Product conveying and arranging device of intelligent production line

A technology of production line and code sorter, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve problems such as product shaking, skewed product angle placement, and difficulty in accurate identification and grasping in subsequent processes, so as to achieve the accuracy of deviation correction High, increase the effect of adjustment accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

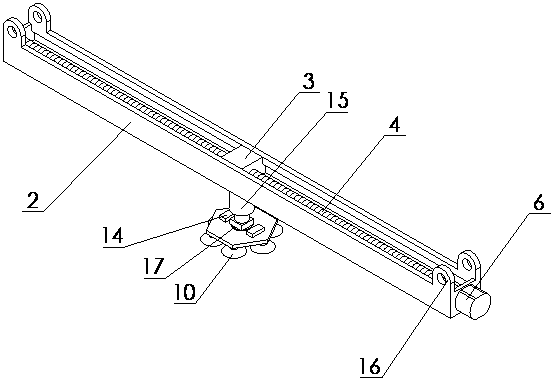

[0020] An intelligent production line product transmission code sorter of the present invention is realized in this way: an intelligent production line product transmission code sorter of the present invention is composed of a sliding rod (1), a sliding frame (2), a sliding block (3), and a No. 1 screw (4), No. 2 lead screw (5), No. 1 motor (6), control box (7), bracket (8), No. 2 motor (9), suction cup (10), camera (11), distance sensor (12), fixed seat (13), vacuum generator (14), electric telescopic rod (15), connecting ear (16), and rotary table (17), and slide bar (1) is placed on one end of support (8) At the top, both ends of the slider (1) are fixedly connected to the bracket (8), and the No. 2 lead screw (5) is placed on the top of the other end of the bracket (8), and is symmetrical to the slider (1). The two ends of the No. 2 screw (5) are fixedly connected by the bearing and the bracket (8) respectively, the No. 2 motor (9) is placed on the bracket (8), and the mot...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is: the vertical support part of the support (8) is replaced by a liftable hydraulic support (19); when in use, it is convenient to adjust the height adaptively to products (18) of different heights ,easy to use.

[0024] The data processor performs information interaction with the ranging sensor (12) and the camera (11), and a computer program is stored in the data processor, and the following steps are implemented when the program is executed:

[0025] Receive the distance signal transmitted by the ranging sensor (12), and perform data processing to obtain the offset distance of the product (18) compared to the center of the conveyor belt, and accept the image signal transmitted by the camera (11), and compare it with the standard image stored in the internal Carry out calculation and comparison to obtain the angle that needs to be adjusted for the product (18) to return to the normal state. When the product (18)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com