Real-time monitoring device for service life of automobile filter and monitoring method thereof

A real-time monitoring and filter technology, applied to fuel air filters, charging systems, machines/engines, etc., can solve the problems of lack of environmental data input, inability to formulate standards and regulations, etc., and achieve the effect of convenient and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

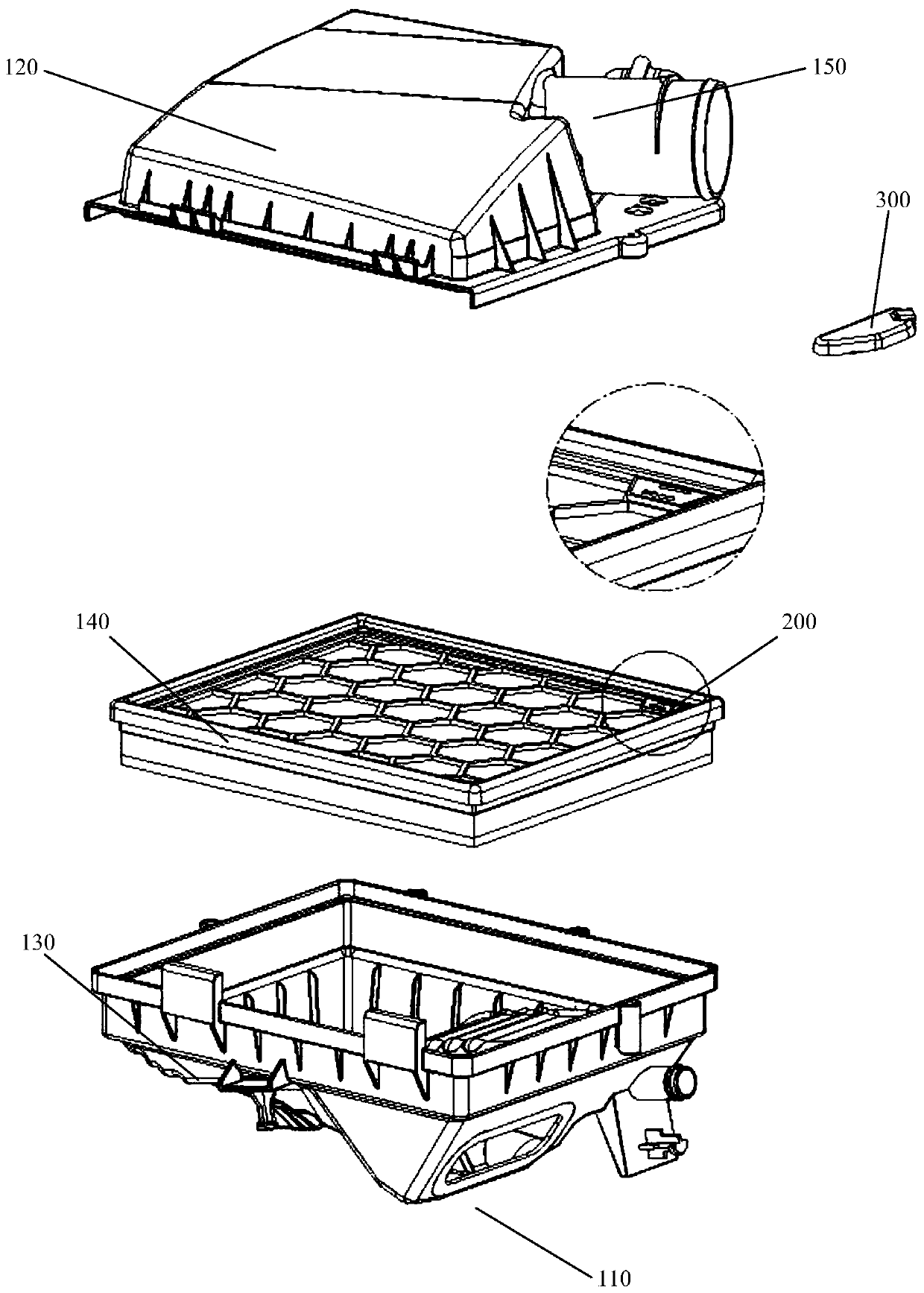

