Fabric double-sided coating machine

A coating machine, double-sided technology, applied in the direction of coating, liquid coating device on the surface, thin material processing, etc., can solve the problems of cost increase and low efficiency, and achieve the effect of ensuring the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

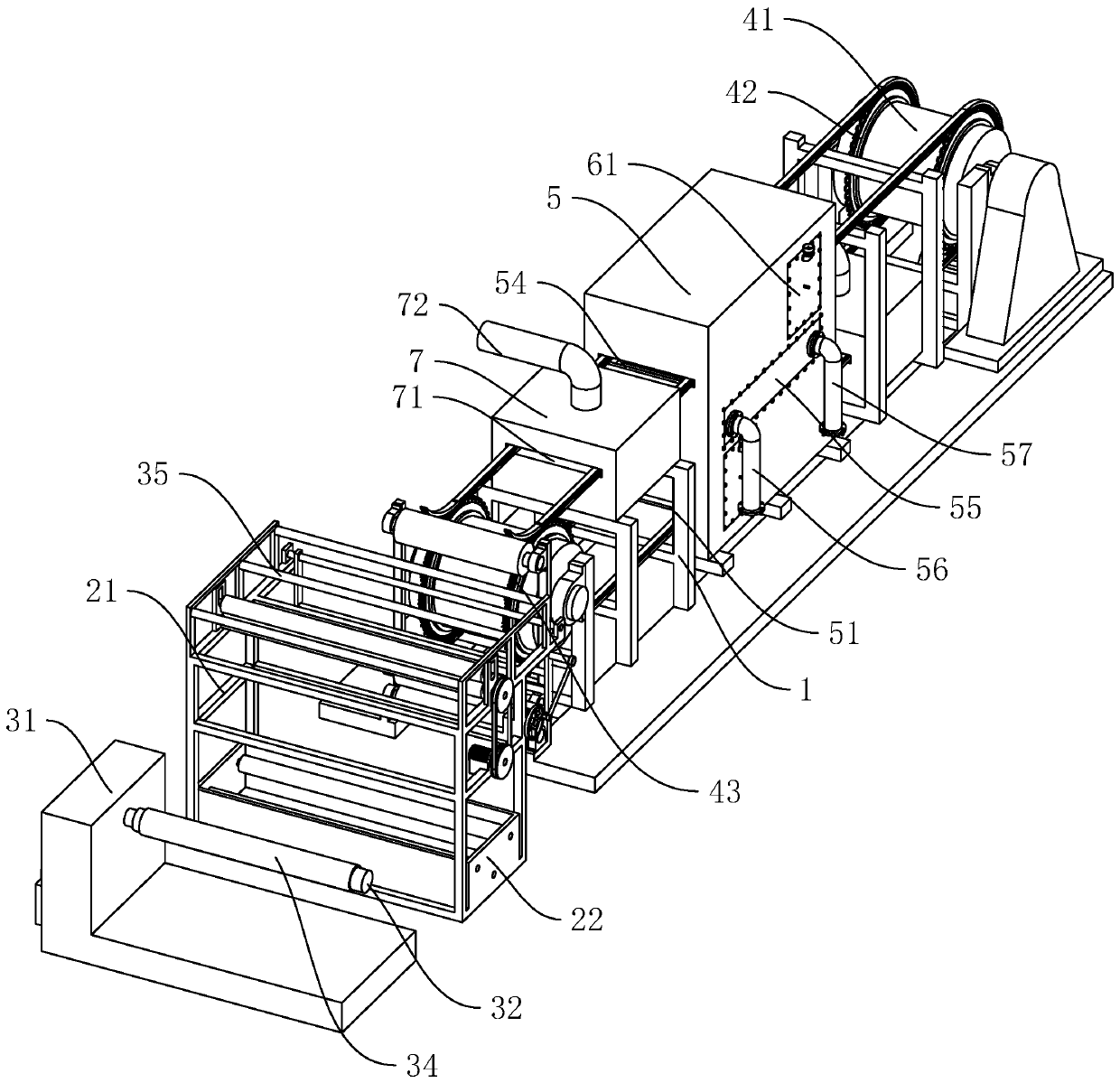

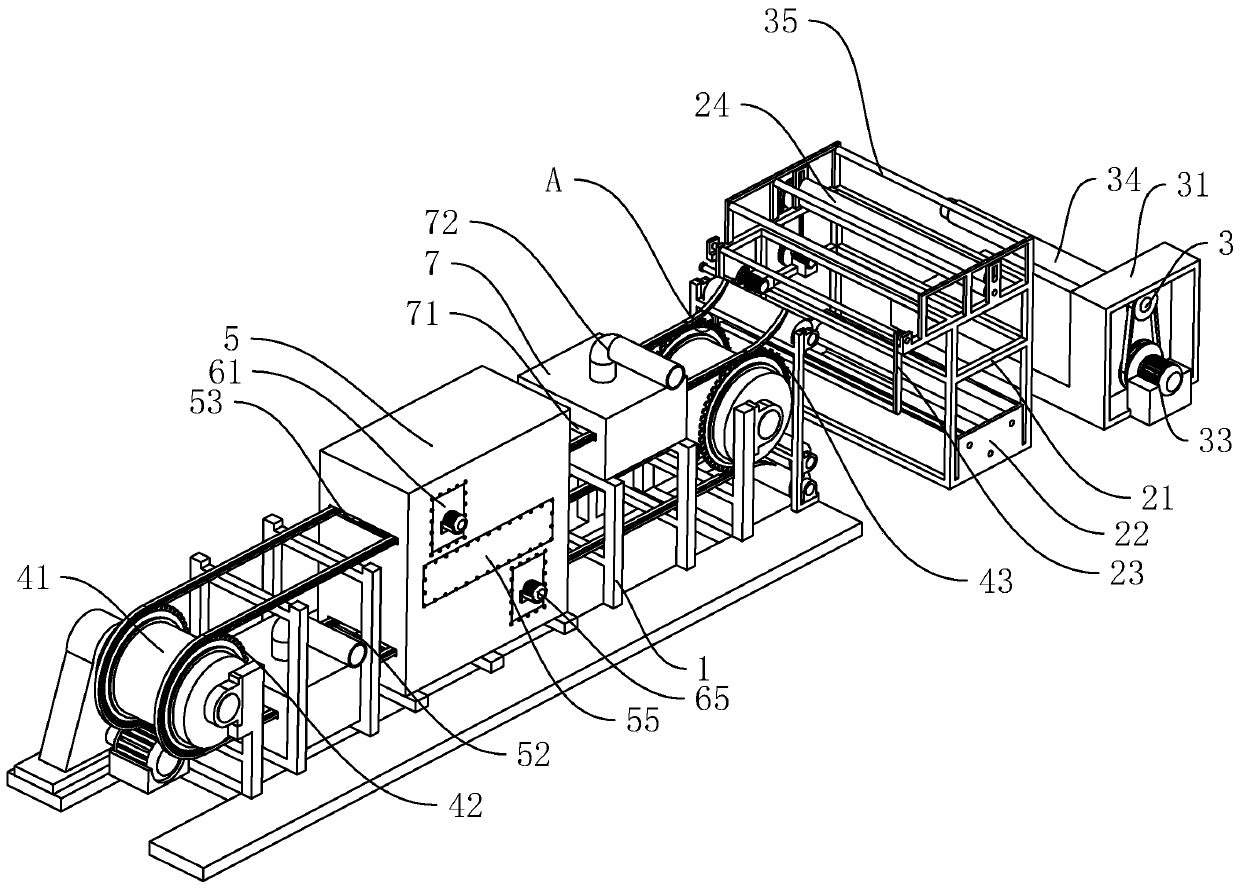

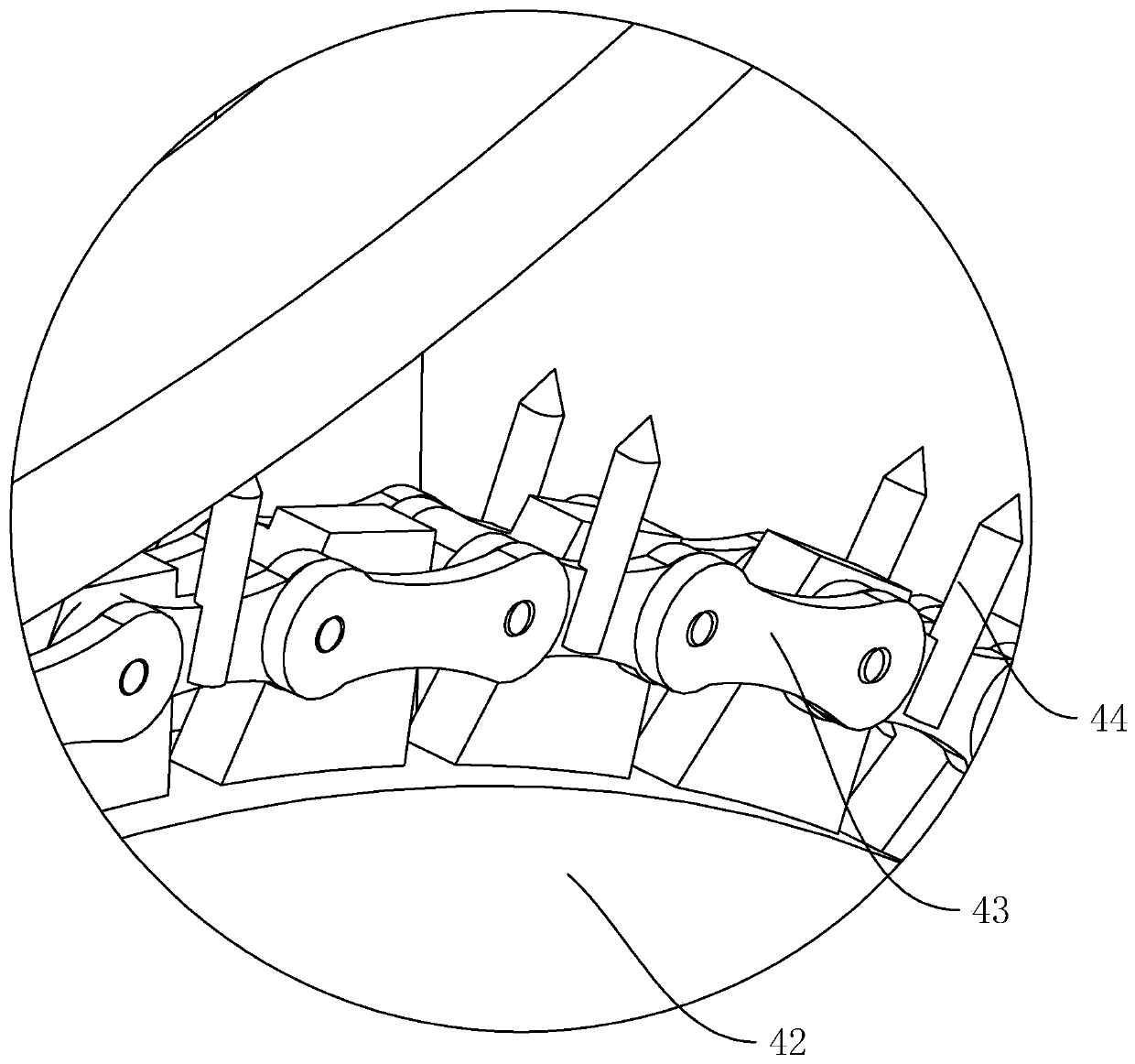

[0042] A fabric double side coating machine, such as figure 1 , figure 2 , image 3 As shown, it includes a main frame 1, an uncoiling feeding mechanism, a winding mechanism, a reversing conveying mechanism, a heating chamber 5, two coating mechanisms and two cooling chambers 7; The large-diameter roller 41, the sprocket wheel 42 fixed on the two ends of the large-diameter roller 41, and the two chains 43 wound around the two large-diameter rollers 41, the chain 43 meshes with the sprocket wheel 42, and each chain link of the chain 43 Both are processed and formed with nails 44; the heating chamber 5 is arranged between two large-diameter rollers 41, and it is provided with a lower inlet 51 and a lower outlet 52 for the lower section of the chain 43 to pass through, and a lower outlet 52 for the upper section of the chain 43 to pass through. The upper inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com