An engine misfire detection method, device and system

A detection method and detection device technology, applied in the direction of combustion engine, engine control, machine/engine, etc., can solve the problems of cylinder misfire, undetectable misfire, undetectable misfire, etc., and achieve the effect of avoiding misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

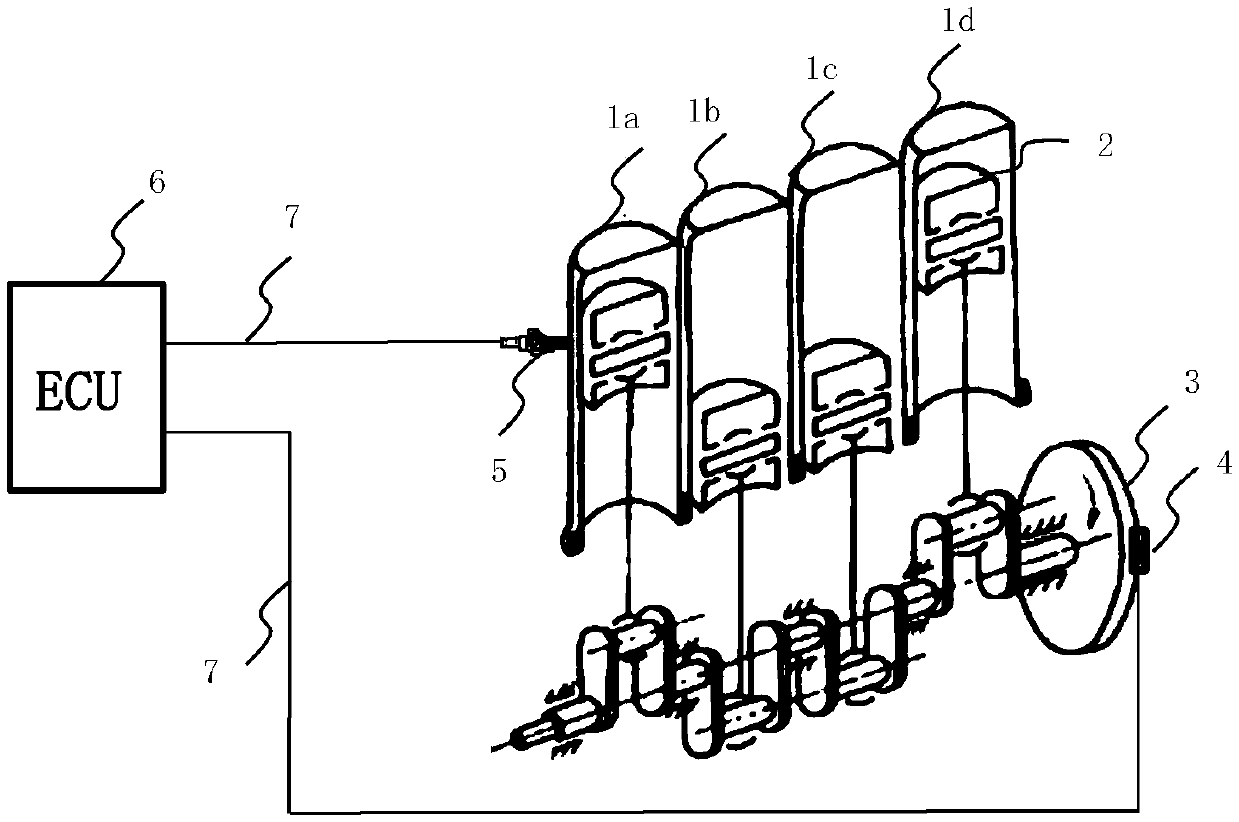

[0038] figure 1 is a schematic structural diagram of a misfire detection system 10 for an engine according to an embodiment of the present invention. Such as figure 1 As shown, the misfire detection system 10 includes a plurality of cylinders 1a-1d, a knock sensor 5, a crankshaft sensor 4, a piston 2, a crankshaft 3, and a misfire detection device 6 of the engine. In the following, when each cylinder is described separately, the corresponding letter will be added after the number 1, such as 1a, 1b, 1c or 1d, while in other cases, only the number 1 will be used.

[0039] Combustion of the gas entering the cylinder 1 drives the piston 2 to make a reciprocating motion. The crankshaft 3 connected to the cylinder 1 and the piston 2 is equipped with a crankshaft sensor 4, based on the signal detected by the crankshaft sensor 4, the position and speed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com