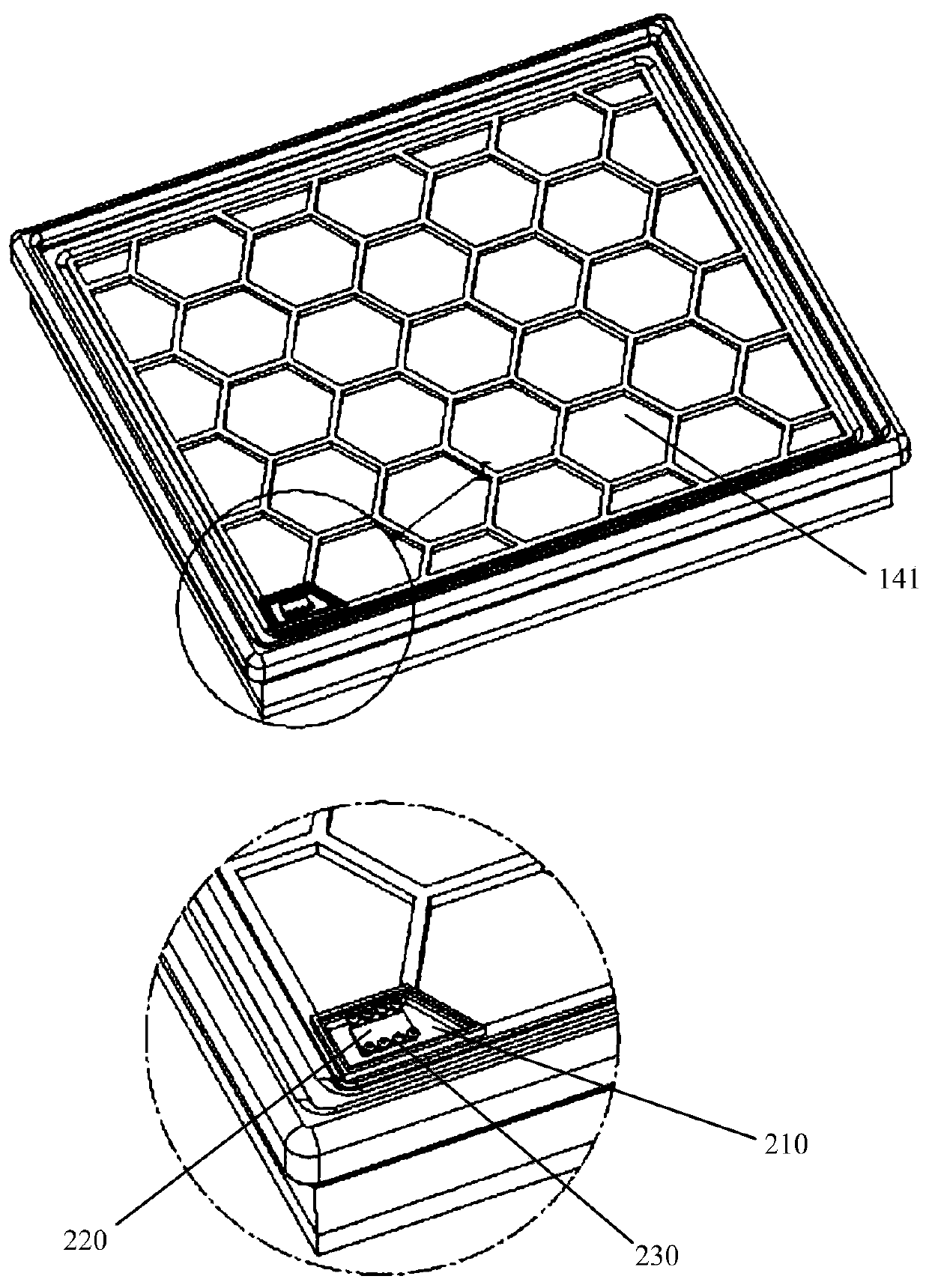

[0048] Such as figure 1 , figure 2 , image 3 As shown, a real-time monitoring device for the service life of an automobile filter includes: an air filter 100, a filter unit 200, a filter unit 300 and a data terminal 400, and the filter unit 200 is internally connected to the air filter 100, The filter unit 300 is fixed on the top shell of the air filter 100 , and the data terminal 400 is connected to the filter unit 300 .

