Telescopic cantilever and telescopic cantilever type plate turnover machine comprising same

A turning machine and cantilever type technology, applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problem of inability to turn over large-sized glass, and achieve the effect of avoiding vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

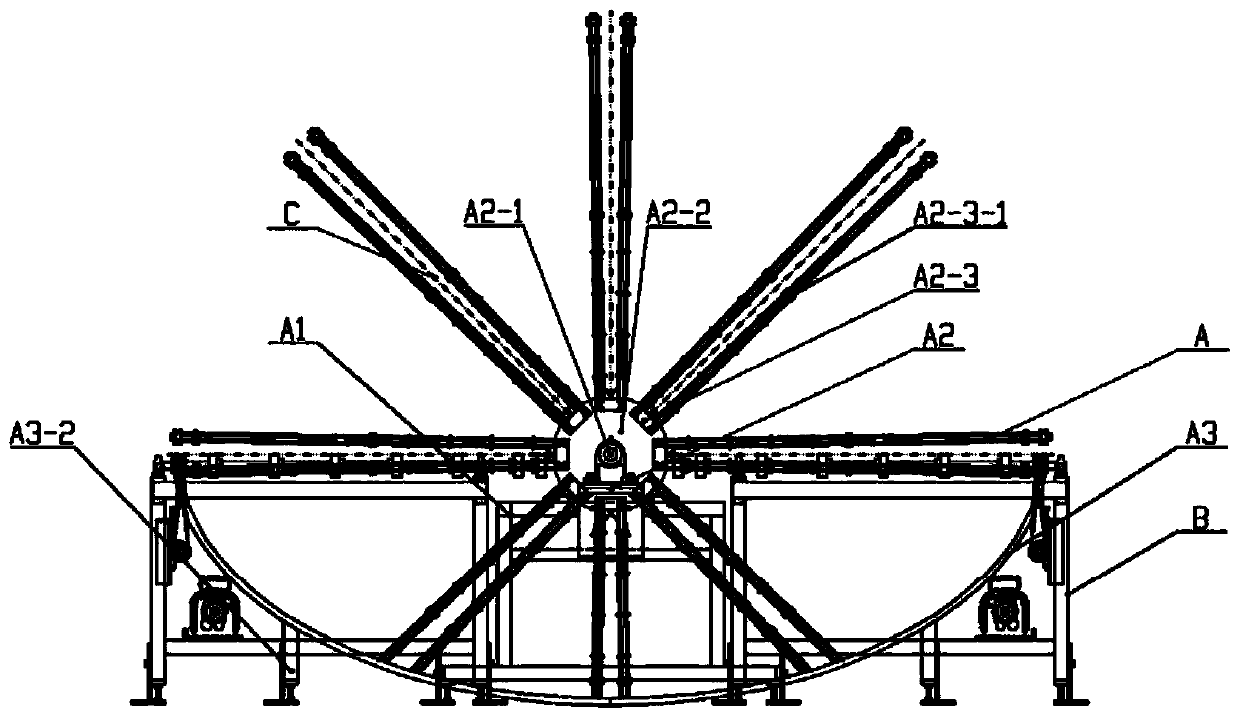

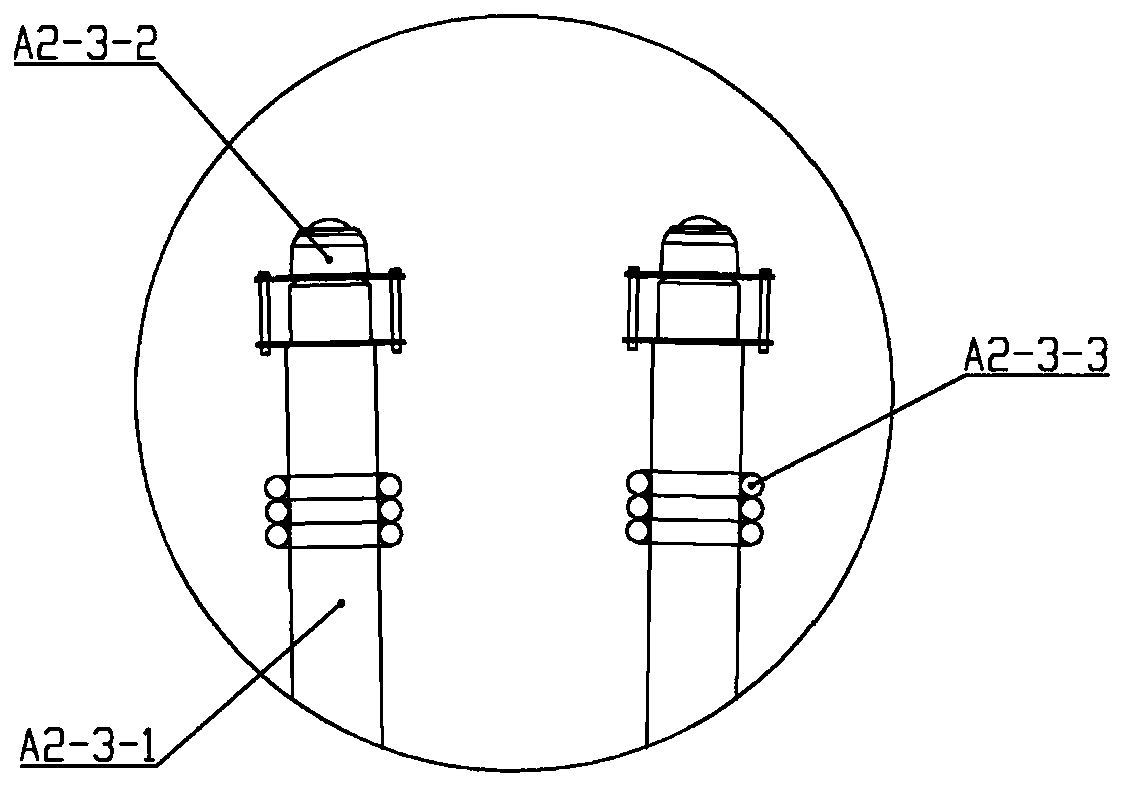

[0032] Such as figure 1 As shown, this embodiment provides a sun-wheel type glass turning machine, which includes a clamping cantilever assembly A2-3, and the clamping cantilever assembly A2-3 includes a fixed plate and two clamping cantilevers A2-3-1, The two clamping arms A2-3-1 are respectively arranged on one side of the fixing plate.

[0033] In this specific example, if Figure 1-5 As shown, there is an included angle of 1 degree between the two clamping cantilevers A2-3-1. A plurality of O-shaped rubber rings A2-3-3 are sheathed on the clamping cantilever A2-3-1. A V-shaped block is also arranged on the fixed plate between the two clamping arms A2-3-1, and a V-shaped groove is arranged on the side of the V-shaped block away from the fixed plate. A guide wheel is arranged in the V-shaped groove. The clamping arm A2-3-1 is a support rod. A bull's-eye universal ball A2-3-2 is provided at the end of the support rod away from the fixed plate.

Embodiment 2

[0035] The present invention also provides a retractable cantilever type turning machine comprising the retractable cantilever of Embodiment 1, including a frame A1, a turning device A2, an arc guide rail A3 and a driving mechanism; the turning device A2 is arranged on the On the frame A1, the arc-shaped guide rail A3 is arranged on the frame A1 and directly below the turning device A2, and the driving mechanism is used to drive the turning device A2.

[0036] The overturning device A2 includes a mandrel on which four rotary disks A2-2 are arranged, and each of the rotary disks A2-2 is provided with eight clamping cantilever assemblies A2-3 in the circumferential direction One end of the clamping cantilever assembly A2-3 away from the fixing plate is slidably disposed in the arc-shaped guide rail A3.

[0037] Establish a space Cartesian coordinate system with the axis of the mandrel A2-1 as the Z axis, the original length of the clamping cantilever A2-3-1 is L, and the conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com