Distributed driving vehicle chassis

A distributed, vehicle-based technology, applied in the directions of drive interaction, control drive, electric vehicles, etc., can solve problems such as complex sensors and practical applications that do not have guiding significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

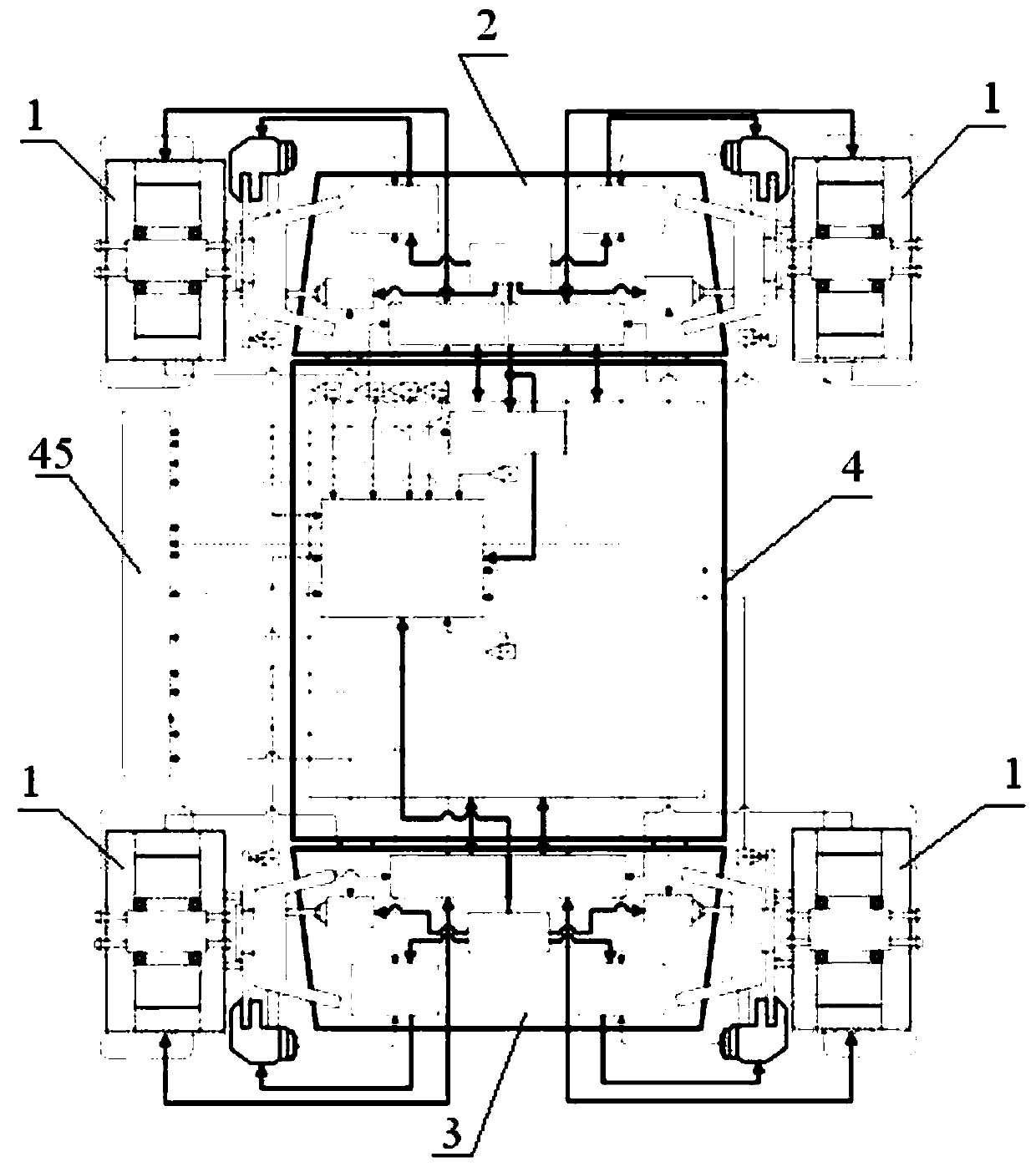

[0043] see Figure 1 to Figure 5 Shown:

[0044] The distributed drive vehicle chassis provided by the present invention includes four in-wheel motor drive brake assemblies 1, a front sub-frame assembly 2, a rear sub-frame assembly 3 and a frame assembly 4, wherein the front sub-frame assembly The component 2 and the rear sub-frame assembly 3 are respectively assembled at the front and rear of the frame assembly 4, and the two hub motor drive brake assemblies 1 are respectively assembled at both sides of the front sub-frame assembly 2, and the remaining two hub motors The drive brake assembly 1 is respectively assembled on both sides of the rear sub-frame assembly 3 .

