Natural gas deacidification module

A natural gas and deacidification technology, which is applied in gas fuel, gas treatment, membrane technology, etc., can solve the problems of high manufacturing cost, redundant design, and large number of equipment, and achieve system complexity, cost reduction, and floor space reduction Effect of small size and reduction in the number of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

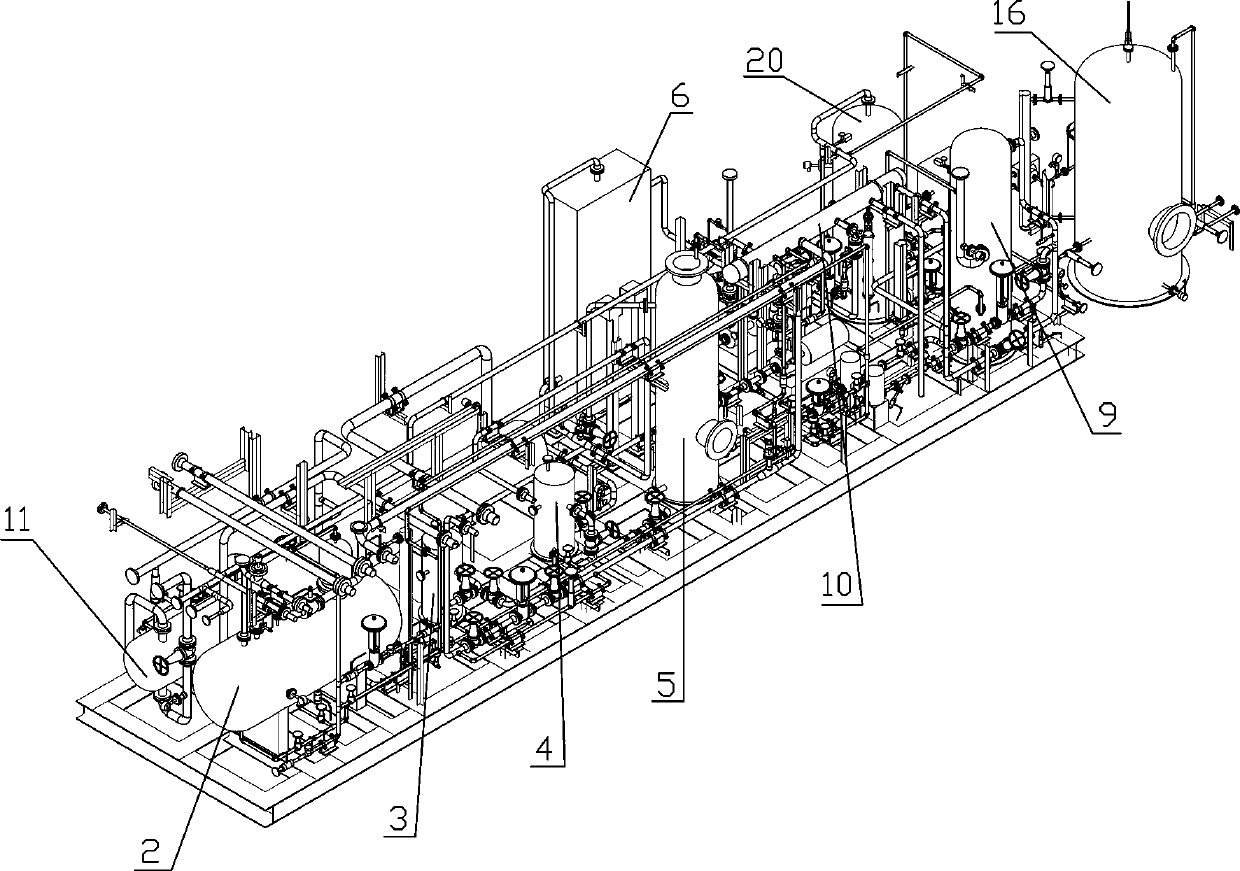

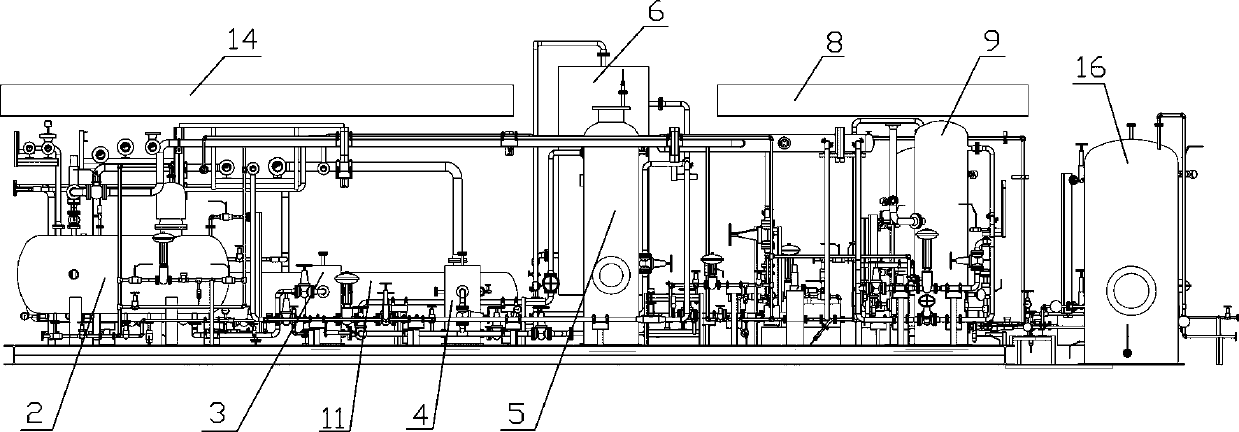

[0020] Such as figure 1 As shown, a natural gas deacidification module includes: an amine absorption tower 1, an amine liquid flash tank 2, a fuel gas tank 20, a first amine mechanical filter 3, an amine activated carbon filter 4, and a second amine mechanical filter 5 , lean amine liquid heat exchanger 6, amine regeneration tower 7, amine buffer tank 12, amine reflux collection tank 9, regeneration tower top condenser 8, regeneration tower reflux pump 10, lean amine liquid booster pump 13, lean amine cooler 14. Reboiler 11 at the bottom of the tower; the amine absorption tower 1 is provided with raw material gas inlet, raw material gas outlet, rich amine liquid outlet, and lean amine liquid inlet. The raw material gas is deacidified by reacting with the amine solution in the amine absorption tower 1 , the amine solution after the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com