Residual stress prediction method, device, server and storage medium

A technology of residual stress and prediction method, applied in the direction of measuring device, prediction, force/torque/work measuring instrument, etc., can solve the problem of inaccurate contour data and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

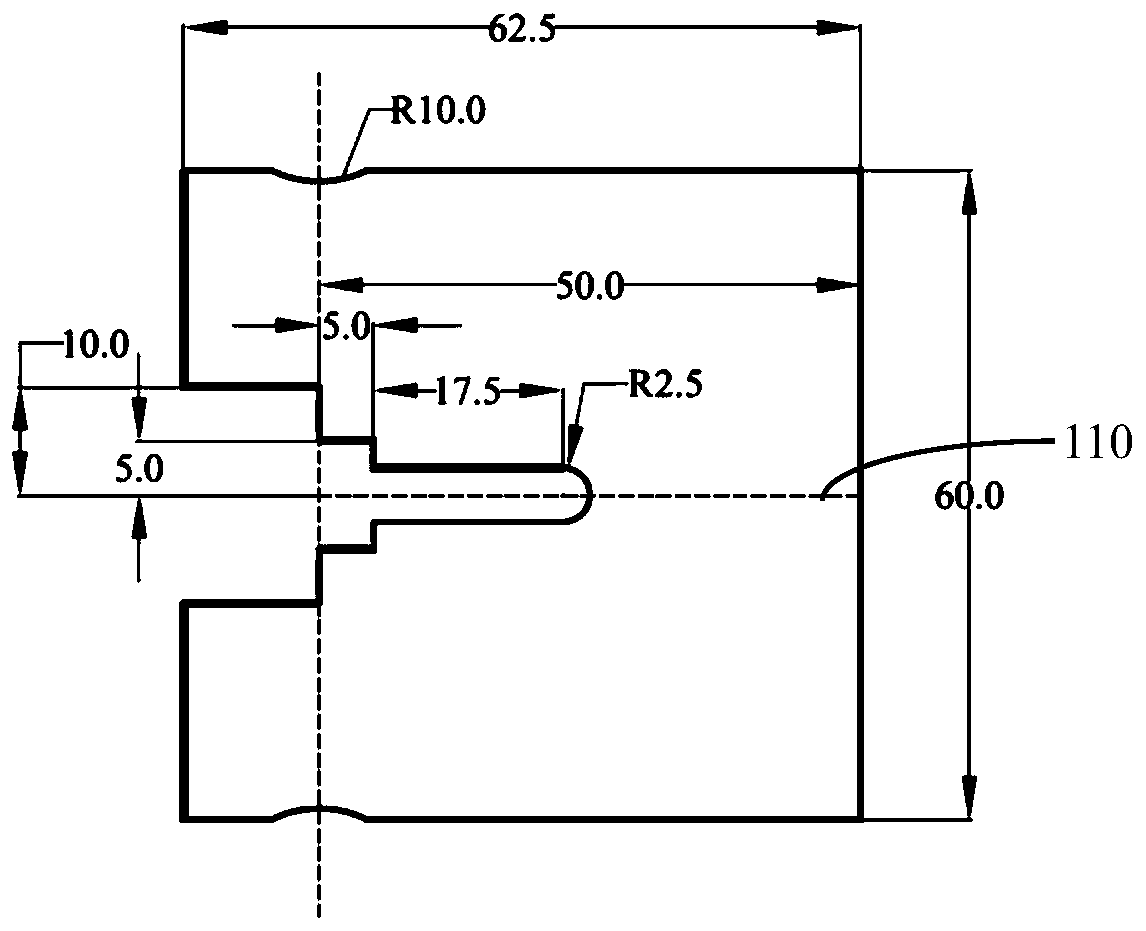

[0089] Embodiment 1 of the present invention provides a method for predicting residual stress. The method is aimed at the measured deformation profile obtained after cutting a test piece containing residual stress using a profile method. The test piece that the present invention adopts is compact tensile test piece, and its shape is as Figure 1a As shown, the cutting surface is at position 110 in the figure, Figure 1b , 1c are the left view and the front view of the compact tensile specimen, respectively, the unit of length is mm, Figure 1d Schematic diagram of the cut compact tensile specimen. It can be understood that the test piece in the embodiment of the present invention may also be another type of test piece, which is not limited in the present invention. After cutting, measure based on the cutting surface of the specimen, such as Figure 1e As shown, the cutting starting position of the measuring cutting surface is the notch end 120 of the test piece, the measuri...

Embodiment 2

[0146] The residual stress prediction device 800 provided in Embodiment 2 of the present invention can execute the residual stress prediction method provided in any embodiment of the present invention, and has corresponding functional modules and beneficial effects for executing the method. The device can be composed of software and / or hardware (integrated circuit) and can generally be integrated into a server or terminal device. Figure 8 It is a schematic structural diagram of a residual stress prediction device 800 in Embodiment 2 of the present invention. refer to Figure 8 , the residual stress prediction device 800 in the embodiment of the present invention may specifically include:

[0147] The construction unit 810 is used to construct a stress function, wherein the independent variable of the stress function is the distance between the measurement point and the notch end of the test piece, and the dependent variable is the residual stress of the measurement point;

...

Embodiment 3

[0203] Figure 9 A schematic structural diagram of a device / terminal / server provided in Embodiment 3 of the present invention, such as Figure 9 As shown, the device / terminal / server includes a processor 910, a memory 920, an input device 930, and an output device 940; the number of processors 910 in the device / terminal / server may be one or more, Figure 9 Take a processor 910 as an example; the processor 910, memory 920, input device 930 and output device 940 in the device / terminal / server can be connected by bus or other methods, Figure 9 Take connection via bus as an example.

[0204] The memory 920, as a computer-readable storage medium, can be used to store software programs, computer-executable programs and modules, such as program instructions / modules corresponding to the subject update method in the embodiment of the present invention (for example, the residual stress prediction device 800 construction unit 810, extension unit 820, expansion unit 830, calculation unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com