Milk-coated tofu and preparation method thereof

A technology of tofu and slurry, which is applied in the field of food processing, can solve the problems such as the key control points are not clear enough, and achieve the effect of good wrapping effect, rich taste, crispy and flexible skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

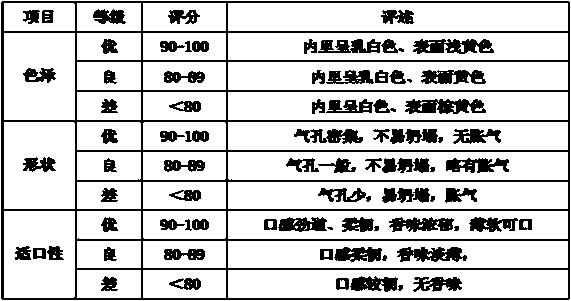

Examples

Embodiment 1

[0024] A kind of preparation method of coated bean curd

[0025] (1) Soaking: Select high-quality northeast non-transgenic soybeans with a soybean protein content of more than 40% for soaking and peeling treatment to obtain peeled soybeans for use. The soaking is 9.5°C water temperature for 11 hours;

[0026] (2) Pulping: Dehulled soybeans are subjected to refining treatment, and the temperature of the machine is lowered while refining. Carry out pulping treatment, pass through a 100-mesh sieve for three times, and get the slurry for subsequent use;

[0027] (3) Burning pulp: Boil at 100°C for 5 minutes, pass the slurry through a 350-mesh sieve after boiling, and then point pulp at 80°C to obtain sour water tofu for later use. The pH value of sour water tofu is 8;

[0028] (4) Packing: sour tofu is packaged, the temperature of the package is not lower than 60°C, and the tofu for every 20 catties of beans must be wrapped within 15 minutes;

[0029] (5) Squeeze: press the air ...

Embodiment 2-11

[0032] A kind of preparation method of coated bean curd

[0033] The preparation process and steps are the same as in Example 1, except that the temperature of the slurry and the appropriate pH value are adjusted during the slurry-spotting stage, as shown in Table 1 for details.

[0034] The point slurry temperature and corresponding pH value of each group of embodiment of table 1

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com