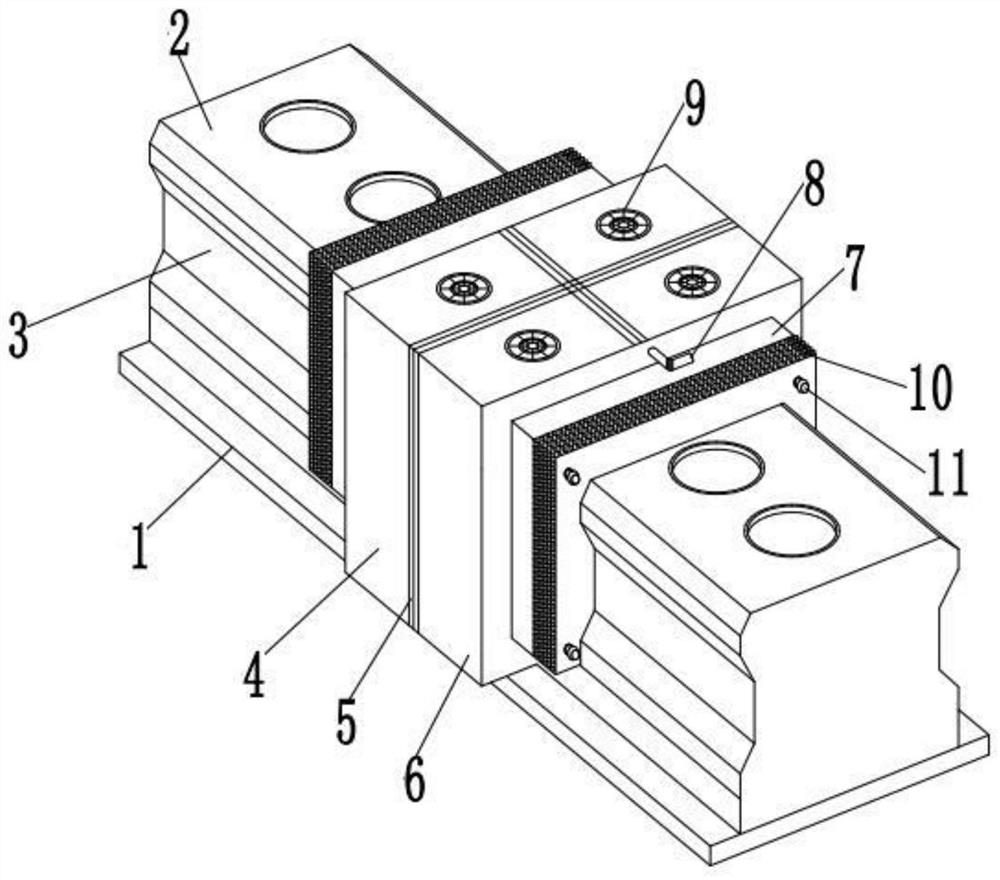

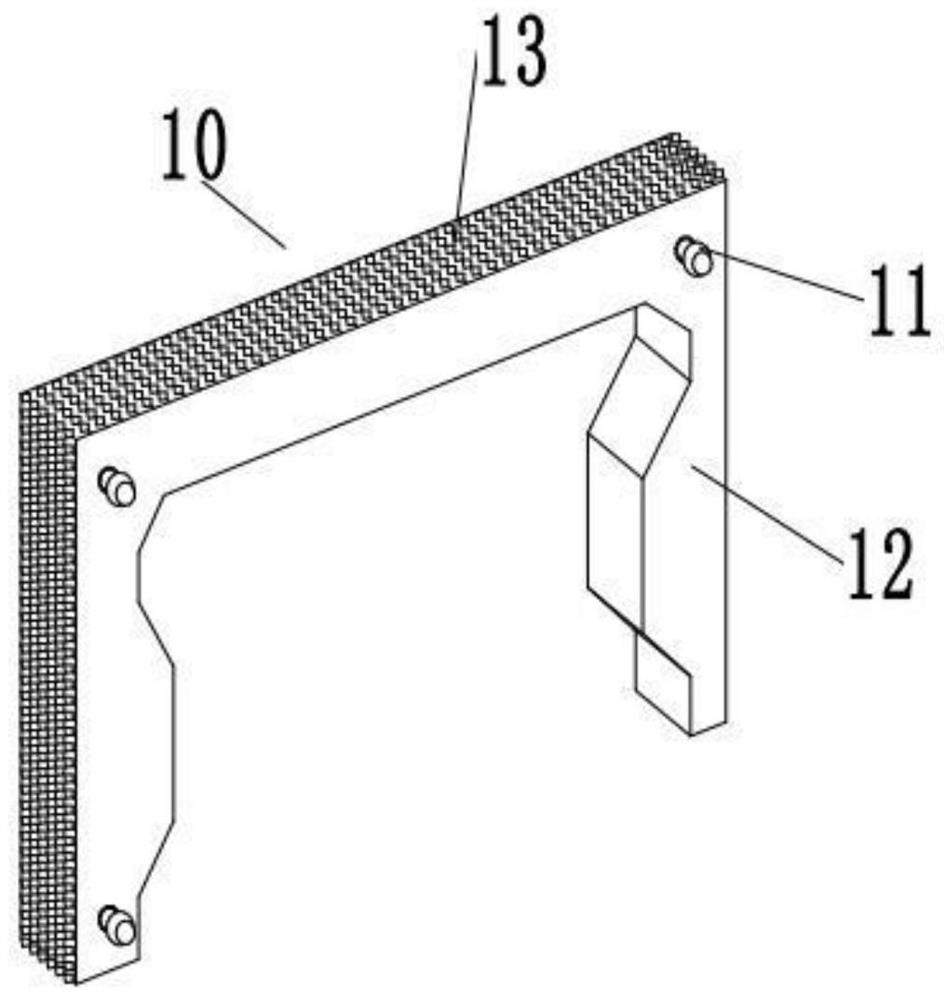

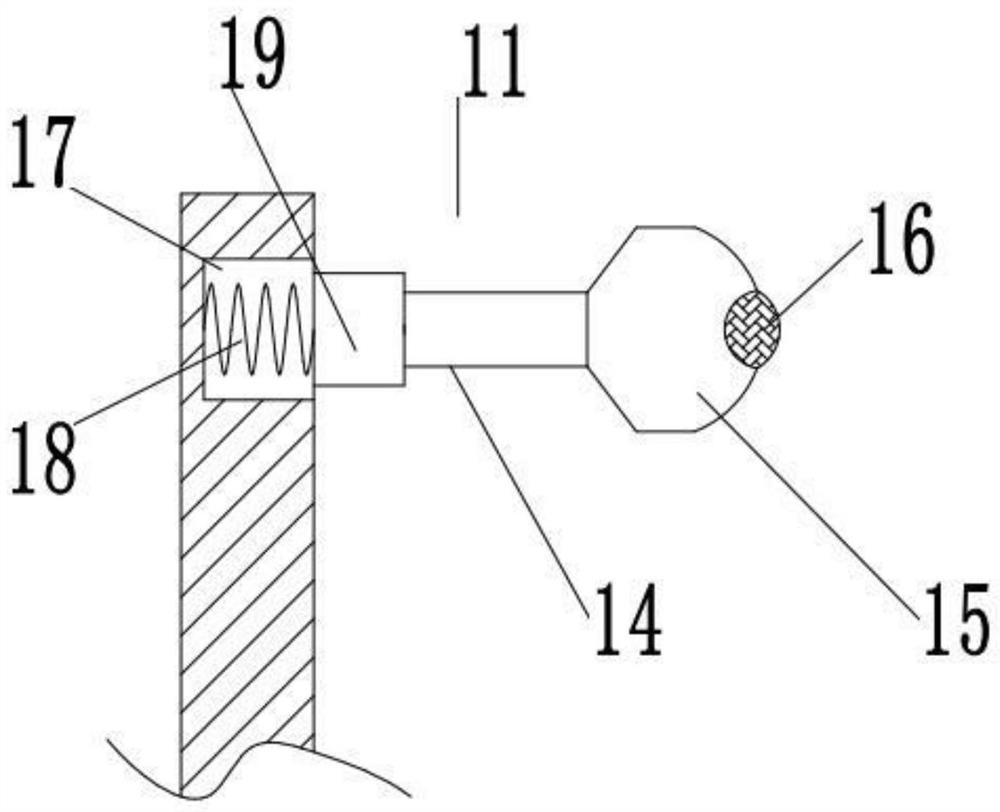

A linear slide rail with cushioning and anti-collision function

A linear slide rail and anti-collision technology, applied in the field of linear guide rails, can solve the problems affecting the normal use of linear slide rails, the cracking of sliders, collisions, etc., and achieve the effect of lifting effect, prolonging service life and reasonable movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0023]It should be noted that the component is referred to as "fixed to" another component, which can be directly in another component or may also exist. When a component is considered to be "connected" another component, it can be directly connected to another component or may exist at the same time. When a component is considered "set to" another component, it can be directly set on another component or may exist at the same time. The terms "vertical", "horizontal", "left", "right", and similar expressions are merely for illust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com