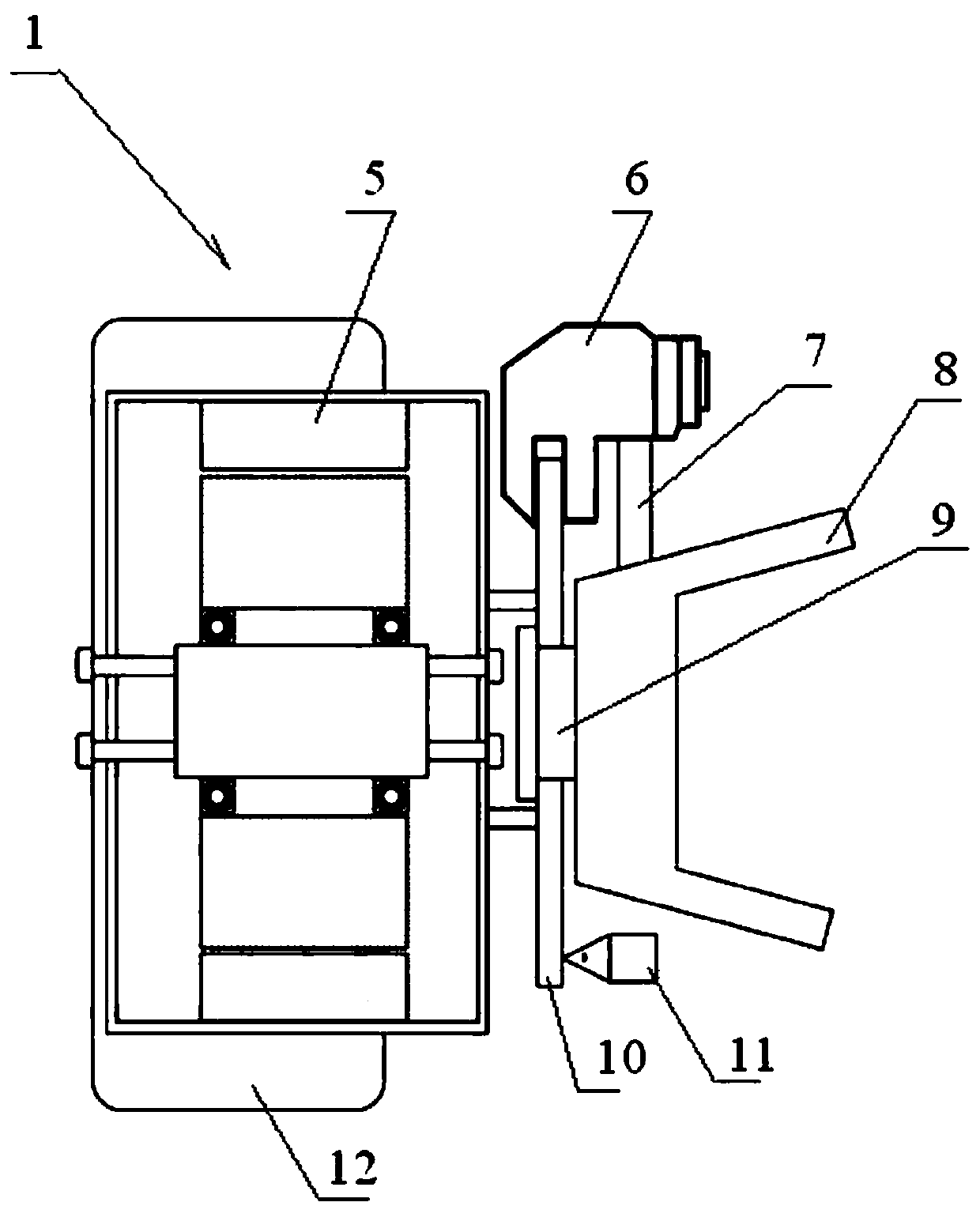

[0045] The four hub motor drive brake assemblies 1 have the same structure, and each hub motor drive brake assembly 1 includes a hub motor 5, an electric caliper 6, an electric caliper fixing bracket 7, a double wishbone suspension 8, and a wheel hub 9 , the brake disc 10, the wheel speed sensor 11 and the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com