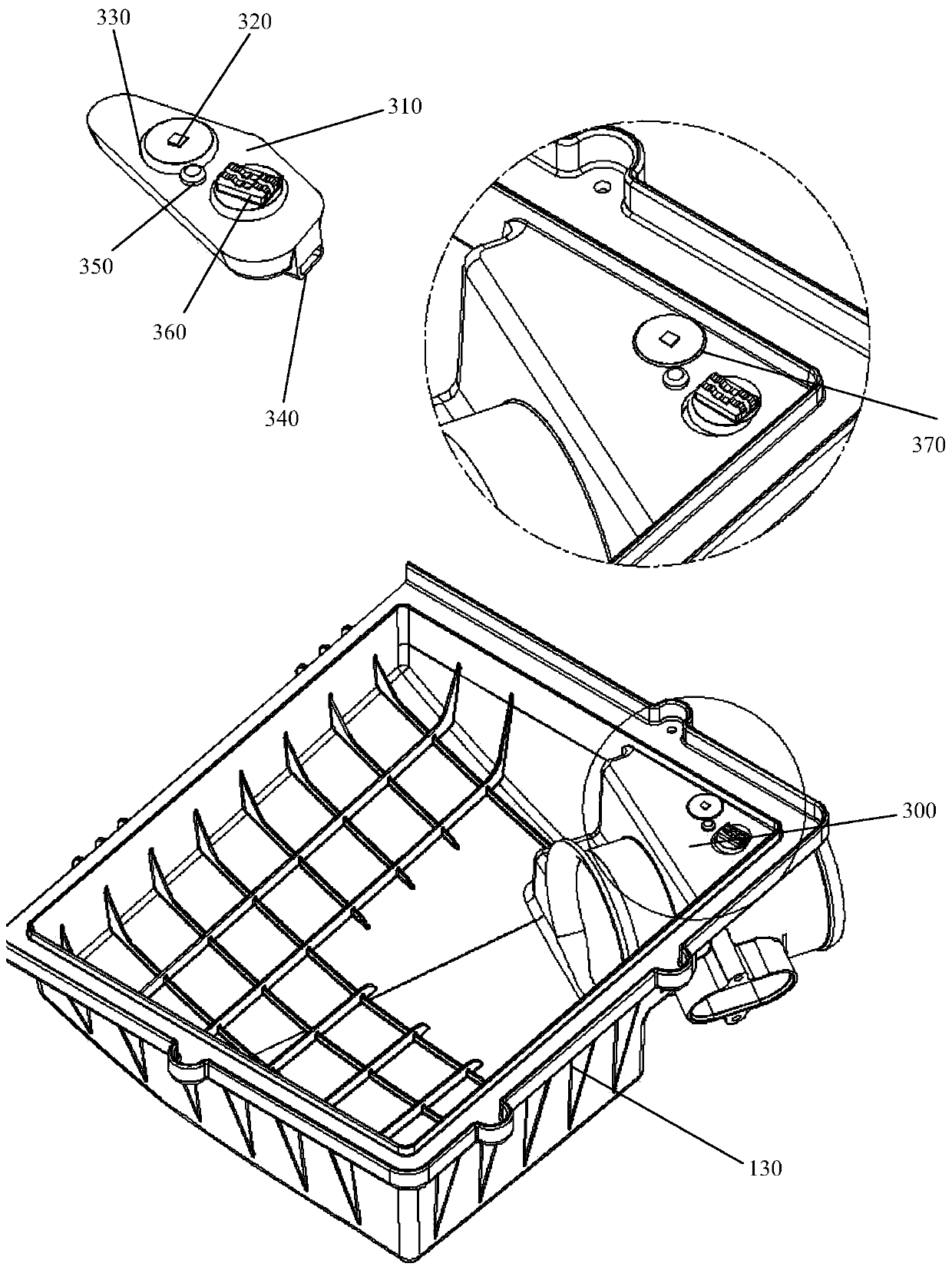

[0049]Wherein, the filter unit 300 includes: a vehicle unit 310, a pressure sensing system 320, a sealing installation structure 330, a data transmission interface 340, a fastening screw 350 and a filter unit contact pin 360, and the vehicle unit 310 is connected to the filter unit through the fastening screw 350. The upper housing 120 of the cleaner is connected, the pressure sensing system 320 and the contact pin 360 of the filter element unit are arranged in the installation hole 370 of the vehicle unit 310, and the installation hole 370 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com