A preparation method of integral blisks precisely formed by additive manufacturing and electrolytic machining

A technology of additive manufacturing and integral blisk, applied in the direction of additive processing, etc., can solve the problems of poor material processing performance, long production cycle, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

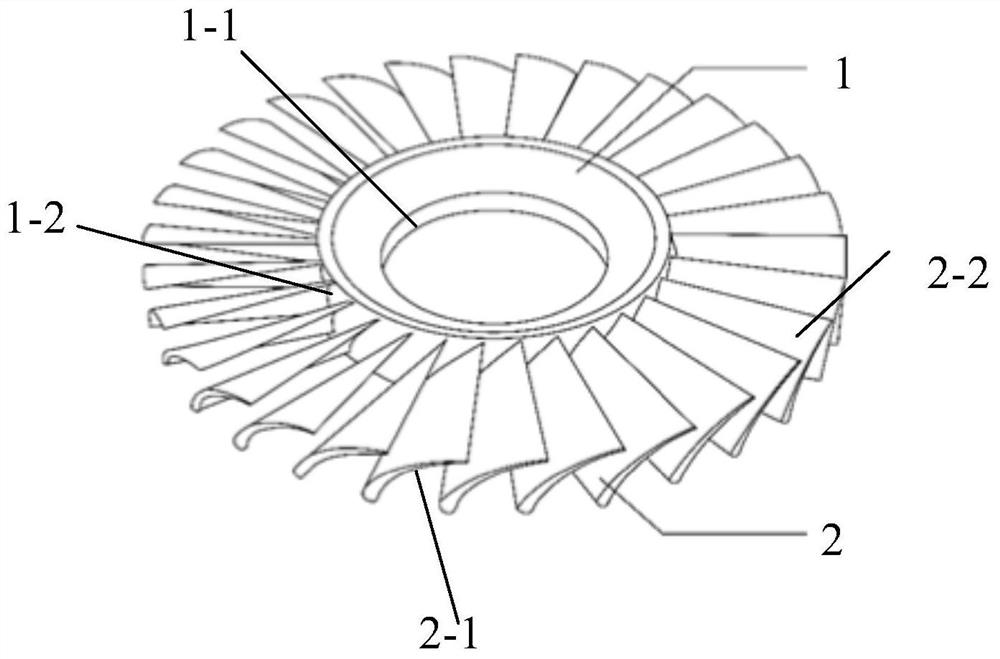

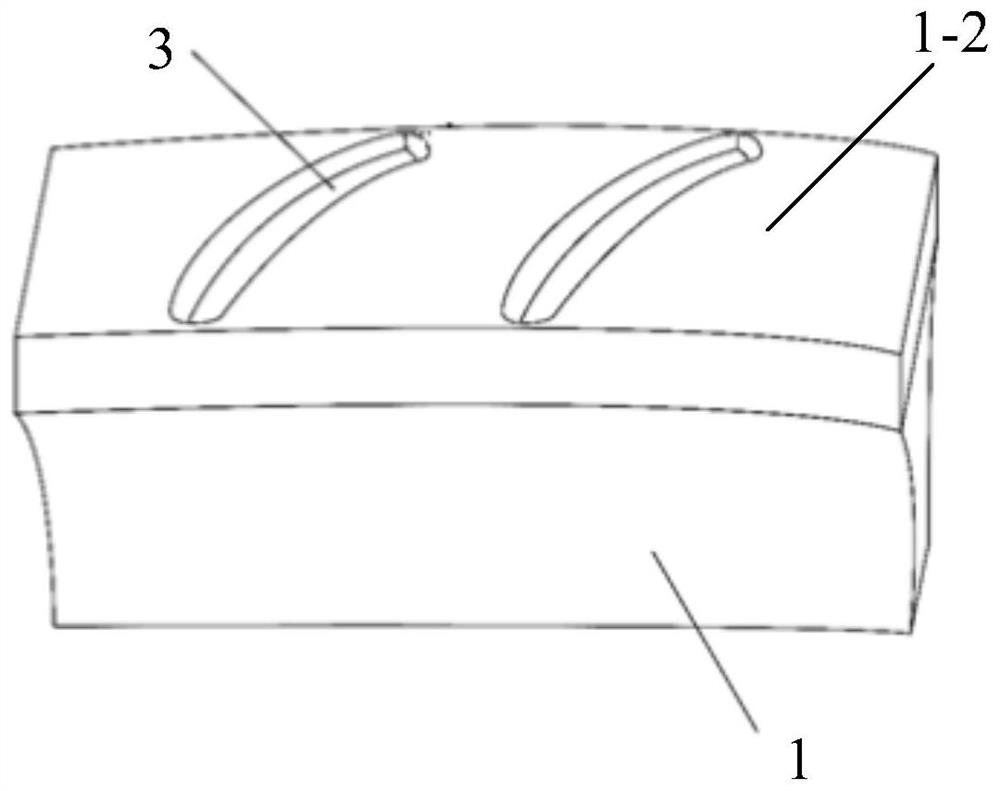

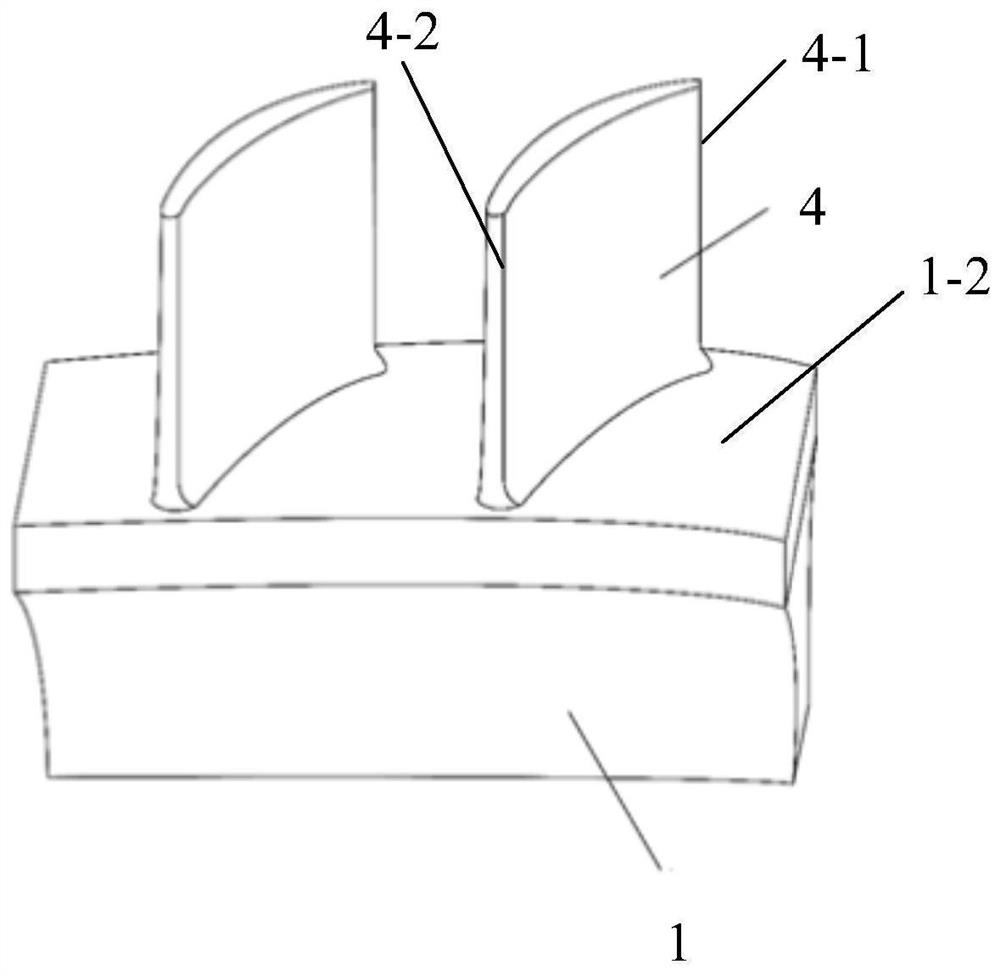

[0043] see figure 1, the present invention discloses a method for preparing a blisk that is accurately formed by additive manufacturing and electrolytic machining; the blisk formed by the target includes a hub 1 and blades 2, the hub 1 is an annular structure, and the hub 1 includes The inner ring surface 1-1 and the outer ring surface 1-2 with the same circle center, the inner ring surface 1-1 is inside the outer ring surface 1-2, the inner ring surface 1-1 is parallel to the outer ring surface 1-2, and the inner ring surface The width of 1-1 is smaller than the width of the outer ring surface 1-2, and the center planes of the inner ring surface 1-1 and the outer ring surface 1-2 in the width direction are the same plane; the two outer sides of the inner ring surface 1-1 The two outer sides of the outer ring surface 1-2 are respectively connected by a slope 1-3, the outer ring surface 1-2 is fixed with grooves 3 along its circumference, and the distance between adjacent groov...

Embodiment 1

[0062] Prepare the TC4 titanium alloy blisk as follows:

