Motor protection control circuit and method of clothes airing machine

A motor protection and control circuit technology, applied to alarms, instruments, etc., can solve the problems of shortened motor life, short life, unfavorable promotion of smart clothes dryers, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

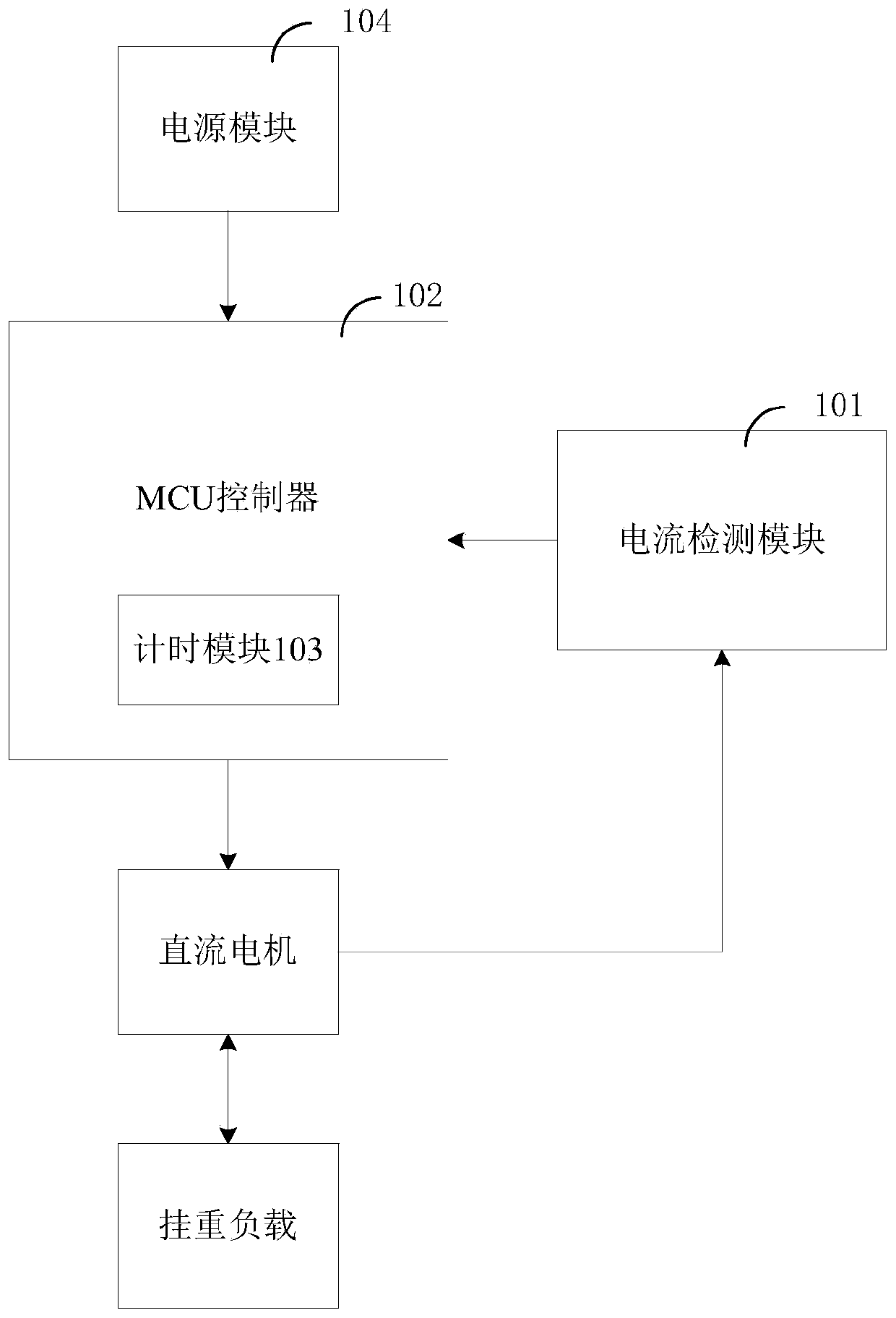

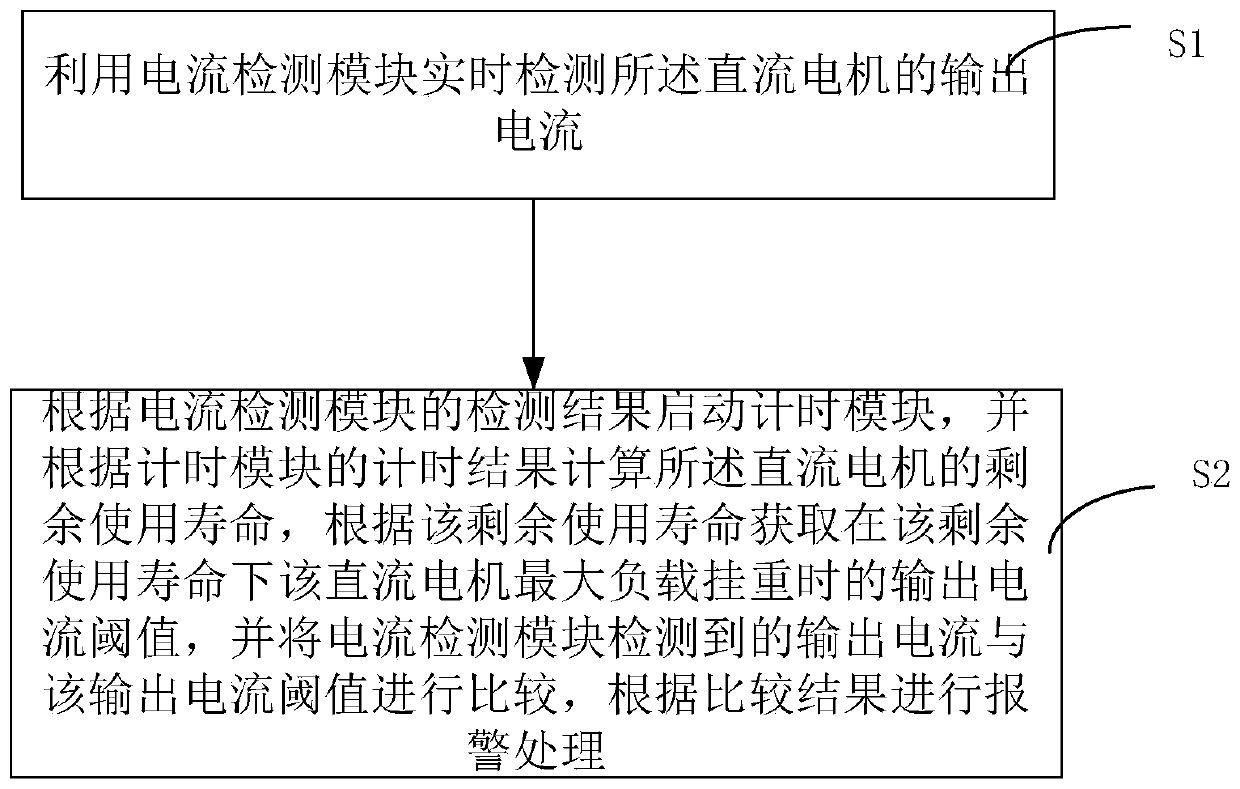

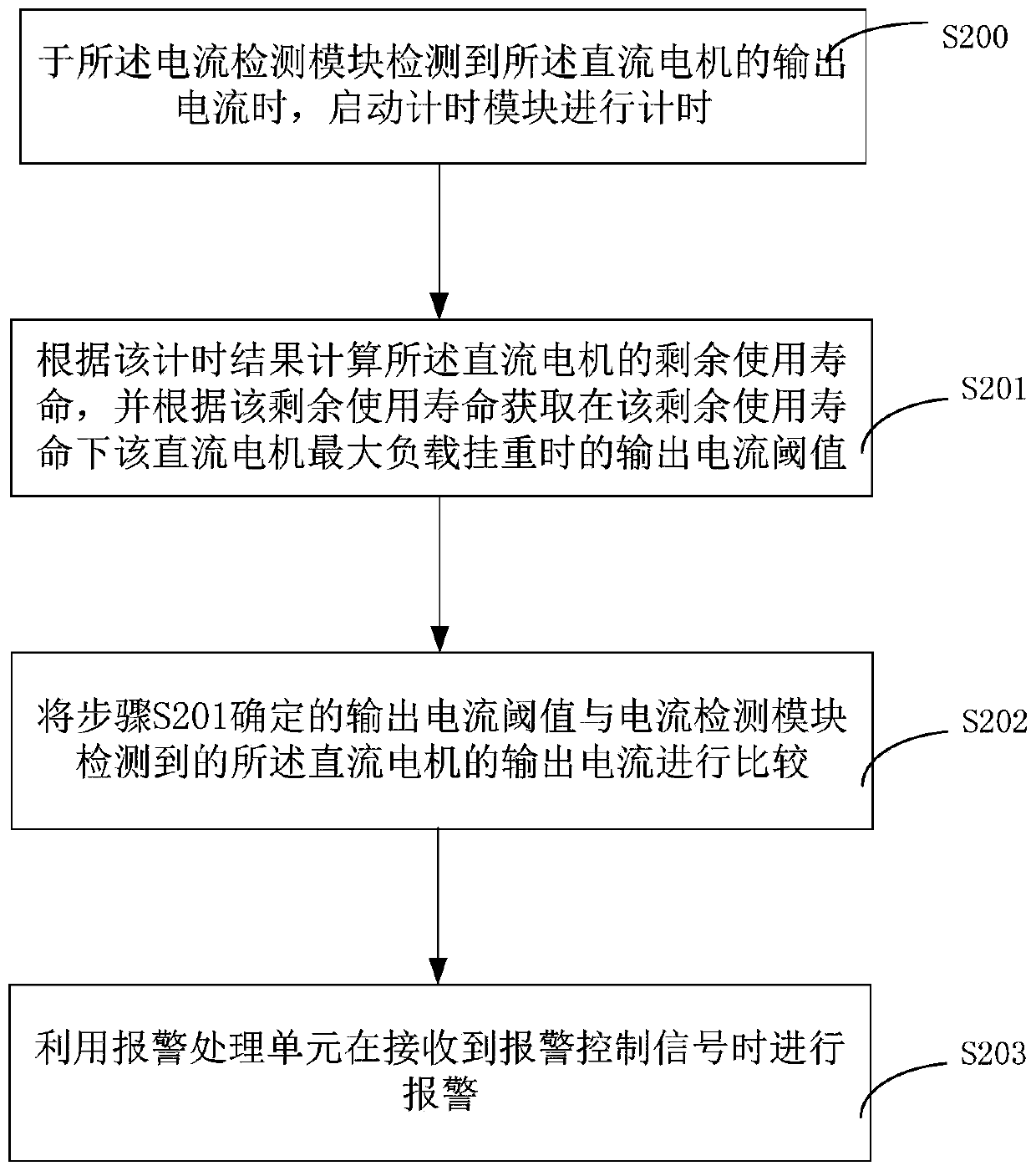

Method used

Image

Examples

Embodiment

[0055] In this embodiment, it is assumed that the maximum service life of the DC motor is x years. When the DC motor is used for the first time, that is, the service life of the DC motor is 0, the maximum load of the DC motor can be determined through the life-load-current relationship table The weight is y kilograms, and the current detection module detects that the current of the DC motor is Z amperes when the maximum load of the DC motor is suspended.

[0056] In this embodiment, when the maximum service life of the DC motor is x years, the maximum load of the DC motor is set to be y kilograms, the current of the DC motor is Z amps, and the life-suspension-current relationship table can be obtained by Established by multiple experiments, in the specific embodiment of the present invention, the relationship between the remaining life of the DC motor, the maximum load, and the current is shown in Table 1 below. When the remaining life is P i When x, set the hanging load thres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com