A temporary support device used in tunnel excavation and its implementation method

A technology for temporary support and tunnel excavation, applied in temporary shields, tunnels, tunnel linings, etc., can solve problems affecting stability and safety, difficulty in installation and disassembly, and increased manpower expenditure to ensure stability and safety, save construction time and cost, and improve the service life of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

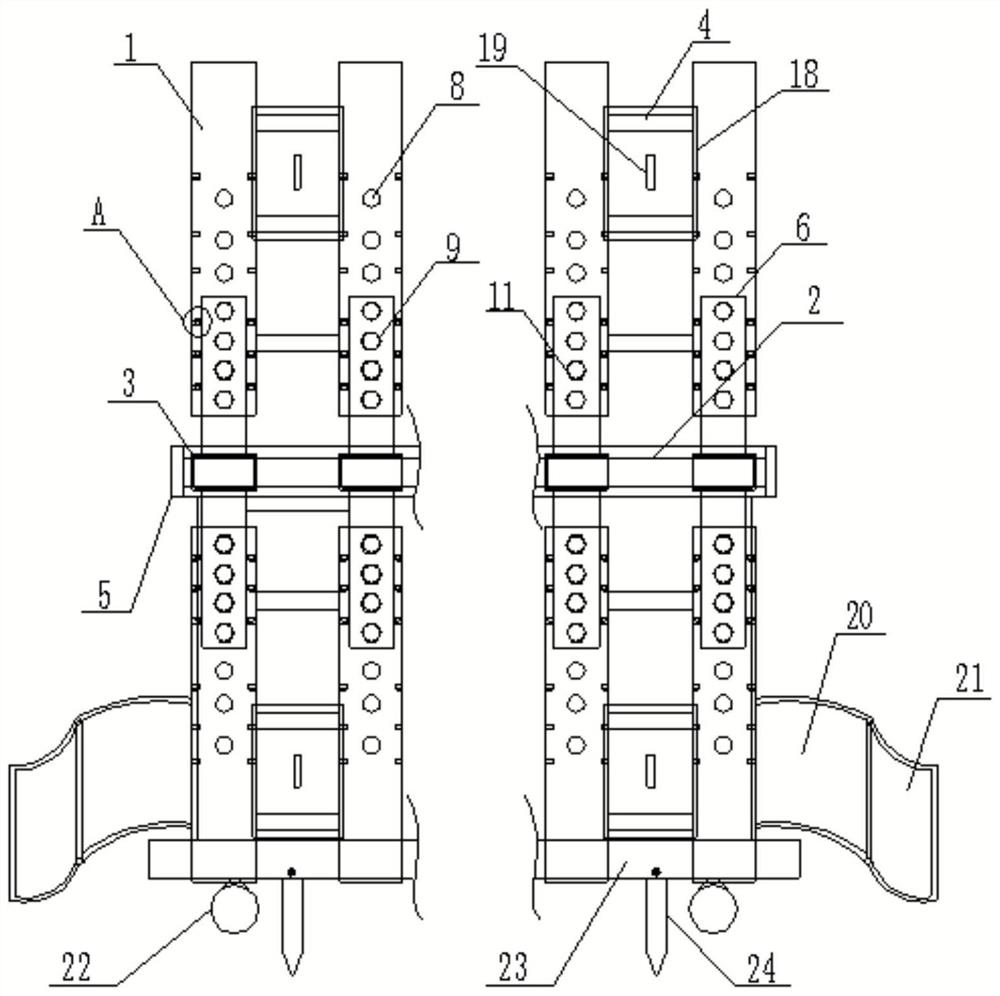

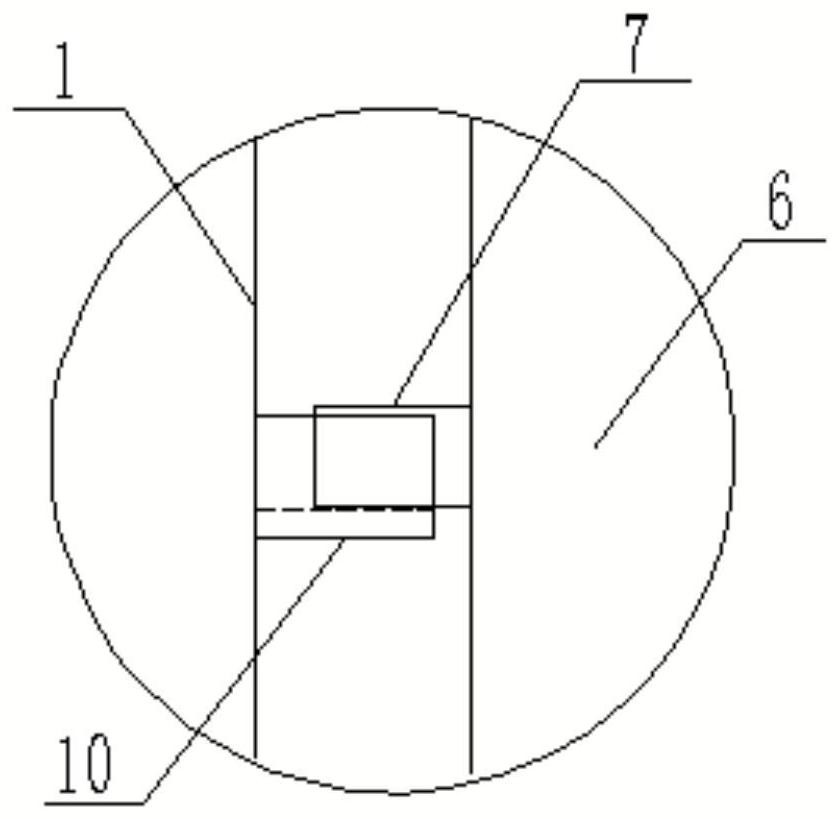

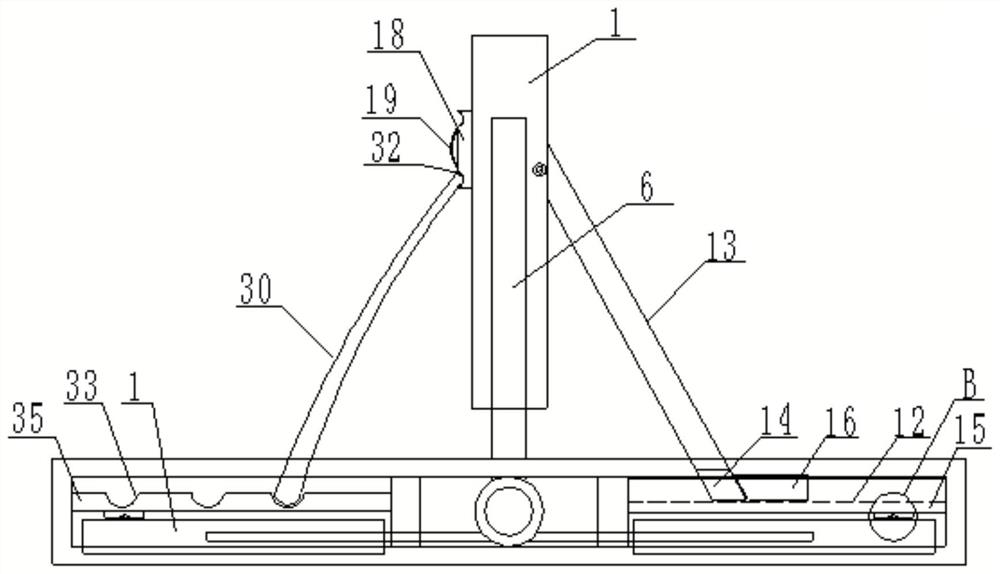

[0034] Such as Figure 1-7As shown, the present invention provides a kind of temporary supporting device, comprises several groups of protective mechanisms, each group of protective mechanisms is detachably connected, and ear plates (not shown in the figure) are installed on two steel frames 1 next to each group of protective mechanisms. display), when it is necessary to use multiple sets of protective mechanisms for splicing, the lug plates can be directly connected with bolts, which not only facilitates installation and disassembly, but also reduces the cost of use; the protective mechanism includes a fixed frame 5, on which the The fixed shaft 2 is disassembled and connected, and the fixed shaft 2 is movably connected with a rotating sleeve 3, and several adjusting plates 6 are movably connected on the rotating sleeve 3, and a slide rail (not shown in the figure) is provided on the rotating sleeve 3, and the adjusting plate 6 is slidingly connected in the rotating sleeve 3 ...

Embodiment 2

[0049] Such as Figure 1-6 Shown in and 8, the present invention also provides a kind of implementation method that adopts above temporary support device, when adopting CD method construction, its implementation comprises the following steps:

[0050] (1) Assembly outside the hole: erect and assemble the prepared steel frame 1, fixed frame 5, fixed shaft 2 and other components outside the hole, first install the fixed shaft 2 on the fixed frame 5, and then install the rotating sleeve 3 Sleeve on the fixed shaft 2, then install the adjustment plate 6 in sequence, and connect the steel frame 1 to the adjustment plate 6 through the fastener 11, and connect several steel frames 1 through the connecting rib 4 to form a preliminary protection mechanism. Since the CD method is used for construction, repeat the above steps to install two sets of preliminary protection mechanisms on the fixed shaft 2;

[0051](2) Adjustment outside the cave: Since the CD method is used for constructio...

Embodiment 3

[0055] Such as Figure 1-6 Shown in and 9, the present invention also provides a kind of implementation method that adopts above temporary support device, when adopting double sidewall pilot pit method construction, its implementation comprises the following steps:

[0056] (1) Assembly outside the hole: erect and assemble the prepared steel frame 1, fixed frame 5, fixed shaft 2 and other components outside the hole, first install the fixed shaft 2 on the fixed frame 5, and then install the rotating sleeve 3 Sleeve on the fixed shaft 2, then install the adjustment plate 6 in sequence, and connect the steel frame 1 to the adjustment plate 6 through the fastener 11, and connect several steel frames 1 through the connecting rib 4 to form a preliminary protection mechanism. Since the double-side wall pilot pit method is used for construction, repeat the above steps to install four sets of preliminary protection mechanisms on the fixed shaft 2;

[0057] (2) Adjustment outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com