placed in the storage tank respectively;

[0037] S2: Raw material mixing: Add amino acid, calcium, magnesium, boron, nitrogen, and auxin in step S1 to the ethanol solution in sequence, and mix the amino acid, calcium, magnesium, boron, nitrogen, auxin with the ethanol solution, and the raw materials are mixed using The blende...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com