[0063] (1) Clamp the prepared forged TC4 titanium alloy disk hub 1 on the processing table of the CNC electrolytic machining machine tool, the cathode tool and the axis of the disk hub 1 form a certain angle on the vertical plane, and after positioning to the processing origin, pass the electrolyte , the cathode tool starts radial feeding to process a groove 3, the depth of the groove 3 is 3 mm, the depth of the groove 3 is 2% of the length of the final blade 2, and the length and width are consistent with the blade body 4 processed later. After one unit operation is completed, it is repeated sequentially along the circumferential direction until all the grooves 3 with the same design number as the blisk blades 2 are finally processed to obtain the preliminarily processed hub 1 .

[0064] The electrolytic machining parameters of groove 3 are: the electrolyte is 15wt.% NaCl solution, the electrolyte temperature is 35°C, ...

Embodiment 2

[0075] Prepare the Ti60 titanium alloy blisk as follows:

[0076] (1) Clamp the prepared forged Ti60 titanium alloy disk hub 1 on the processing table of the CNC electrolytic machining machine tool, the cathode tool and the axis of the disk hub 1 form a certain angle on the vertical plane, after positioning to the processing origin, pass the electrolyte , the cathode tool starts radial feeding to process a groove 3, the depth of the groove 3 is 3mm, the depth of the groove 3 is 3% of the length of the final blade 2, and the length and width are consistent with the blade body 4 processed later. After one unit operation is completed, it is repeated sequentially along the circumferential direction until all the grooves 3 with the same design number as the blisk blades 2 are finally processed to obtain the preliminarily processed hub 1 .

[0077] The electrolytic machining parameters of groove 3 are:

[0078] The electrolyte is 10wt.% NaCl solution, the temperature of the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com