A positioning device for assembling heat dissipation fins of an evaporator

A technology of positioning device and cooling fins, applied in auxiliary devices, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of low efficiency and labor consumption, and achieve the effect of ensuring positioning effect, good positioning effect and saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

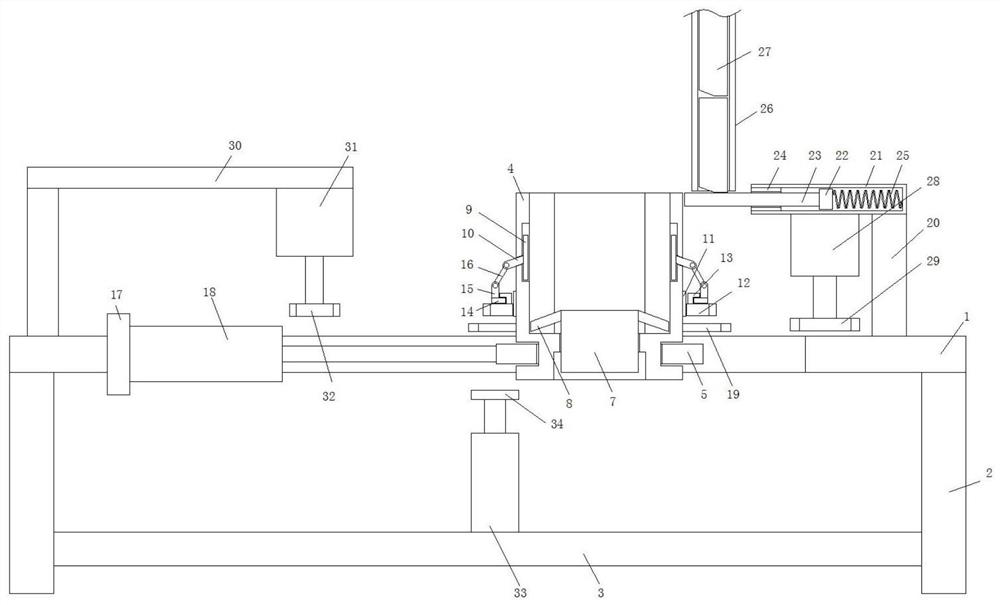

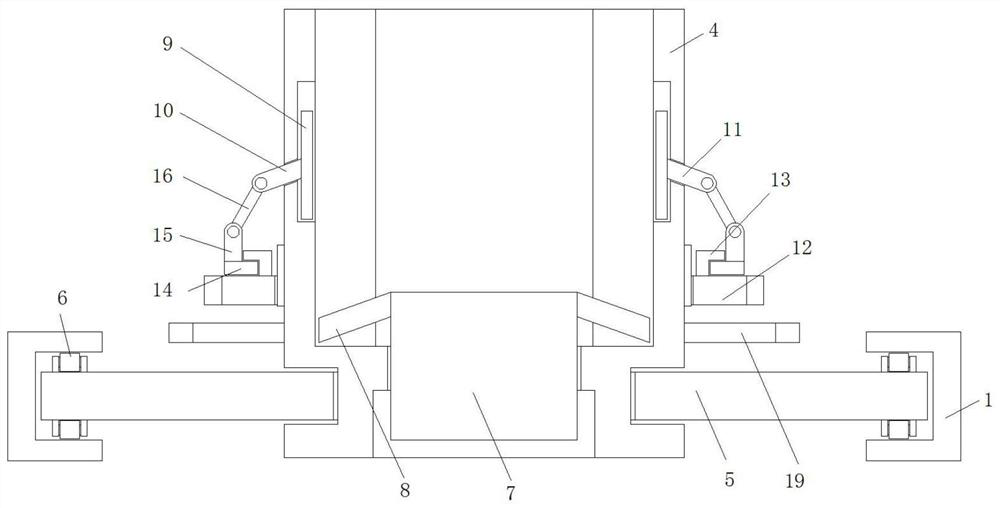

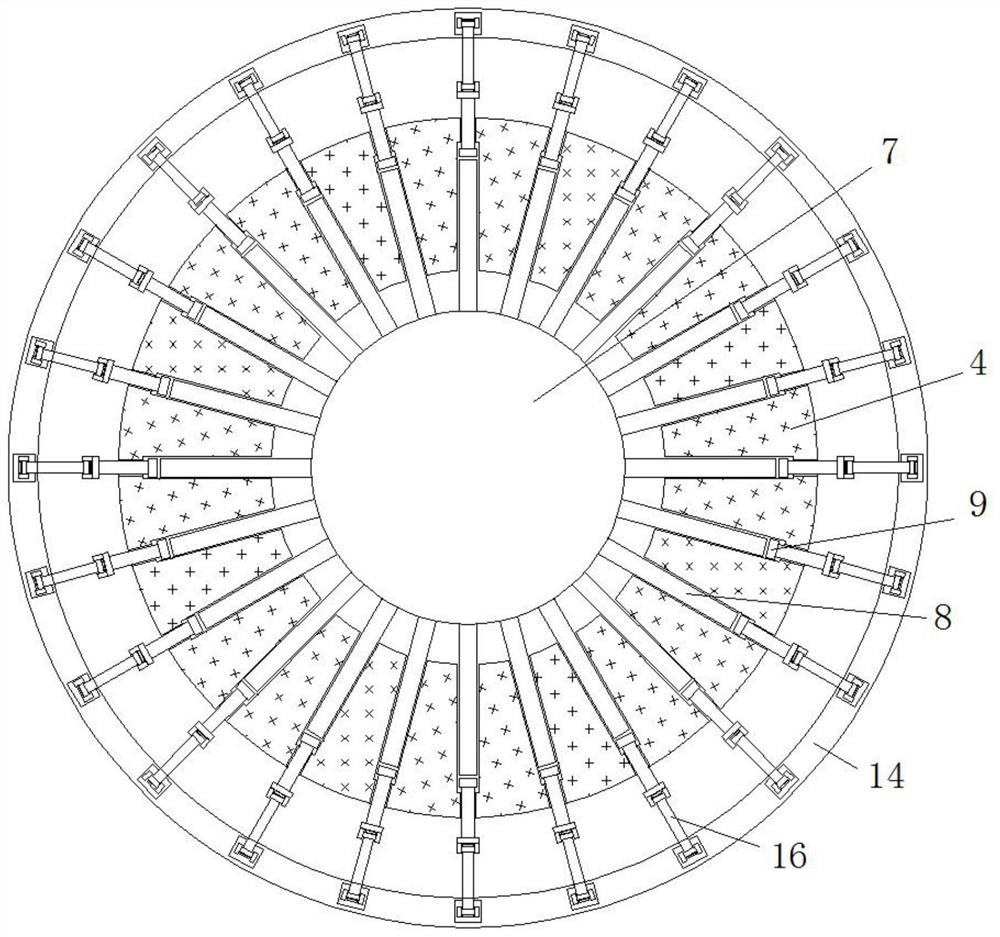

[0022] refer to Figure 1-3 , a positioning device for assembling heat dissipation fins of an evaporator, including a workbench 1, feet 2 are fixedly connected to the four corners of the bottom of the workbench 1, a partition 3 is arranged between the feet 2, and the partition 3 is horizontally arranged on the workbench 1 Vertically below the workbench 1 is provided with a vertical through hole, and the inner walls on both sides of the vertical through hole are provided with track chutes, the vertical through hole is provided with a positioning cylinder 4, and the outer wall of the positioning cylinder 4 is provided with a The annular groove and the rotating sleeve are provided with a rail slide 5, the two sides of the rail slide 5 respectively extend into the track chute, and the top side and the bottom four corners of the rail slide 5 are provided with pulleys 6, and the top of the positioning cylinder 4 is an opening structure, and the inner wall of the positioning cylinder...

Embodiment 2

[0026] Such as Figure 1-3As shown, this embodiment is basically the same as Embodiment 1. Preferably, the inner wall of one side of the vertical through hole is fixedly connected with a mounting plate 17, and one side of the mounting plate 17 is fixed with a cylinder one 18 by bolts, and the cylinder one The output bar of 18 is fixedly connected with one side of track slide plate 5.

[0027] In this embodiment, the setting of cylinder one 18 is to drive the horizontal movement of the track slide 5 , so as to complete the conversion of the station of the positioning cylinder 4 .

Embodiment 3

[0029] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the top side of the partition plate 3 is fixed with a cylinder 2 33 by bolts, and the output rod of the cylinder 2 33 is fixedly connected with a bottom push plate 34, and the bottom push plate 34 Matches the underside of the sliding base 7.

[0030] In this embodiment, the second cylinder 33 pushes the fin plate 27 on the top of the sliding base 7 and the top of the cylindrical utensil to protrude from the top of the positioning cylinder 4 through the bottom push plate 34 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com